At its core, direct current sintering is an advanced manufacturing technique that consolidates powders into a solid mass by passing a pulsed, high-amperage direct electrical current directly through the material. Unlike traditional methods that rely on external heating in a furnace, this process uses the material's own electrical resistance to generate heat internally and simultaneously applies mechanical pressure. This combination results in dramatically faster and more efficient densification, often at lower overall temperatures.

The critical distinction is that direct current sintering is not just a faster way to heat a material. The electrical current itself plays an active role in the consolidation process, cleaning particle surfaces and accelerating diffusion, which enables the creation of dense, high-performance materials in a fraction of the time required by conventional furnace-based methods.

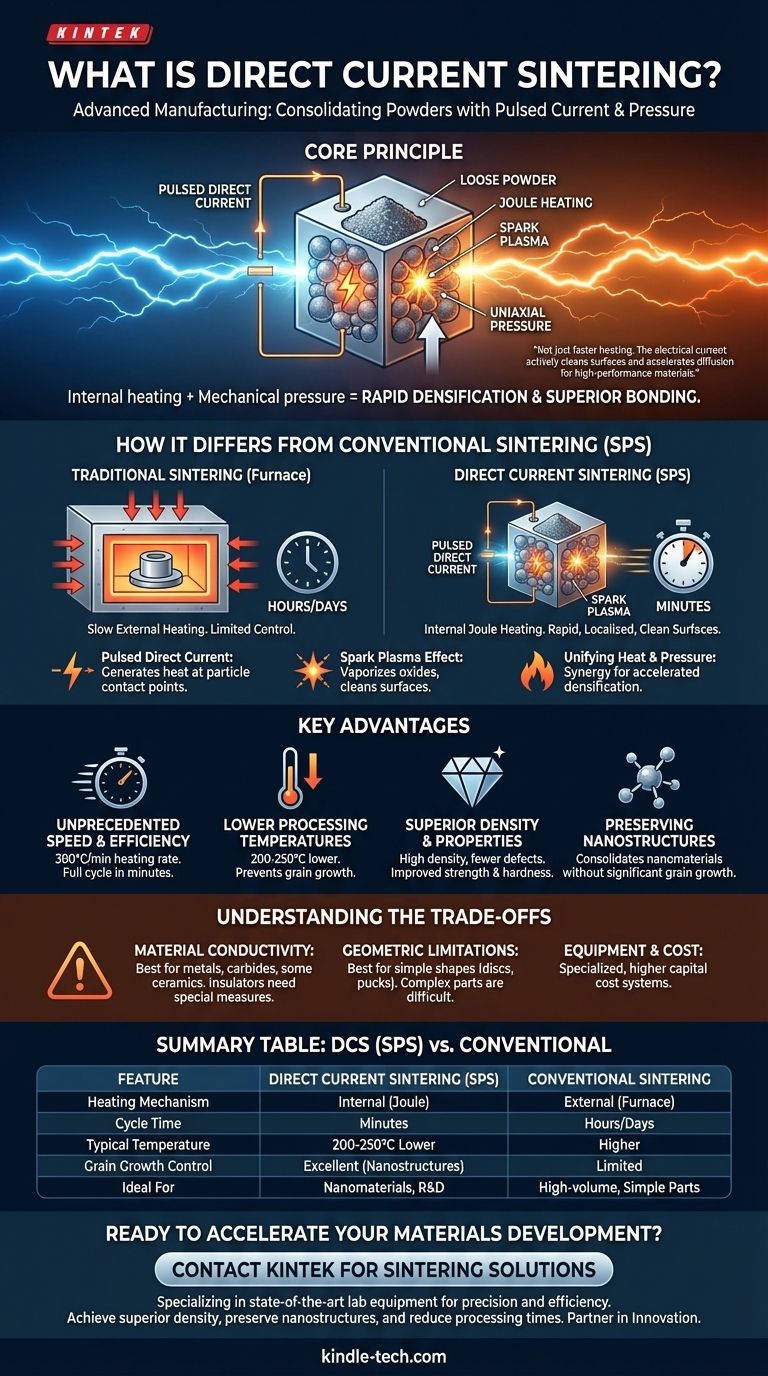

How It Differs From Conventional Sintering

Traditional sintering involves placing a pre-formed part (a "green body") into a furnace, slowly heating it for hours or even days, and allowing heat transfer to consolidate the particles. Direct current sintering, most commonly known as Spark Plasma Sintering (SPS), fundamentally changes this dynamic.

The Role of Pulsed Direct Current

In an SPS process, the loose powder is placed in a conductive die (typically graphite). Instead of heating it from the outside, a pulsed DC current is passed directly through the die and the powder itself.

This creates rapid Joule heating, where heat is generated at the contact points between individual powder particles. This heating is incredibly fast and localized exactly where it's needed most for bonding to occur.

The "Spark Plasma" Effect

The pulsed nature of the current can generate momentary spark discharges in the microscopic voids between powder particles.

