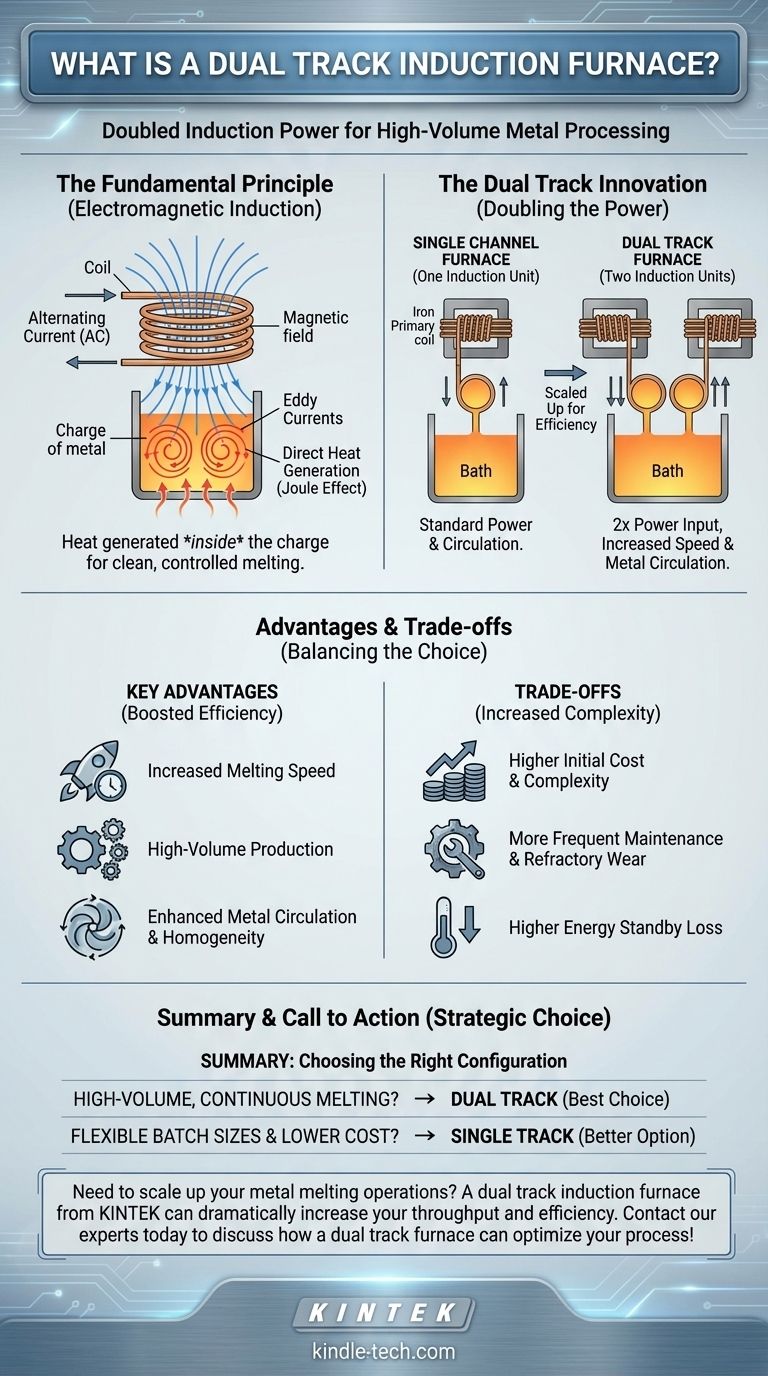

In essence, a dual track induction furnace is a specific type of channel induction furnace equipped with two separate induction units instead of the standard single unit. While a basic induction furnace uses a single coil to generate heat, a dual track design doubles this core component to significantly increase melting power, speed, and metal circulation within a single furnace shell.

A dual track furnace isn't a fundamentally different technology, but rather a scaled-up configuration of a channel induction furnace. Its purpose is to increase power input and melting efficiency for large-volume metal processing by using two heating "tracks" or loops simultaneously.

The Fundamental Principle: How Induction Furnaces Work

To understand the dual track design, we must first grasp the core principle of induction heating. It is an exceptionally clean and controlled method for melting metals.

The Core Mechanism: Electromagnetic Induction

An induction furnace uses a powerful coil, typically made of hollow copper tubing, through which an alternating current (AC) flows. This creates a strong, fluctuating magnetic field around the crucible or chamber holding the metal charge.

This magnetic field passes directly through the conductive metal inside the furnace.

