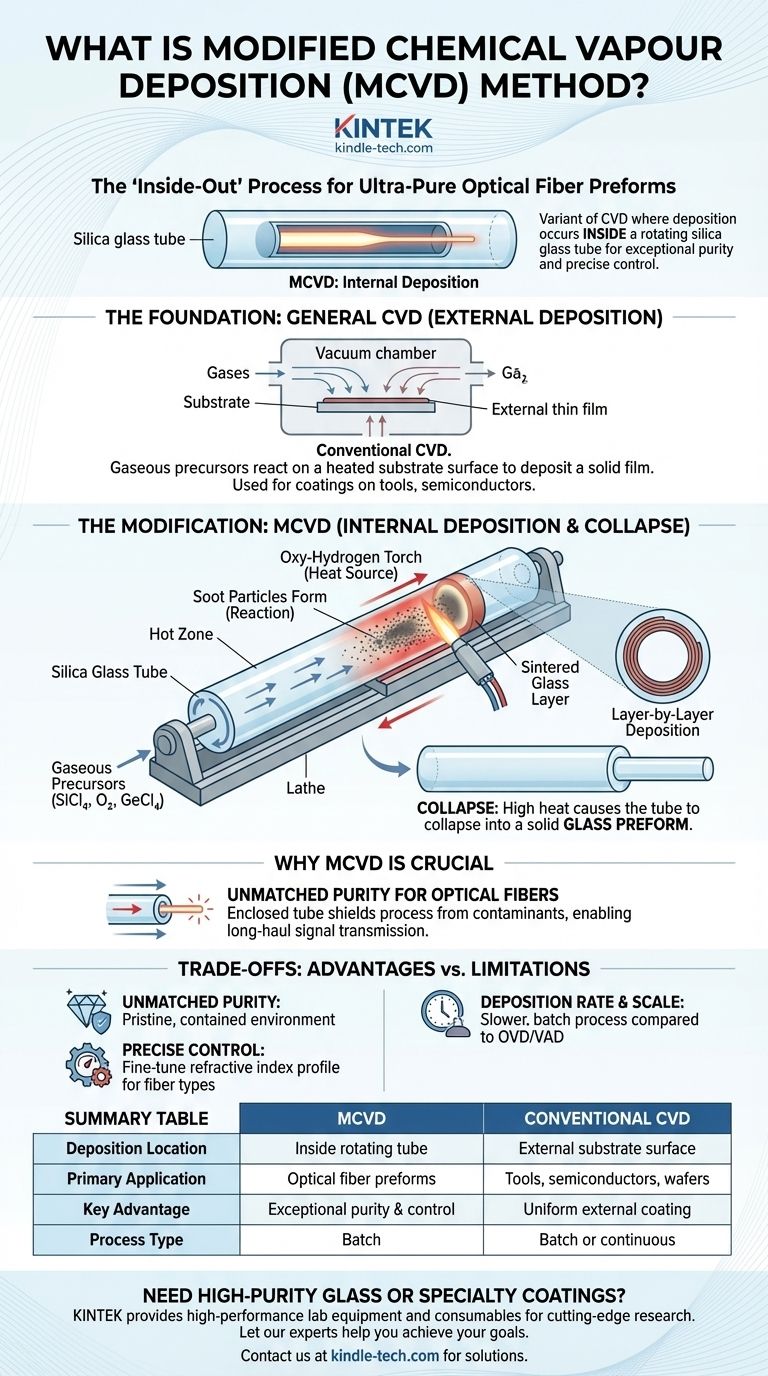

Modified Chemical Vapor Deposition (MCVD) is a highly specialized manufacturing process used to create the ultra-pure glass preforms that are drawn into optical fibers. It is a variant of Chemical Vapor Deposition (CVD) where the deposition of material occurs inside a rotating silica glass tube, rather than on an external surface. This "inside-out" approach is the key modification, allowing for exceptional purity and precise control over the material's composition, which is critical for modern telecommunications.

The core concept to grasp is that MCVD transformed manufacturing by moving the chemical reaction into a contained, pristine environment. This single change—from coating an object externally to building material internally within a tube—was the breakthrough that enabled the creation of low-loss optical fibers, forming the physical backbone of the internet.

The Foundation: Understanding General CVD

To appreciate what makes MCVD unique, we must first understand the fundamental principles of Chemical Vapor Deposition (CVD) that it is built upon.

What is Chemical Vapor Deposition?

Chemical Vapor Deposition is a process used to apply a thin, solid film onto a substrate (a workpiece). It achieves this not by spraying a liquid or melting a solid, but through a chemical reaction that occurs in a gaseous state.

The Core Mechanism

The process takes place in a reaction chamber, often under a vacuum. Gaseous chemical precursors—volatile molecules containing the atoms you want to deposit—are introduced into the chamber. The substrate is heated, and when the precursor gases come into contact with this hot surface, they react or decompose, leaving behind the desired solid material as a thin film bonded to the surface.