This creates a localized plasma that has a critical effect: it cleans the surfaces of the particles by vaporizing adsorbed gases and breaking down oxide layers. Clean surfaces can bond together much more effectively and at lower temperatures.

Unifying Heat and Pressure

While conventional hot pressing also uses heat and pressure, SPS applies them with a unique synergy. The simultaneous application of uniaxial pressure and the internal, rapid heating forces the particles together while their surfaces are in an ideal state for bonding.

This synergy dramatically accelerates densification, the process of eliminating porosity and turning the powder into a solid object.

The Key Advantages Over Traditional Methods

The unique mechanism of direct current sintering provides several significant, measurable advantages over furnace-based techniques.

Unprecedented Speed and Efficiency

The most dramatic advantage is speed. Heating rates can exceed 300°C per minute, compared to just 5-8°C per minute in a conventional furnace.

This means a full sintering cycle can be completed in minutes, rather than the hours or days required for traditional methods, drastically increasing throughput for research and development.

Lower Processing Temperatures

Because the electrical current actively assists the bonding process, the required peak temperature is often 200°C to 250°C lower than in conventional sintering.

Lower temperatures are crucial for preventing undesirable changes in the material, such as excessive grain growth, which can degrade mechanical properties.

Superior Density and Final Properties

The combination of surface cleaning, rapid heating, and simultaneous pressure results in materials with exceptionally high density and fewer internal defects. This directly translates to improved strength, hardness, and other performance characteristics.

Preserving Nanostructures

For advanced materials science, this is a critical benefit. Conventional, long-duration heating coarsens nanomaterials, destroying their unique properties.

Direct current sintering's speed and lower temperatures make it possible to consolidate nano-sized powders into a solid part without significant grain growth, preserving the nanostructure and its enhanced properties in the final product.

Understanding the Trade-offs

While powerful, direct current sintering is not a universal solution. Understanding its limitations is key to using it effectively.

Material Conductivity Requirements

The process relies on current passing through the material. It works exceptionally well for conductive and semi-conductive materials like metals, carbides, and some ceramics.

For electrically insulating ceramics, special measures are required, such as using a conductive die to heat the sample indirectly or mixing the powder with conductive additives, which adds complexity.

Geometric and Size Limitations

SPS is typically performed in a simple, uniaxial press using a cylindrical die. This means it is best suited for producing simple shapes like discs, pucks, and rectangular blocks. Creating parts with complex geometries is difficult and often impractical.

Equipment and Cost

SPS systems are specialized machines that are more complex and carry a higher capital cost than standard high-temperature furnaces. The process is a trade-off between higher initial investment and significant gains in speed and material quality.

Is Direct Current Sintering Right for Your Application?

Choosing the right sintering method depends entirely on your material, desired outcome, and production goals.

- If your primary focus is advanced materials research (nanomaterials, composites, novel alloys): Direct current sintering is the superior choice, as its ability to preserve delicate microstructures is unparalleled.

- If your primary focus is rapid process development and material discovery: The extremely short cycle times make it ideal for quickly iterating through different compositions and processing parameters.

- If your primary focus is high-volume production of simple, established parts: Traditional powder metallurgy and furnace sintering may offer a more cost-effective solution at a massive scale.

- If your primary focus is creating large or geometrically complex parts: Methods like isostatic pressing or 3D printing followed by conventional sintering are better suited for complex shapes.

Ultimately, direct current sintering provides an exceptional level of control over the material consolidation process, enabling the creation of next-generation materials that are simply not achievable with traditional techniques.

Summary Table:

| Feature | Direct Current Sintering (SPS) | Conventional Sintering |

|---|---|---|

| Heating Mechanism | Internal (Joule heating via pulsed DC current) | External (furnace heating) |

| Cycle Time | Minutes | Hours or Days |

| Typical Temperature | 200-250°C Lower | Higher |

| Grain Growth Control | Excellent (preserves nanostructures) | Limited |

| Ideal For | Nanomaterials, composites, R&D | High-volume, simple parts |

Ready to accelerate your materials development with advanced sintering technology?

At KINTEK, we specialize in providing state-of-the-art lab equipment, including sintering solutions, to meet the demanding needs of modern laboratories. Our expertise can help you achieve superior material density, preserve delicate nanostructures, and drastically reduce your processing times.

Contact us today using the form below to discuss how our specialized equipment can bring precision and efficiency to your research and development projects. Let KINTEK be your partner in innovation.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- What are the different sintering methods? Choose the Right Technique for Your Material & Application

- What are the advantages of SPS? Achieve Superior Material Density and Performance

- What is the difference between hot press and SPS? Choose the Right Sintering Method for Your Lab

- What is the plasma sintering technique? Achieve Rapid, High-Density Material Fabrication

- What is the SPS process of spark plasma sintering? A Guide to Rapid, Low-Temperature Densification