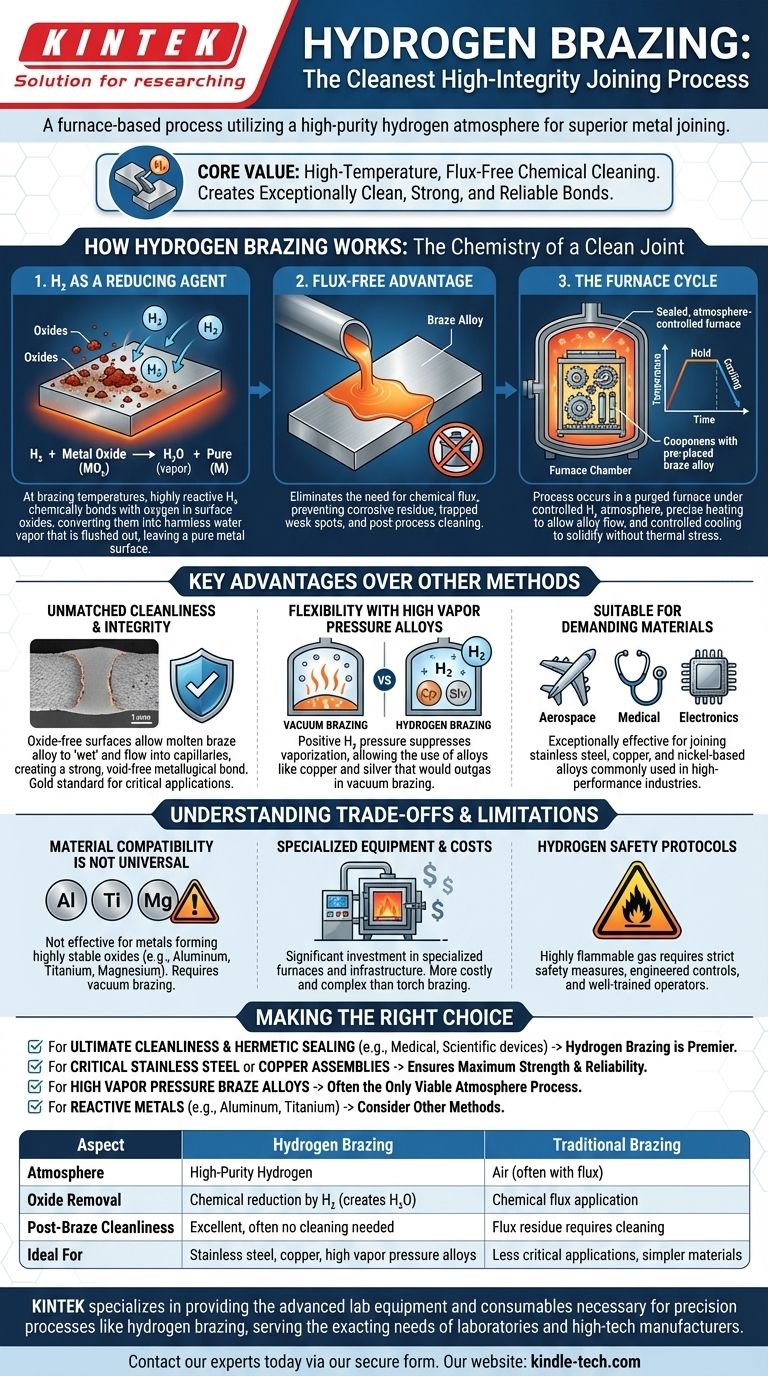

In short, hydrogen brazing is a furnace-based joining process that uses a high-purity hydrogen atmosphere to prepare metals for brazing. The hydrogen acts as a powerful cleaning agent at high temperatures, chemically removing surface oxides from the parent materials. This allows the molten braze alloy to flow freely and create an exceptionally clean, strong, and high-integrity metallurgical bond.

The core value of hydrogen brazing is not just the heat, but the atmosphere itself. It functions as a high-temperature, flux-free chemical cleaning process that produces superior joints, especially for applications demanding extreme cleanliness and reliability.

How Hydrogen Brazing Works: The Chemistry of a Clean Joint

To understand why hydrogen brazing is so effective, you must first understand its role as a chemical agent, not just an inert atmosphere.

The Role of Hydrogen as a Reducing Agent

At brazing temperatures, the hydrogen gas becomes highly reactive. It actively seeks out and bonds with oxygen atoms present in the metal oxides (like rust or tarnish) on the surface of the parts.

This chemical reaction, known as reduction, converts the solid metal oxides into harmless water vapor (H₂O), which is then flushed from the furnace. The result is a perfectly clean, pure metal surface.

Eliminating the Need for Chemical Flux

In traditional brazing, a chemical flux is applied to dissolve and displace oxides. However, flux can become trapped in the joint, causing corrosion or creating weak spots.

Hydrogen brazing completely eliminates the need for flux. The hydrogen gas performs the cleaning function, ensuring no corrosive residues are left behind. Parts emerge from the furnace bright and clean, often requiring no post-process cleaning.

The Furnace Process

The entire process takes place within a sealed, atmosphere-controlled furnace. Parts are assembled with the braze alloy pre-placed, loaded into the furnace, and the chamber is purged of air and filled with hydrogen.

