In essence, a C-frame press is a versatile and common machine tool defined by its characteristic C-shaped frame. This design leaves the front and sides of the working area open, providing exceptional access for loading materials, changing tooling, and integrating automation. They are powered either hydraulically or mechanically to perform a wide range of forming, punching, and assembly operations.

The central concept to grasp is the C-frame's inherent trade-off: its open design offers unmatched accessibility and versatility, but this same design can be prone to deflection ("yawning") under heavy loads, which can impact high-precision applications.

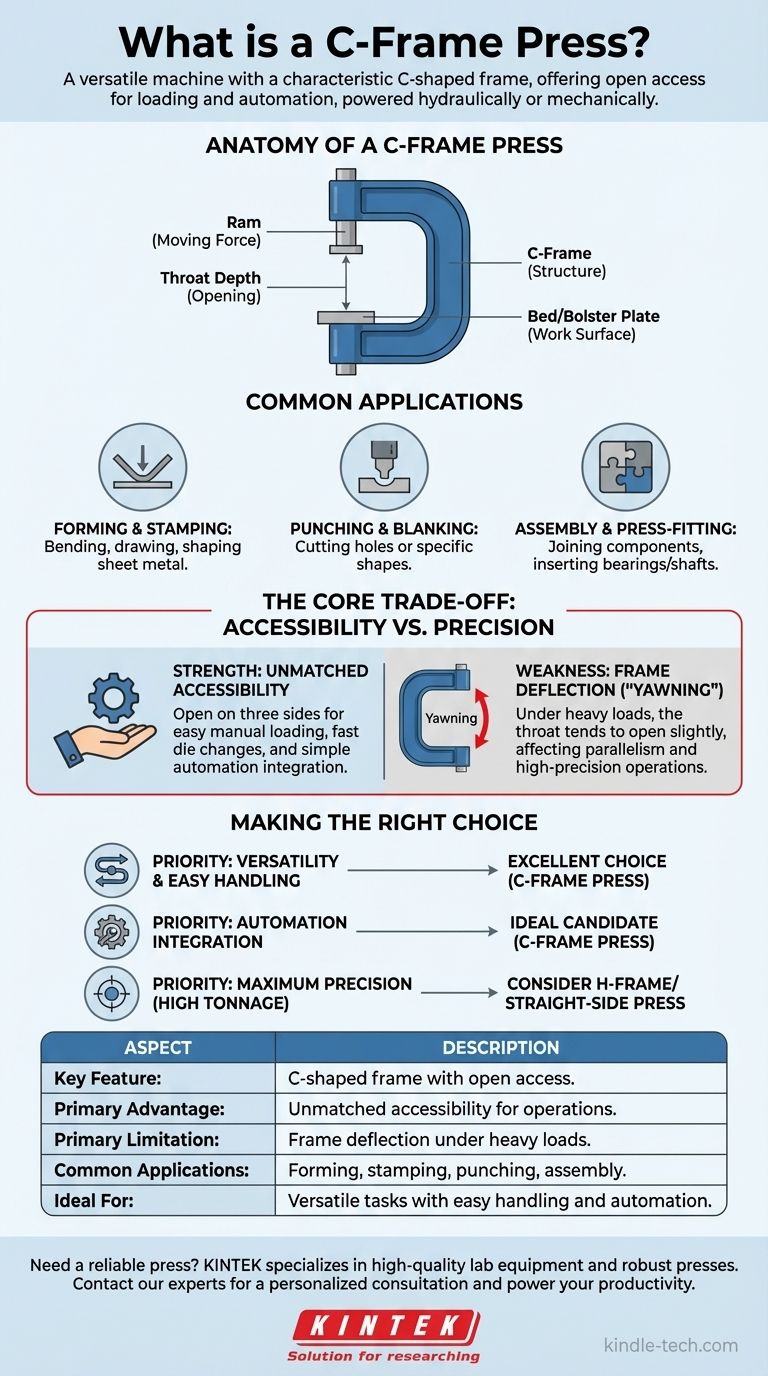

The Anatomy of a C-Frame Press

A C-frame press is often the workhorse of a fabrication shop due to its straightforward design and operational flexibility. Its construction directly influences its capabilities and limitations.

The "C" Shaped Frame

The defining feature is its frame, typically a single, solid piece of cast or welded steel shaped like the letter "C." This single-piece construction creates a "throat" or opening where the work is performed.

