At their core, PVD and CVD are two distinct families of vacuum deposition techniques used to apply thin film coatings. The fundamental difference lies in their state of matter and mechanism: Physical Vapor Deposition (PVD) physically transfers a solid material into a vapor that condenses on a substrate, while Chemical Vapor Deposition (CVD) uses precursor gases that chemically react on the substrate's surface to form the solid film.

The choice between PVD and CVD hinges on a critical trade-off between process temperature and coating conformity. PVD is a lower-temperature, line-of-sight process ideal for heat-sensitive components, while CVD is a high-temperature process that uses chemical reactions to create highly uniform coatings, even on complex shapes.

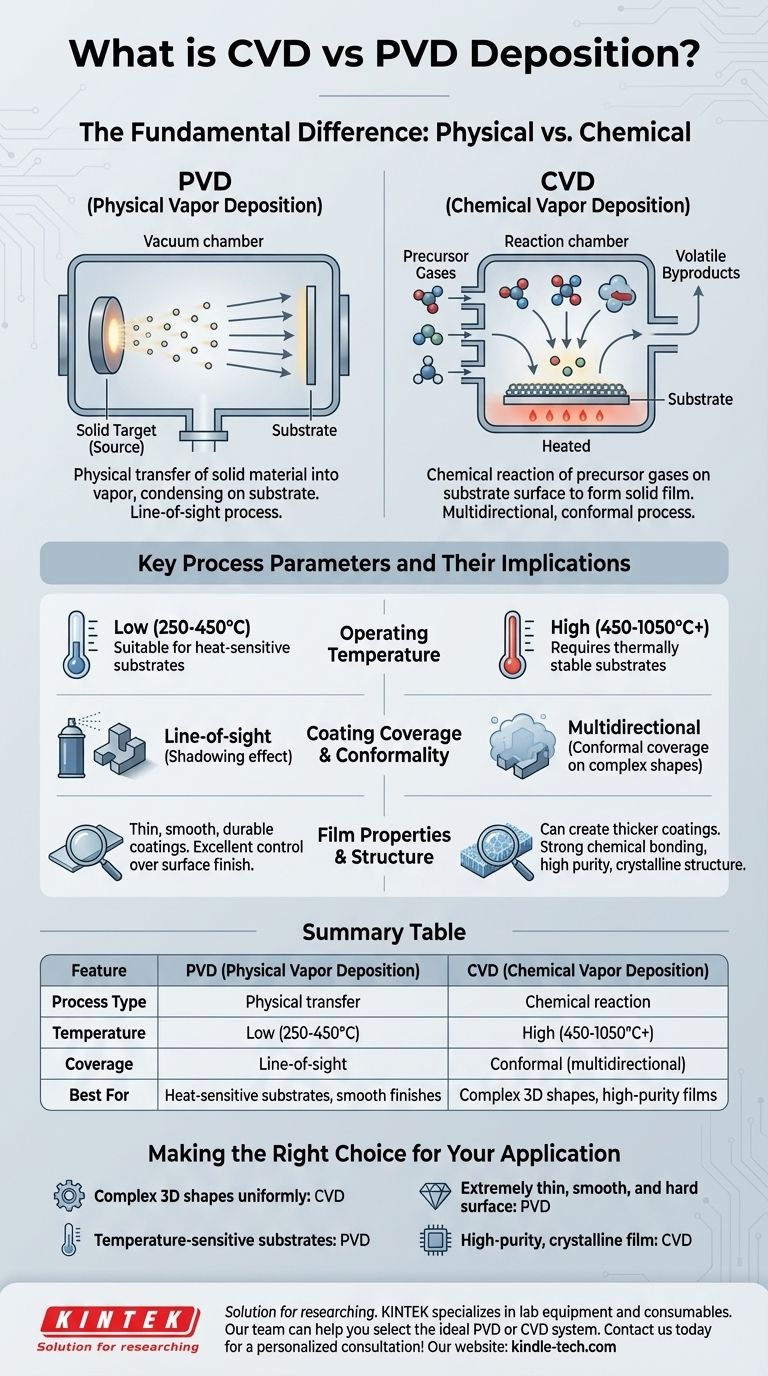

The Fundamental Difference: Physical vs. Chemical

Understanding how each process works reveals its inherent strengths and weaknesses. The names themselves—Physical Vapor Deposition and Chemical Vapor Deposition—point to their core operational principle.

