A muffle furnace is a high-temperature oven that heats materials inside a controlled chamber without direct contact from the heating elements. Its primary function is to provide a uniform, contaminant-free thermal environment, making it a critical tool in scientific laboratories and industrial settings for tasks ranging from chemical analysis to materials processing.

The core value of a muffle furnace is its ability to create an isolated, high-temperature environment. This separation prevents contamination from the heat source, ensuring the integrity of the material being heated and enabling precise, repeatable results for both material transformation and chemical analysis.

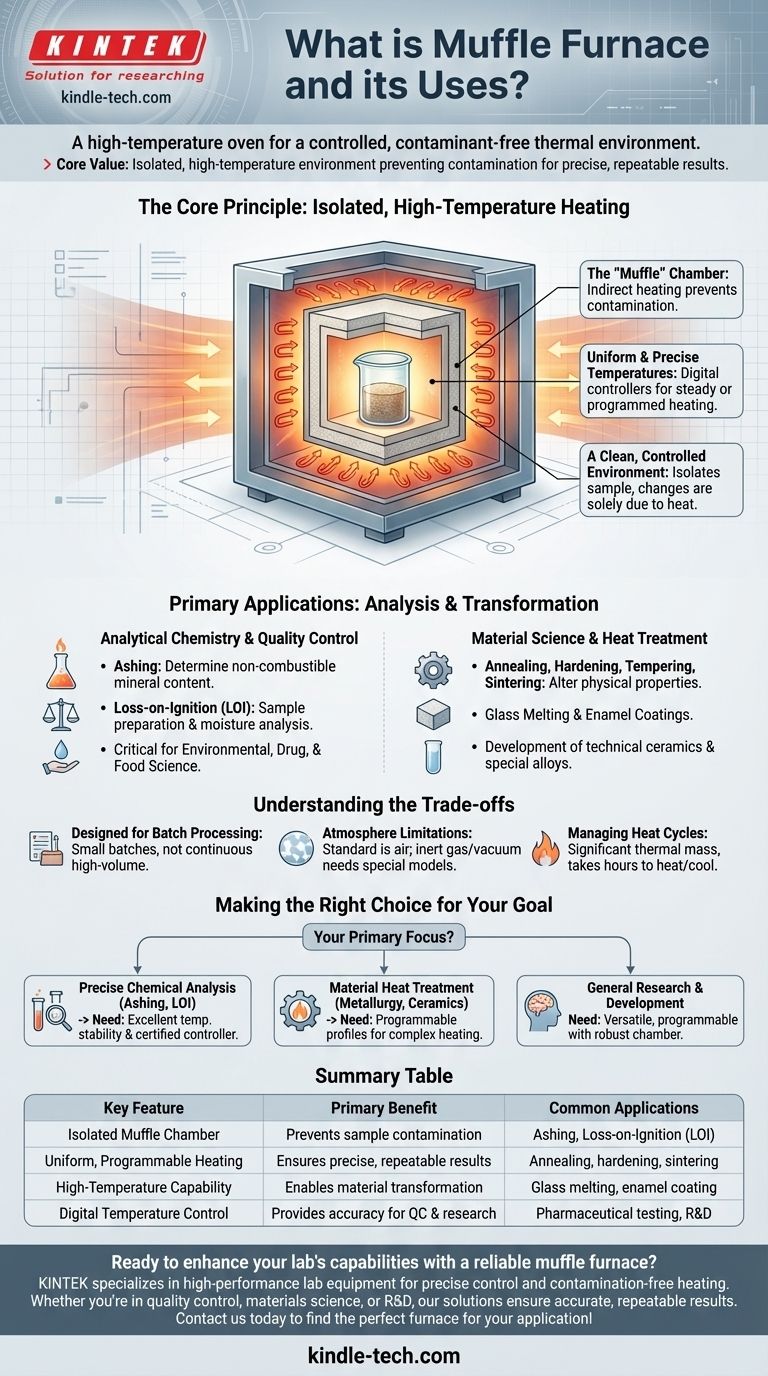

The Core Principle: Isolated, High-Temperature Heating

A muffle furnace's design is fundamental to its wide range of uses. Unlike a simple kiln or forge, its key feature is the "muffle"—an insulated inner chamber that separates the sample from the actual heating elements.