Common Applications

General CVD is a workhorse in many industries. It is used to deposit hard, corrosion-resistant coatings on cutting tools, grow thin films for semiconductors and electronics, and create photovoltaic layers for thin-film solar cells.

The "Modification": How MCVD Changes the Game

MCVD takes the principles of CVD and adapts them for a very specific and demanding application: fabricating the core of an optical fiber.

Shifting from External to Internal Deposition

Unlike conventional CVD which coats the outside of an object, MCVD deposits material on the inner wall of a high-purity silica tube. This tube is mounted on a lathe and rotated continuously to ensure uniformity.

The Step-by-Step MCVD Process

-

Reaction: A precise mixture of gaseous precursors, typically silicon tetrachloride (SiCl₄) and oxygen (O₂), is passed through the inside of the rotating tube. Dopants like germanium tetrachloride (GeCl₄) are added to control the refractive index.

-

Deposition: A heat source, usually an oxy-hydrogen torch, traverses the length of the tube from the outside. The intense heat creates a localized hot zone, causing the gases inside to react and form microscopic glass particles (soot).

-

Sintering: These soot particles are deposited on the inner wall of the tube just downstream of the moving hot zone. As the torch continues its pass, it heats this newly deposited soot layer, fusing or sintering it into a solid, transparent glass layer.

-

Collapse: This process is repeated dozens or even hundreds of times, building up layer after layer to create the desired core and cladding structure. Finally, the heat is increased significantly, causing the softened tube to collapse inward under surface tension into a solid glass rod known as a preform.

Why This Method is Crucial for Fiber Optics

The preform created by MCVD is a scaled-up version of the final optical fiber. The exceptional purity achieved by conducting the reaction inside a sealed tube is what allows light signals to travel for kilometers with minimal signal loss.

Understanding the Trade-offs

No process is perfect. The specific design of MCVD brings powerful advantages but also inherent limitations.

Advantage: Unmatched Purity

The enclosed tube acts as its own pristine reaction chamber, shielding the deposition process from environmental contaminants like dust or water vapor. This is the primary reason MCVD produces glass pure enough for long-haul fiber optics.

Advantage: Precise Compositional Control

By minutely adjusting the gas mixture for each pass of the torch, manufacturers can create a highly precise refractive index profile. This control is essential for engineering different types of fibers, such as single-mode or multi-mode, for specific applications.

Limitation: Deposition Rate and Scale

MCVD is a batch process and is relatively slow compared to alternative methods developed later, such as Outside Vapor Deposition (OVD) and Vapor Axial Deposition (VAD). These other methods were designed to produce larger preforms at a faster rate, but often require a separate sintering step.

Making the Right Choice for Your Goal

The choice between MCVD and other deposition methods is driven entirely by the required purity and structure of the final product.

- If your primary focus is creating ultra-pure glass for optical fibers or specialty laser components: MCVD is the benchmark technology due to its unparalleled purity and precise control over the refractive index profile.

- If your primary focus is coating a complex 3D object like a tool or a semiconductor wafer: A conventional external CVD process is the appropriate choice, as it is designed to uniformly coat external surfaces.

- If your primary focus is high-volume production of optical fiber preforms: You might investigate alternative methods like OVD or VAD, which can offer higher deposition rates for mass production.

Understanding the fundamental difference between internal and external deposition is the key to selecting the right tool for your material science objective.

Summary Table:

| Feature | MCVD | Conventional CVD |

|---|---|---|

| Deposition Location | Inside a rotating silica tube | On the external surface of a substrate |

| Primary Application | Fabricating ultra-pure optical fiber preforms | Coating tools, semiconductors, and wafers |

| Key Advantage | Exceptional purity and precise compositional control | Uniform coating of complex 3D external shapes |

| Process Type | Batch process | Can be batch or continuous |

Need to Develop High-Purity Glass or Specialty Coatings?

The precise control and unmatched purity of the MCVD process are critical for advanced materials. At KINTEK, we specialize in providing the high-performance lab equipment and consumables needed for cutting-edge research and development in fields like fiber optics and material science.

Let our experts help you achieve your goals. Contact our team today to discuss how our solutions can support your specific laboratory needs.

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What is the primary function of an industrial rotary tube furnace? Master Tungsten Powder Hydrogen Reduction

- What are the advantages and disadvantages of rotary furnace? Maximize Uniformity & Efficiency in Thermal Processing

- What is the process of zirconium production? From Ore to High-Performance Metal & Ceramic

- What reaction conditions do high-temperature tube furnaces provide for biochar reduction? Optimize Ore Processing

- Why is a high-temperature furnace with multi-probe testing used for ABO3 perovskite? Get Precise Conductivity Data