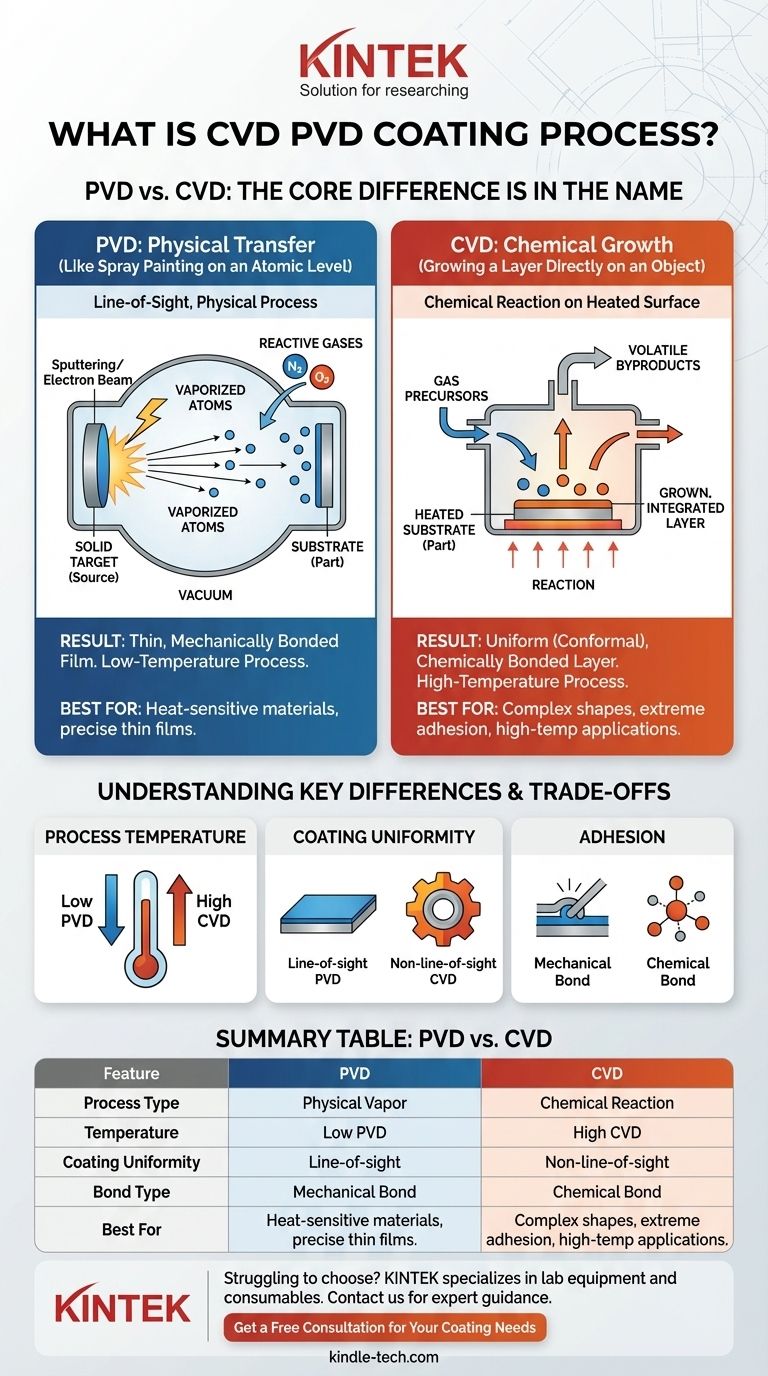

At its core, the difference is in the name. The PVD (Physical Vapor Deposition) process physically transfers a solid material onto a substrate, while the CVD (Chemical Vapor Deposition) process uses chemical reactions to grow a new layer on the substrate's surface. PVD is like spray painting on an atomic level, whereas CVD is more like causing a material to grow directly onto an object.

The fundamental distinction is how the coating material arrives and bonds to the part. PVD is a line-of-sight, physical process involving the vaporization and deposition of a solid. CVD is a chemical process where gases react and decompose on a heated surface to form the coating.

How PVD Works: A Physical Transformation

Physical Vapor Deposition covers a group of vacuum deposition methods where a solid material is vaporized, travels through a vacuum, and condenses on a substrate.

The Principle: From Solid to Vapor

The entire process occurs within a high-vacuum chamber to ensure purity and prevent contamination.

A solid source material, known as the target, is bombarded with energy. This can be achieved through methods like ion bombardment (sputtering), a high-energy electron beam, or a cathodic arc, which vaporizes the target atom by atom.

The Deposition: Atom by Atom

This vaporized material travels in a straight line through the vacuum and deposits onto the surface of the part being coated. This atom-by-atom deposition creates a very thin, highly adhered, and dense film.

To modify the coating's properties, such as hardness or color, reactive gases like nitrogen or oxygen can be introduced into the chamber. These gases react with the metal vapor as it deposits on the part.

