At the heart of creating precise dental restorations lies a process of controlled, intense heat. A dental burnout furnace is a specialized, high-temperature oven designed for the critical "burnout" or "dewaxing" stage in a dental laboratory. It systematically melts and eliminates a wax pattern from an investment mold, creating a perfect negative space for casting metal alloys or pressing ceramics to form crowns, bridges, and other prosthetics.

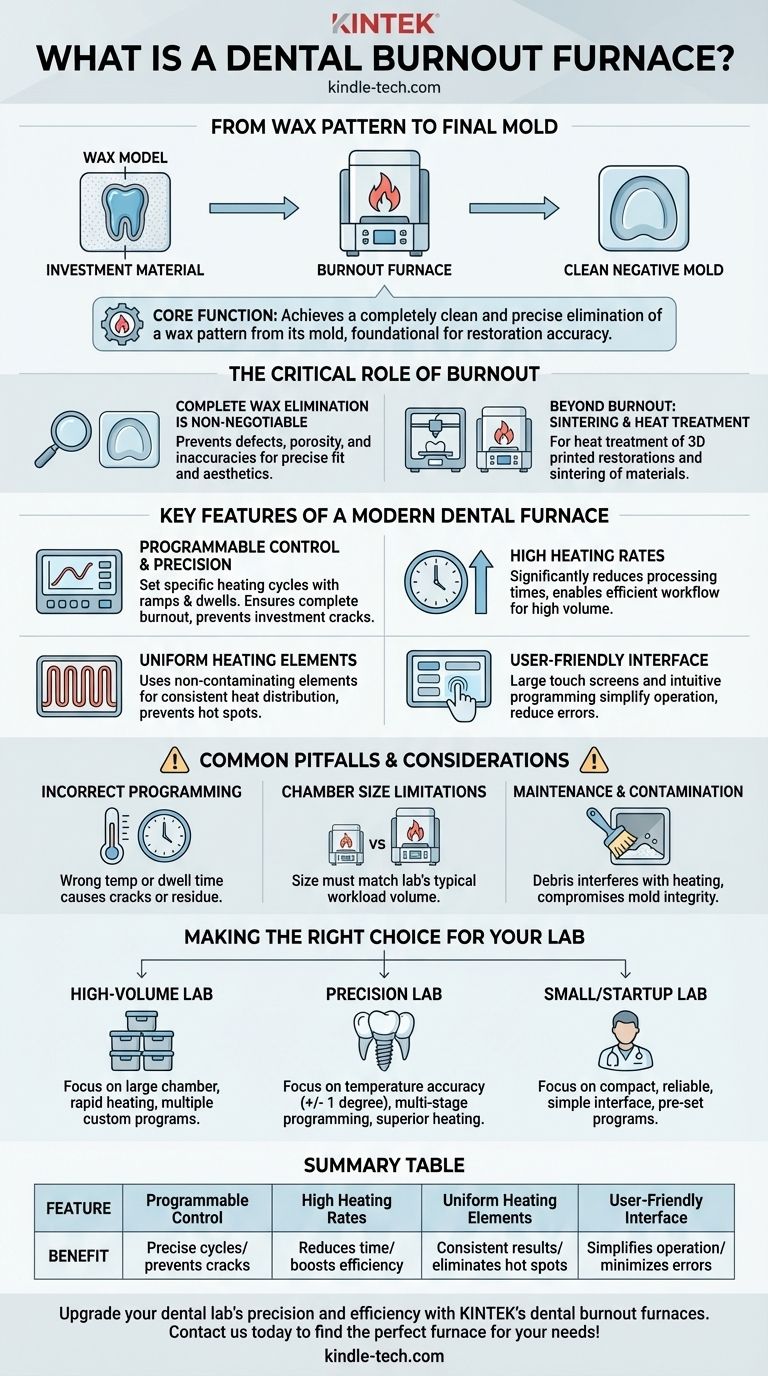

The core function of a dental burnout furnace is to achieve a completely clean and precise elimination of a wax pattern from its mold. This single step is foundational to the accuracy, fit, and ultimate success of the final dental restoration.

The Critical Role of Burnout in Dental Restorations

The burnout process is a transformative step that converts a temporary wax model into a durable, heat-resistant mold ready for casting. The furnace's performance directly impacts the quality of the final product.