PVD: The Physical Deposition Process

In PVD, a solid source material, known as a "target," is vaporized within a vacuum chamber through methods like sputtering or thermal evaporation.

This vaporized material travels in a straight line and condenses directly onto the substrate, forming a thin, dense film. No chemical reaction occurs with the substrate itself; it is a purely physical transfer and condensation.

CVD: The Chemical Reaction Process

CVD introduces one or more volatile precursor gases into a reaction chamber.

These gases decompose and react on the heated surface of the substrate, forming a solid film. This process creates volatile byproducts that are then exhausted from the chamber. The coating is a result of a new chemical compound being synthesized directly on the part's surface.

Key Process Parameters and Their Implications

The operational differences between PVD and CVD directly impact the materials you can use, the shapes you can coat, and the final properties of the film.

Operating Temperature

PVD is a comparatively low-temperature process, typically operating between 250°C and 450°C. This makes it suitable for coating materials that cannot withstand high heat.

CVD is a high-temperature process, often requiring temperatures from 450°C to over 1050°C to drive the necessary chemical reactions. This limits its use to substrates that are thermally stable at these elevated temperatures.

Coating Coverage and Conformality

PVD is a line-of-sight process. Like a can of spray paint, it can only coat the surfaces it can "see" from the source. This can create a "shadowing" effect on complex geometries, leaving some areas uncoated.

CVD is a multidirectional process. Because the reactive gases fill the entire chamber, they can deposit a highly uniform, or "conformal," coating on all exposed surfaces, including intricate internal passages and complex 3D shapes.

Understanding the Trade-offs

Neither method is universally superior. The optimal choice depends entirely on the specific requirements of the application, which involves balancing the benefits and limitations of each.

Film Thickness and Smoothness

PVD processes generally produce thin, very smooth, and durable coatings. The physical condensation process allows for fine control over the surface finish.

CVD can be used to create thicker coatings. However, depending on the specific chemistry and process parameters, the resulting film can sometimes be rougher than a typical PVD coating.

Material Adhesion and Structure

CVD often results in excellent adhesion because the film is chemically bonded to the substrate. The process is ideal for producing high-purity, high-performance crystalline structures, which is why it's a cornerstone of the semiconductor industry.

PVD adhesion is more mechanical, though it is typically very strong and durable for a wide range of applications, especially for wear-resistant coatings on tools.

Process Complexity and Environment

PVD is a physically clean process, vaporizing a solid into a solid film with few byproducts.

CVD processes are more complex, often involving volatile, toxic, or corrosive precursor gases and creating hazardous byproducts that must be carefully managed and exhausted.

Making the Right Choice for Your Application

Selecting the correct technology requires matching your primary goal to the strengths of the process.

- If your primary focus is coating complex 3D shapes uniformly: CVD is the superior choice due to its non-line-of-sight, conformal nature.

- If you are working with temperature-sensitive substrates (like certain alloys or polymers): PVD's lower operating temperatures make it the far more suitable, and often only, viable option.

- If you require an extremely thin, smooth, and hard surface (for decorative finishes or cutting tools): PVD is often preferred for its exceptional control over film smoothness and density.

- If your goal is to grow a high-purity, crystalline film (as in semiconductor manufacturing): CVD is the industry standard for this type of precise material synthesis.

Understanding these core principles is the key to selecting the deposition technology that aligns perfectly with your material, geometry, and performance goals.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical transfer | Chemical reaction |

| Temperature | Low (250-450°C) | High (450-1050°C+) |

| Coverage | Line-of-sight | Conformal (multidirectional) |

| Best For | Heat-sensitive substrates, smooth finishes | Complex 3D shapes, high-purity films |

Still unsure which deposition process is right for your application? KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert guidance on thin film coating solutions. Our team can help you select the ideal PVD or CVD system based on your substrate, geometry, and performance requirements. Contact us today for a personalized consultation!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the precursor gas in PECVD? The Key to Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- Why is PECVD better than CVD? Achieve Superior Low-Temperature Thin Film Deposition

- How plasma is generated in PECVD? A Step-by-Step Breakdown of the Process

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method