Core Components

The press consists of a ram (the moving component that applies force), a stationary bed or bolster plate (the work surface), and a power system. The distance from the centerline of the ram to the back of the frame's throat is known as the throat depth.

The Open-Sided Design

Unlike presses with four columns (H-frame) or solid sides (straight-side), the C-frame design is open on three sides. This is its primary advantage, making it extremely easy for operators to manually load and unload parts or for engineers to integrate conveyors and robotic arms.

Common Applications and Use Cases

The C-frame's blend of force and accessibility makes it suitable for a wide variety of manufacturing tasks across different scales, from small benchtop models to large floor-standing machines.

Forming and Stamping

These presses are frequently used for bending, drawing, and shaping sheet metal into desired forms. The force of the ram presses a die into the material, causing it to take the shape of the tooling.

Punching and Blanking

With the proper tooling, a C-frame press can efficiently punch holes into material (punching) or cut out specific shapes from a larger sheet (blanking).

Assembly and Press-Fitting

C-frame presses are also ideal for assembly operations, such as pressing bearings into housings, inserting shafts into gears, or crimping components together.

Understanding the Trade-offs

Choosing a press requires a clear understanding of its strengths and weaknesses. The C-frame design presents one of the most fundamental trade-offs in press engineering.

The Strength: Unmatched Accessibility

The open design simplifies everything. Die changes are faster. Manual part handling is ergonomic and efficient. Integrating automated feeding and removal systems is significantly less complex than with a closed-frame press. This often translates to lower operational costs and greater flexibility.

The Weakness: Frame Deflection ("Yawning")

The "C" shape has one inherent structural weakness. Under significant tonnage, the throat of the "C" has a tendency to open or "yawn" slightly. This angular deflection means the ram and bed are no longer perfectly parallel at the point of maximum force.

The Impact on Precision

This deflection can be a critical issue for high-precision operations like coining or bottom-stamping, where maintaining perfect tooling alignment is paramount to part quality. While features like gibs guide the ram's linear travel, they cannot prevent the frame itself from deflecting. Operations with off-center loads will exacerbate this effect.

Making the Right Choice for Your Goal

The decision to use a C-frame press hinges on a clear evaluation of your application's specific requirements for force, access, and precision.

- If your primary focus is versatility and easy part handling: The C-frame press is an excellent, cost-effective choice for general-purpose forming, assembly, and punching tasks.

- If your primary focus is integrating automation for production: The open-sided design of a C-frame makes it an ideal candidate for integration with robotic arms and conveyor systems.

- If your primary focus is maximum precision under high tonnage: You should carefully evaluate an H-frame or straight-side press, as their closed designs offer superior rigidity and minimize deflection.

Ultimately, understanding the relationship between the C-frame's open access and its potential for deflection empowers you to select the right tool for the job.

Summary Table:

| Aspect | Description |

|---|---|

| Key Feature | C-shaped frame providing open access on three sides |

| Primary Advantage | Unmatched accessibility for manual and automated operations |

| Primary Limitation | Frame deflection ("yawning") under high or off-center loads |

| Common Applications | Forming, stamping, punching, blanking, press-fitting, and assembly |

| Ideal For | Versatile tasks requiring easy part handling and automation integration |

Need a reliable press for your fabrication or assembly tasks?

KINTEK specializes in high-quality lab equipment and machinery, including robust presses designed for durability and performance. Whether you're setting up a new production line or upgrading your workshop, our team can help you select the perfect equipment to meet your specific force, precision, and automation needs.

Contact our experts today for a personalized consultation and discover how KINTEK can power your productivity.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How are laboratory hydraulic presses and powder pellet dies utilized in the assembly of all-solid-state batteries?

- What are the safety precautions of a power press? Essential Guarding & LOTO Procedures

- How is a laboratory precision hydraulic press applied in the mechanical stability research of nanocrystalline materials?

- How much pressure can a hydraulic press make? From 1 Ton to 75,000+ Tons of Force

- What is the principle of mechanical forging press? Harnessing Kinetic Energy for High-Volume Forging

- What role does a laboratory hydraulic press play in testing conductivity? Enhancing Nanoparticle Powder Analysis

- How does an industrial-grade hydraulic press ensure the accuracy of electromagnetic shielding tests? Precision Molding

- What are the failures of a hydraulic press? Prevent Downtime and Ensure Safety in Your Lab