The Result: A Thin, Bonded Film

The resulting PVD coating is a mechanically bonded layer that is extremely hard and wear-resistant. The process is typically performed at lower temperatures than CVD, making it suitable for a wider range of substrate materials.

How CVD Works: A Chemical Reaction

Chemical Vapor Deposition creates a coating through a fundamentally different mechanism. Instead of physically transferring a solid, it builds a layer from reactive gases.

The Principle: Building with Chemical Precursors

In the CVD process, the substrate is placed inside a reaction chamber and heated to a high temperature.

A carefully controlled mixture of volatile gases, known as precursors, is introduced into the chamber. These precursors contain the elements required to form the final coating.

The Reaction at the Surface

The high temperature of the substrate energizes the precursor gases, causing them to react or decompose directly on the part's surface. This chemical reaction forms a new, solid material layer that "grows" on the substrate.

Volatile byproducts from the reaction are then purged from the chamber and managed to prevent environmental impact.

The Result: A Grown, Integrated Layer

Because the coating is formed by a gas-phase reaction, it is not a line-of-sight process. This allows CVD to produce highly uniform (conformal) coatings, even on complex shapes and internal surfaces.

Understanding the Key Differences & Trade-offs

The choice between PVD and CVD is driven by the application's specific requirements, particularly temperature constraints and part geometry.

Process Temperature

CVD is a high-temperature process, typically requiring the substrate to be heated significantly to activate the chemical reactions. This limits its use to materials that can withstand these temperatures without being damaged or distorted.

PVD is a low-temperature process in comparison. This makes it ideal for coating heat-sensitive materials, including many steels, alloys, and even some plastics.

Coating Uniformity and Geometry

CVD excels at coating complex shapes uniformly. Because the precursor gases flow around the entire part, it can create a consistent coating thickness on intricate surfaces, inside bores, and in sharp corners.

PVD is a line-of-sight process. This can make it challenging to achieve a uniform coating on complex, three-dimensional parts without sophisticated fixturing and rotation during the process.

Adhesion and Material Properties

Both processes can produce coatings with excellent adhesion and desirable properties like hardness and wear resistance. However, the chemical bond formed in CVD often results in exceptional adhesion, as the coating is essentially grown into the substrate's surface layer.

Making the Right Choice for Your Application

Ultimately, the best process depends entirely on your project's goals and material constraints.

- If your primary focus is coating heat-sensitive materials: PVD is the superior choice due to its significantly lower process temperatures.

- If your primary focus is achieving a uniform coating on complex geometries: CVD is often the better option due to its non-line-of-sight, gas-phase deposition.

- If your primary focus is extreme hardness and wear resistance on a heat-tolerant material: Both processes are strong contenders, and the decision may come down to the specific coating material and cost.

Understanding the core mechanism—physical transfer versus chemical growth—is the key to selecting the right technology for your needs.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical transfer of solid material | Chemical reaction of gases |

| Temperature | Lower temperature (suitable for heat-sensitive materials) | High temperature (requires heat-tolerant substrates) |

| Coating Uniformity | Line-of-sight (may require rotation for complex parts) | Excellent uniformity on complex geometries & internal surfaces |

| Bond Type | Mechanical bond | Chemical bond (grown into substrate) |

| Best For | Heat-sensitive materials, precise thin films | Complex shapes, extreme adhesion, high-temperature applications |

Struggling to choose between PVD and CVD for your lab equipment or components? KINTEK specializes in lab equipment and consumables, providing expert guidance and solutions for all your coating needs. Our team can help you select the ideal process to enhance durability, performance, and efficiency for your specific application. Contact us today to discuss your project requirements and discover how our expertise can benefit your laboratory.

Get a Free Consultation for Your Coating Needs

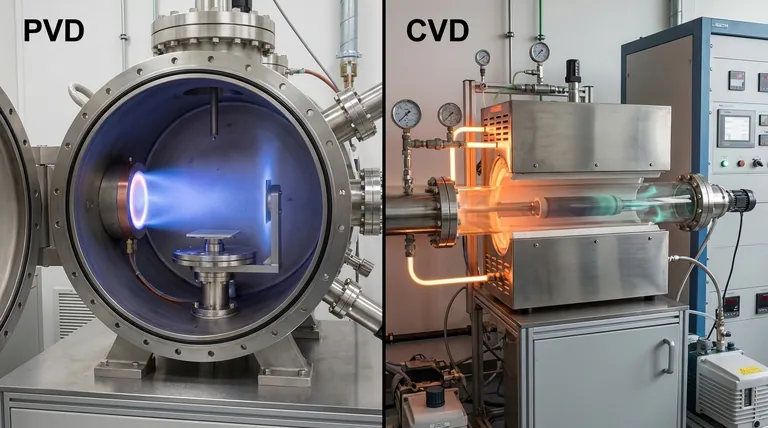

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What are the challenges of carbon nanotubes? Overcoming Production and Integration Hurdles

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What are nanotubes drawbacks? The 4 Major Hurdles Limiting Their Real-World Use

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- How do nanotubes affect the environment? Balancing Low Carbon Footprint with Ecological Risks