The "Muffle" Chamber

The material to be heated is placed inside the muffle, which is typically made of a high-temperature ceramic.

This chamber is then heated from the outside by electric resistance elements. This indirect heating method is what prevents contamination from combustion byproducts or direct contact with electrical components.

Uniform and Precise Temperatures

This design allows for extremely uniform heat distribution throughout the chamber. Modern furnaces use digital controllers to precisely manage temperature, holding it steady or ramping it up and down according to a programmed profile.

A Clean, Controlled Environment

By isolating the sample, the furnace ensures that any changes observed—such as weight loss during ashing or a change in material properties during annealing—are solely due to the effects of heat, not a chemical reaction with the heat source.

Primary Applications: From Analysis to Transformation

The uses of a muffle furnace are vast but can be grouped into two main categories: analyzing what a material is made of and changing what a material is.

Analytical Chemistry and Quality Control

The furnace is a cornerstone of analytical labs for determining a material's composition.

Common uses include ashing, where a sample is burned at a high temperature to determine its non-combustible mineral content. It is also used for loss-on-ignition (LOI) analysis and determining moisture or volatile content.

These processes are critical for sample preparation in environmental analysis, drug testing, and food science.

Material Science and Heat Treatment

In metallurgy and materials science, the furnace is used to alter the physical properties of materials.

This includes processes like annealing (to soften metal), hardening (to increase strength), tempering (to reduce brittleness), and sintering (to fuse ceramic or metal powders into a solid).

It is also used for creating enamel coatings on metal, melting glass, and developing technical ceramics and special alloys.

Understanding the Trade-offs

While incredibly versatile, muffle furnaces have operational considerations that define their ideal use cases.

Designed for Batch Processing

Most muffle furnaces are designed for processing individual items or small batches of samples. They are generally not suited for continuous, high-volume industrial production lines.

Atmosphere Limitations

A standard muffle furnace operates with a normal air atmosphere inside the chamber. While this is suitable for most applications, processes that require an inert gas (like argon) or a vacuum to prevent oxidation require more specialized and costly furnace models.

Managing Heat Cycles

Due to their significant thermal mass, these furnaces do not heat or cool instantly. A full thermal cycle can take several hours, which must be factored into any laboratory or production workflow.

Making the Right Choice for Your Goal

To leverage a muffle furnace effectively, align its capabilities with your specific objective.

- If your primary focus is precise chemical analysis (ashing, LOI): You need a furnace with excellent temperature stability and a certified controller to ensure your results are accurate and repeatable.

- If your primary focus is material heat treatment (metallurgy, ceramics): Your priority is a furnace with programmable temperature profiles that can execute complex heating and cooling ramps reliably.

- If your primary focus is general research and development: A versatile, programmable furnace with a robust chamber is essential to accommodate a wide range of sample types and experimental protocols.

Ultimately, the muffle furnace is a foundational tool for any process that demands pure, controlled, high-temperature heating.

Summary Table:

| Key Feature | Primary Benefit | Common Applications |

|---|---|---|

| Isolated Muffle Chamber | Prevents sample contamination from heating elements | Ashing, Loss-on-Ignition (LOI) analysis |

| Uniform, Programmable Heating | Ensures precise, repeatable results | Annealing, hardening, sintering of metals & ceramics |

| High-Temperature Capability | Enables material transformation & analysis | Glass melting, enamel coating, sample preparation |

| Digital Temperature Control | Provides accuracy for quality control & research | Pharmaceutical testing, environmental analysis, R&D |

Ready to enhance your lab's capabilities with a reliable muffle furnace? KINTEK specializes in high-performance lab equipment, including muffle furnaces designed for precise temperature control and contamination-free heating. Whether you're in quality control, materials science, or research and development, our solutions ensure accurate, repeatable results. Contact us today to find the perfect furnace for your specific application!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How do the properties of materials change with the heat treatment? Tailor Hardness, Strength, and Ductility

- What are the classification of refractory materials? A Guide to Chemical and Thermal Selection

- What is the difference between a lab furnace and a lab oven? Choose the Right Heating Tool for Your Lab

- Why does melting require energy? Unlock the Science of Latent Heat and Phase Changes

- How do you adjust the temperature on a muffle furnace? Master Precise Control for Your Lab