Direct Heat Generation

The magnetic field induces powerful electrical currents, known as eddy currents, to flow within the metal itself. The metal's natural resistance to the flow of these currents generates immense heat through the Joule effect, causing the metal to melt rapidly.

Crucially, the heat is generated inside the charge, not by an external flame or electric arc. This minimizes heat loss and prevents contamination from combustion byproducts.

Precise Control and Purity

Because the heating is electromagnetic, the power can be regulated with extreme precision. This allows for exact temperature control, which is vital for preserving valuable and easily oxidized alloying elements. The process is clean, energy-efficient, and produces minimal waste.

From Single Channel to Dual Track

The "dual track" design is an evolution of a specific type of furnace known as a channel furnace, which operates much like a transformer.

Understanding the Channel Furnace

A channel induction furnace consists of a main bath of molten metal connected to one or more narrow channels. An induction unit, comprising an iron core and a primary coil, is looped around this channel.

In this setup, the primary coil and iron core act as the primary side of a transformer. The molten metal loop within the channel acts as the secondary coil. When current flows through the primary coil, it induces a massive current in the metal loop, generating intense heat. This hot, circulating metal then flows back into the main bath, transferring heat and stirring the entire melt.

The "Dual Track" Innovation: Doubling the Induction Unit

A dual track induction furnace simply applies this principle twice to a single furnace body. It features two separate induction units, each with its own iron core, primary coil, and dedicated channel of molten metal.

These two "tracks" work in parallel to heat the main bath of metal. This configuration allows for a much higher total power input than a single-unit design of a similar size could achieve.

Key Advantages of the Dual Design

The primary advantage is a significant boost in production efficiency. By doubling the power input, melting rates are increased, and the enhanced circulation from two channels can create a more homogenous molten bath.

This makes the design highly suitable for foundries that require high-volume, continuous, or semi-continuous melting and holding operations.

Understanding the Trade-offs

While powerful, the dual track design introduces complexities and is not universally superior. The choice depends entirely on the operational goal.

Increased Complexity and Cost

The most obvious trade-off is cost and complexity. A dual track furnace requires two complete induction units, doubling the initial capital investment and the sophisticated power electronics needed to run them.

Maintenance and Refractory Wear

The narrow channels, or "throats," are high-wear areas due to the intense heat and metal flow. A dual track design has two such areas to monitor and maintain, increasing the frequency and cost of relining the refractory materials.

Higher Energy Standby Loss

While efficient at high power, the larger surface area and two induction units can lead to higher thermal losses when the furnace is in a holding pattern (idling with molten metal). This makes it less efficient for applications requiring long holding periods at low power.

Making the Right Choice for Your Goal

The decision to use a dual track furnace is a strategic one based on production volume and operational needs.

- If your primary focus is high-volume, continuous melting: The dual track furnace is an excellent choice, as its superior power and melting rate maximize throughput.

- If your primary focus is flexibility for varied batch sizes: A standard coreless or single-channel furnace offers better cost-effectiveness and operational simplicity.

- If your primary focus is minimizing maintenance and initial cost: The simpler design of a single-unit furnace is the more prudent and reliable option.

Ultimately, selecting the right furnace configuration requires a clear understanding of your specific production demands and operational economics.

Summary Table:

| Feature | Single Track Furnace | Dual Track Furnace |

|---|---|---|

| Induction Units | 1 | 2 |

| Melting Power & Speed | Standard | Significantly Higher |

| Metal Circulation | Good | Excellent (Enhanced Homogeneity) |

| Best For | Flexible Batch Sizes | High-Volume, Continuous Melting |

| Complexity & Cost | Lower | Higher (More Maintenance & Initial Investment) |

Need to scale up your metal melting operations? A dual track induction furnace from KINTEK can dramatically increase your throughput and efficiency. Our expertise in high-performance lab and industrial equipment ensures you get the right solution for your high-volume production needs. Contact our experts today to discuss how a dual track furnace can optimize your process!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- Can Aluminium be melted in induction furnace? Yes, for Faster, Cleaner Melting

- How does a vacuum induction melting furnace affect compositional consistency? Achieve Unparalleled Metal Uniformity

- What are the major drawbacks of a direct core type induction furnace? Understand the Trade-offs for Your Foundry

- What is the use of aluminium melting furnace? Achieve High-Purity, Efficient Metal Processing

- What are the characteristics of induction furnace? High-Efficiency, Clean Melting for Superior Metal Quality

- What factors influence the quality of the sintered induction furnace lining? Optimize Durability and Performance

- What is the difference between core type furnace and coreless induction furnace? Choose the Right Tool for Your Foundry

- What are the two main types of induction furnaces? Coreless vs. Channel for Your Melting Needs