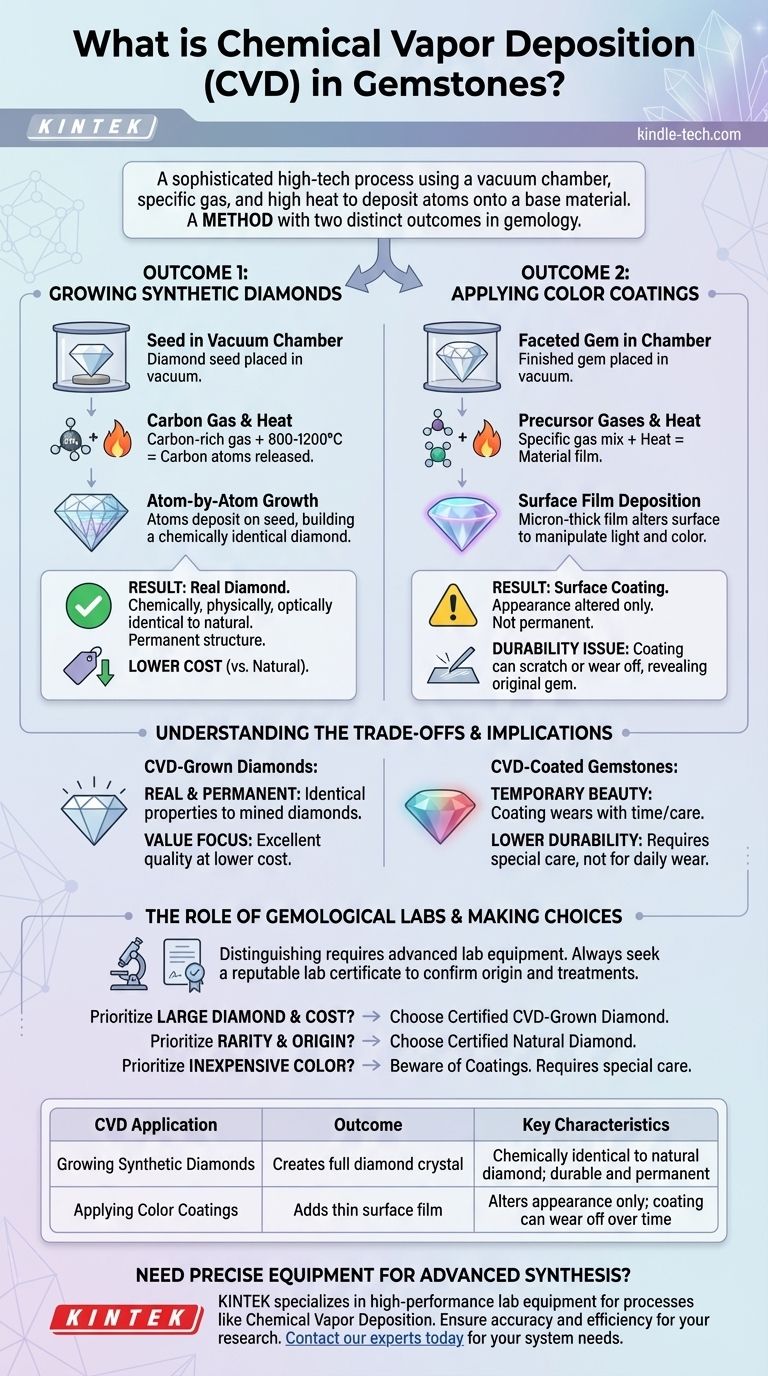

In the world of gemstones, Chemical Vapor Deposition (CVD) is a sophisticated, high-tech process used for two distinct purposes: growing an entire synthetic gemstone from scratch or applying a very thin film to an existing gem to alter its color. In both applications, the process involves placing a base material into a vacuum chamber, introducing a specific gas, and using high heat to trigger a chemical reaction. This reaction causes atoms from the gas to deposit onto the material, either growing a new crystal layer by layer or forming a surface-level coating.

The most critical thing to understand is that CVD is not a single outcome but a method. In gemology, it is most famously used to grow lab-created diamonds that are chemically identical to natural ones, but it is also used to create surface coatings that are far less durable and fundamentally different.

The Two Faces of CVD in Gemology

The term "CVD" can be confusing because it describes the process, not the product. The same foundational technology can lead to two vastly different results: a fully-formed synthetic diamond or a superficially coated gemstone.

Outcome 1: Growing Synthetic Diamonds

The primary use of CVD in the jewelry industry is to create lab-grown diamonds. This process meticulously replicates the way diamonds form, but in a controlled lab environment over a matter of weeks, not billions of years.

The process begins with a "seed," which is a very thin, flat slice of a pre-existing diamond (either natural or lab-grown). This seed is placed inside a vacuum chamber.

A carbon-rich gas, typically methane, is then introduced into the chamber and heated to extreme temperatures (around 800-1200°C). This heat breaks down the gas molecules, releasing carbon atoms.

These individual carbon atoms then "deposit" onto the diamond seed, bonding to its crystal lattice. Layer by layer, atom by atom, a new diamond crystal grows on top of the original seed, maintaining the same perfect structure.

Outcome 2: Applying Color Coatings

A different application of CVD is to apply an ultra-thin coating to the surface of a lower-value, finished gemstone to improve its appearance.

In this scenario, a faceted gem, such as a colorless topaz, is placed in the vacuum chamber. A different mix of precursor gases is introduced, designed to create a specific material film.

When heated, these gases react and deposit a durable, transparent layer onto the gem's facets. This film is engineered to manipulate light, creating the illusion of a different, more desirable color. The underlying gem is unchanged; only its surface has been altered.

Understanding the Trade-offs and Implications

Knowing whether a gem is CVD-grown or CVD-coated is essential, as the implications for value, durability, and care are completely different.

For CVD-Grown Diamonds: The Question of "Real"

A lab-grown diamond produced via CVD is chemically, physically, and optically identical to a diamond mined from the earth. It is a real diamond, simply with a different origin story.

The primary trade-off is one of market value and rarity. Because they can be produced on demand, lab-grown diamonds are significantly less expensive than natural diamonds of comparable size and quality.

For CVD-Coated Gemstones: The Durability Issue

This is the most significant pitfall. While often marketed as durable, these coatings are only microns thick. They can be scratched or worn away over time through normal wear, harsh cleaning, or repolishing.

When the coating is damaged, the original, often less desirable color of the underlying gemstone is revealed. This makes coated gems a poor choice for pieces intended for daily, long-term wear, as their beauty can be temporary.

The Role of Gemological Labs

Distinguishing between these different products is impossible for the untrained eye. Reputable gemological laboratories can easily identify natural diamonds, lab-grown diamonds, and coated gemstones using advanced testing equipment. A certificate from a trusted lab is the only way to be certain of a gemstone's origin and whether it has been treated.

Making the Right Choice for Your Goal

Your decision should be guided by your priorities, whether they are budget, durability, or the story behind the stone.

- If your primary focus is obtaining a large, high-quality diamond at a lower cost: A certified, lab-grown CVD diamond is an excellent choice, as it is a real diamond in every measurable way.

- If your primary focus is the rarity and geological origin of a stone: You should seek a certified natural diamond and be prepared for a higher price reflecting its scarcity.

- If you are considering a vibrantly colored but inexpensive gemstone: You must ask if it is coated. A CVD-coated gem requires special care and lacks the long-term durability and value of an untreated stone.

Understanding the technology behind a gemstone empowers you to look beyond the sparkle and assess its true origin and long-term value.

Summary Table:

| CVD Application | Outcome | Key Characteristics |

|---|---|---|

| Growing Synthetic Diamonds | Creates a full diamond crystal | Chemically identical to natural diamond; durable and permanent |

| Applying Color Coatings | Adds a thin surface film | Alters appearance only; coating can wear off over time |

Need precise, reliable equipment for advanced material synthesis? KINTEK specializes in high-performance lab equipment and consumables for processes like Chemical Vapor Deposition. Whether you're growing synthetic crystals or developing thin-film coatings, our solutions ensure accuracy, repeatability, and efficiency for your laboratory's most demanding projects. Contact our experts today to find the perfect system for your research or production needs!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What are the advantages of chemical vapour deposition? Achieve Superior, Conformal Coatings for Complex Parts

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- What is LPCVD used for? Achieve Perfect Conformal Films for Semiconductors & MEMS

- What are the atmosphere control requirements for CVD of silica/SiC nanowires? Master 1100°C Precursor Management

- What is the application of protective coating? Enhance Durability and Aesthetics for Your Products

- How to do physical vapor deposition? A Guide to PVD Coating Techniques and Processes

- What is the process of CVD reaction? A Step-by-Step Guide to High-Performance Coating

- What is the process of deposition precipitation? A Guide to Thin Film Deposition Fundamentals