In essence, Cold Isostatic Pressing (CIP) is a manufacturing process used to compact powders into a solid, uniform mass. Its applications are incredibly diverse, ranging from forming high-performance ceramic and metal components to creating refractory materials, artificial bones, and even sterilizing food products under immense pressure.

The core problem Cold Isostatic Pressing solves is the creation of parts with highly uniform density. By applying pressure equally from all directions, it overcomes the limitations of traditional pressing methods, especially for components that are large, complex, or made from difficult-to-process materials.

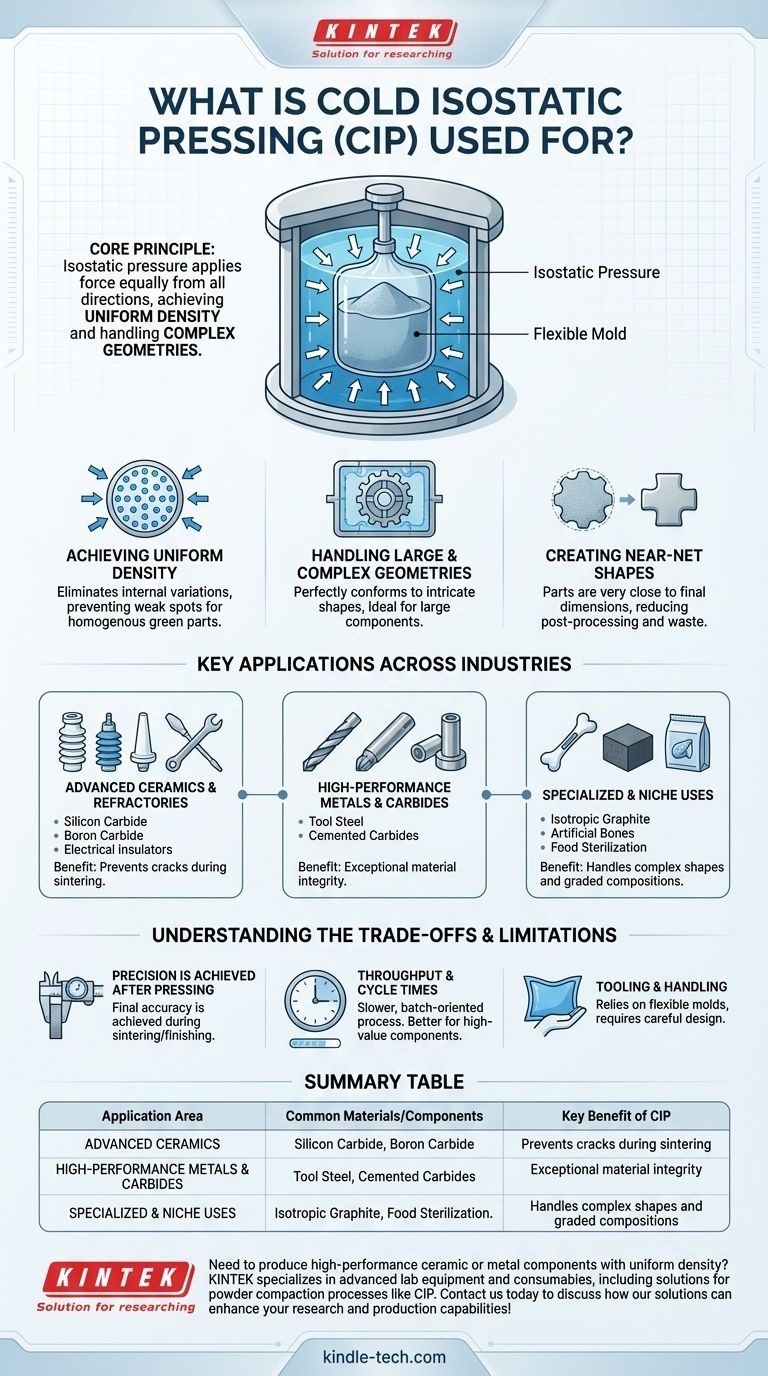

The Core Principle: Why Isostatic Pressure Matters

To understand CIP's applications, you must first grasp its fundamental advantage: the use of isostatic pressure. Unlike uniaxial pressing, which applies force from one or two directions, CIP submerges a powder-filled, flexible mold into a liquid and pressurizes the liquid.

Achieving Uniform Density

The liquid transmits pressure equally and simultaneously to every surface of the mold. This eliminates the internal density variations and potential weak spots common in parts made with directional pressing, resulting in a homogenous "green" part before final sintering.

Handling Large and Complex Geometries

Because the pressure is applied by a fluid, it can perfectly conform to intricate shapes. This makes CIP ideal for producing components that are too large or geometrically complex to be formed in a rigid die press.

Creating Near-Net Shapes

The process creates parts that are very close to their final desired dimensions. This near-net shape capability significantly reduces the need for expensive and time-consuming post-processing and machining, minimizing material waste.

Key Applications Across Industries

CIP's ability to produce uniformly dense parts from powders has made it indispensable in numerous high-performance sectors.

Advanced Ceramics and Refractories

This is a primary application for CIP. It is used to consolidate brittle and hard-to-press materials like silicon carbide, silicon nitride, boron carbide, and electrical insulators. The uniform density is critical for preventing cracks and defects during the high-temperature sintering phase.

High-Performance Metals and Carbides

CIP is increasingly used for manufacturing components from tool steel, cemented carbides, and other high-melting-point metals. Common applications include wear-resistant parts and metal forming tools that demand exceptional material integrity.

Specialized and Niche Uses

The versatility of CIP extends to less obvious fields. It is used for producing isotropic graphite, creating graded compositions or transition joints between dissimilar materials, and even for cold sterilization in the food, pharmaceutical, and chemical industries by using extreme pressure to neutralize microbes.

Understanding the Trade-offs and Limitations

While powerful, CIP is not the universal solution for all powder compaction needs. Understanding its limitations is key to using it effectively.

Precision is Achieved After Pressing

A critical point is that CIP parts do not have high dimensional precision in their pre-sintered state. The flexible mold allows for some variation. Final dimensional accuracy is achieved during the subsequent sintering and finishing steps.

Throughput and Cycle Times

Compared to high-speed uniaxial pressing used for simple parts like tablets, CIP is generally a slower, batch-oriented process. It is better suited for high-value components where material properties are more critical than mass production speed.

Tooling and Handling

The process relies on flexible, elastomeric molds or bags rather than hard steel dies. While this enables complex shapes, the tooling requires careful design and handling, and its lifespan is a different consideration than that of rigid tooling.

Making the Right Choice for Your Goal

Selecting the right compaction technology depends entirely on the specific requirements of your component and production goals.

- If your primary focus is achieving maximum uniform density in a large or complex part: CIP is almost certainly the correct technology to evaluate.

- If your primary focus is the high-volume, low-cost production of simple shapes: Traditional uniaxial or die pressing will likely be more efficient and economical.

- If your primary focus is processing advanced ceramics or refractory metals that fail with other methods: CIP offers a robust solution for creating defect-free green parts.

Ultimately, understanding that Cold Isostatic Pressing excels at creating homogeneity is the key to leveraging its full potential.

Summary Table:

| Application Area | Common Materials/Components | Key Benefit of CIP |

|---|---|---|

| Advanced Ceramics | Silicon Carbide, Boron Carbide, Insulators | Uniform density prevents cracks during sintering |

| High-Performance Metals | Tool Steel, Cemented Carbides, Wear Parts | Exceptional material integrity and strength |

| Specialized Uses | Isotropic Graphite, Artificial Bones, Food Sterilization | Handles complex shapes and graded compositions |

Need to produce high-performance ceramic or metal components with uniform density?

KINTEK specializes in providing advanced lab equipment and consumables, including solutions for powder compaction processes like Cold Isostatic Pressing. Our expertise helps laboratories and manufacturers achieve superior material properties and part integrity for complex geometries.

Contact us today to discuss how our solutions can enhance your research and production capabilities!

Visual Guide

Related Products

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- Why is cold isostatic pressing applied following steel mold dry pressing in 8YSZ? Enhance Density and Crack Prevention

- What advantages does Cold Isostatic Pressing (CIP) offer for nickel-alumina composites? Enhance Density & Strength

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- What role does a Cold Isostatic Press (CIP) play in aluminum matrix composites? Achieve 90% Density for Better Hot Pressing

- What is the function of a Cold Isostatic Press (CIP) in the fabrication of pouch-type all-solid-state batteries?

- What role does an industrial-grade omnidirectional press play in the preparation of ultra-fine grained VT6 titanium?

- Why is a Cold Isostatic Press (CIP) Required for NaSICON? Achieve Maximum Green Density and Ionic Conductivity

- Why is cold working better than hot working? A Guide to Choosing the Right Metal Forming Process