The furnace then ramps to the precise brazing temperature, holds for a set time to allow the alloy to melt and flow, and then executes a controlled cooling cycle to solidify the joint without introducing thermal stress.

Key Advantages Over Other Methods

Choosing hydrogen brazing is a deliberate decision based on its unique process advantages, particularly when compared to vacuum or traditional torch brazing.

Unmatched Joint Cleanliness and Integrity

Because the hydrogen atmosphere actively removes oxides from the entire assembly, the molten braze alloy can "wet" and flow into the joint capillaries more effectively.

This produces a void-free, high-integrity joint with a strong metallurgical bond. It is the gold standard for applications where joint failure is not an option.

Flexibility with High Vapor Pressure Alloys

One of the most significant advantages over vacuum brazing is the ability to use braze alloys with high vapor pressure, such as certain copper and silver fillers.

In a vacuum, these elements would boil off (outgas) before they could effectively melt and flow. The positive pressure of the hydrogen atmosphere suppresses this vaporization, making their use possible.

Suitable for Demanding Materials

Hydrogen brazing is exceptionally effective for joining materials like stainless steel, copper, and certain nickel-based alloys. These are common in high-performance applications across aerospace, medical, and electronics industries.

Understanding the Trade-offs and Limitations

While powerful, hydrogen brazing is not a universal solution. Understanding its limitations is critical for proper application.

Material Compatibility Is Not Universal

Hydrogen is not a strong enough reducing agent for all metals. Materials that form highly stable oxides, such as aluminum, titanium, and magnesium, cannot be effectively cleaned by a hydrogen atmosphere. These materials require different methods, like vacuum brazing.

Specialized Equipment and Costs

Hydrogen brazing requires a significant investment in specialized atmosphere-controlled furnaces and associated infrastructure. This makes the process more costly and complex than simpler methods like torch brazing.

Hydrogen Safety Protocols

Hydrogen is a highly flammable gas that requires strict safety protocols, engineered controls, and well-trained operators. The operational complexity and safety management are key considerations for any facility.

Making the Right Choice for Your Application

Selecting the correct brazing process depends entirely on your material, cleanliness requirements, and performance goals.

- If your primary focus is ultimate cleanliness and hermetic sealing: Hydrogen brazing is a premier choice, especially for medical and scientific devices like X-ray tubes.

- If you are joining stainless steel or copper assemblies for critical applications: The oxide-reducing capability of hydrogen ensures maximum joint strength and reliability.

- If you must use a high vapor pressure braze alloy: Hydrogen brazing is often the only viable atmosphere-controlled process over vacuum brazing.

- If you are working with reactive metals like aluminum or titanium: You must look to other methods, such as vacuum brazing with specialized filler metals.

By weighing the unique chemical advantages against the operational requirements, you can make an informed decision for your specific engineering challenge.

Summary Table:

| Aspect | Hydrogen Brazing | Traditional Brazing |

|---|---|---|

| Atmosphere | High-Purity Hydrogen | Air (often with flux) |

| Oxide Removal | Chemical reduction by H₂ (creates H₂O) | Chemical flux application |

| Post-Braze Cleanliness | Excellent, often no cleaning needed | Flux residue requires cleaning |

| Ideal For | Stainless steel, copper, high vapor pressure alloys | Less critical applications, simpler materials |

Need a flawless, high-integrity braze for your critical components?

Hydrogen brazing is the solution for achieving exceptionally clean and strong metallurgical bonds in demanding applications. If you work with stainless steel, copper, or require the use of high vapor pressure braze alloys, our expertise and specialized furnace technology can ensure your project's success.

KINTEK specializes in providing the advanced lab equipment and consumables necessary for precision processes like hydrogen brazing, serving the exacting needs of laboratories and high-tech manufacturers.

Contact our experts today via our secure form to discuss how hydrogen brazing can elevate your product's quality and reliability.

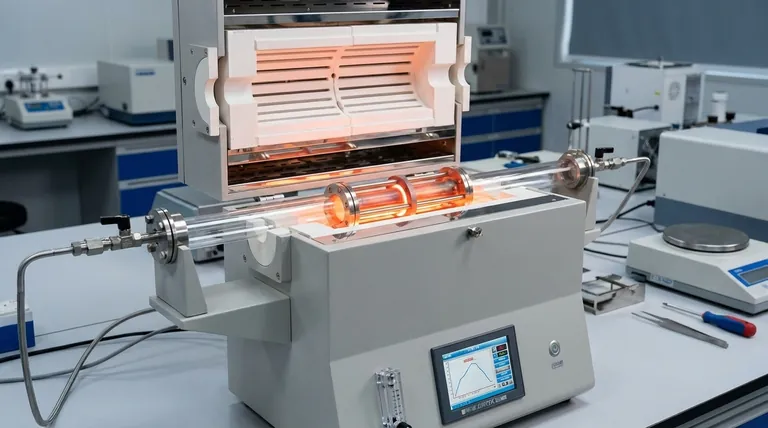

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a tubular furnace work? A Guide to Controlled High-Temperature Processing

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- What material are furnace tubes? Choosing the Right Material for High-Temperature Success

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process