From Wax Pattern to Final Mold

The process begins with a technician creating a precise wax model of the final restoration. This wax pattern is then encased in a plaster-like material called investment. Once hardened, this entire unit is placed into the burnout furnace. The furnace follows a programmed heating cycle to first melt the wax and then vaporize any remaining residue.

Why Complete Wax Elimination is Non-Negotiable

Any residual wax or carbon left inside the investment mold will cause defects, porosity, or inaccuracies in the final casting. A high-quality burnout furnace ensures a thorough and clean elimination of wax, which is essential for creating restorations with a precise fit and excellent aesthetics, ultimately improving patient satisfaction.

Beyond Burnout: Sintering and Heat Treatment

While its primary role is dewaxing, the precise temperature control of modern furnaces allows them to be used for other applications. This includes the heat treatment of restorations made with 3D metal printers or the sintering of certain dental materials, adding to their versatility in a modern lab.

Key Features of a Modern Dental Furnace

Modern burnout furnaces are engineered for precision, efficiency, and ease of use. Certain features are critical for achieving consistent, high-quality results.

Programmable Control and Precision

The most critical feature is a digital programmable controller. This allows technicians to set specific heating cycles with multiple stages (ramps and dwells), controlling how quickly the temperature rises and how long it's held. This precision, often accurate to within +/- 1 degree, is essential for preventing cracks in the investment material and ensuring a complete burnout.

High Heating Rates

A rapid heating rate significantly reduces processing times. This enables more efficient workflow management, allowing a dental lab to handle a higher volume of cases and meet tight deadlines without compromising quality.

Uniform Heating Elements

Modern furnaces often use non-contaminating silicon carbide heating elements. These are designed to distribute heat evenly throughout the chamber, preventing hot spots that could damage the investment mold and ensuring a consistent burnout for every item inside.

User-Friendly Interface

Features like large, true-color touch screens and intuitive programming simplify operation. This reduces the chance of user error and allows technicians to quickly set up and monitor the burnout cycle, with a clear display of the furnace's status.

Common Pitfalls and Considerations

While essential, the furnace is a tool that requires proper use. Understanding its limitations and potential for error is key to avoiding costly mistakes.

Incorrect Programming

Using the wrong temperature ramp or dwell time for a specific investment material is a common mistake. Heating too quickly can cause the investment to crack, while insufficient time or temperature can leave behind residue, compromising the final casting.

Chamber Size Limitations

Furnaces come in various sizes. A small, one-liter capacity chamber is ideal for a few crowns or a small bridge but is inefficient for a high-production lab. Choosing the right size is a critical decision based on a lab's typical workload.

Maintenance and Contamination

While designed to be low-maintenance, the furnace chamber and trays must be kept clean. Debris from old investment material or other contaminants can interfere with the heating process and compromise the integrity of new molds.

Making the Right Choice for Your Lab

Selecting a furnace depends entirely on the specific goals and workflow of your dental laboratory.

- If your primary focus is high-volume production: Prioritize a furnace with a larger chamber, rapid heating rates, and the capacity to store multiple custom programs.

- If your primary focus is precision and complex restorations: Seek out a model with exceptional temperature accuracy (+/- 1 degree), multi-stage programming, and superior heating elements.

- If your primary focus is a small or startup lab: A compact, reliable furnace with a simple interface and pre-set programs offers an excellent balance of performance, ease of use, and cost-effectiveness.

Ultimately, the right dental burnout furnace serves as a silent, reliable partner, ensuring the foundational accuracy that defines high-quality dental work.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Programmable Digital Control | Ensures precise heating cycles, preventing mold cracks and wax residue. |

| High Heating Rates | Reduces processing time, boosting lab efficiency and throughput. |

| Uniform Heating Elements | Eliminates hot spots, guaranteeing consistent results for every restoration. |

| User-Friendly Interface | Simplifies operation, minimizes errors, and streamlines workflow. |

Upgrade your dental lab's precision and efficiency with KINTEK's dental burnout furnaces. Our specialized lab equipment is engineered to deliver flawless wax elimination, uniform heating, and programmable control—ensuring every crown, bridge, or prosthetic meets the highest standards of fit and aesthetics. Whether you're a high-volume production lab or focused on complex restorations, KINTEK provides reliable solutions tailored to your workflow. Contact us today to find the perfect furnace for your laboratory needs!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability