In short, PVD coating is a modern process used to produce a highly durable, long-lasting finish on jewelry. Standing for Physical Vapor Deposition, this high-tech vacuum process molecularly bonds the coating to the base metal, creating a surface that is significantly more resistant to scratches, fading, and corrosion than traditional plating methods.

At its core, PVD is not just a layer of color placed on top of jewelry; it is an advanced finishing process that integrates a protective, decorative film into the surface of the item itself, creating superior durability and aesthetic longevity.

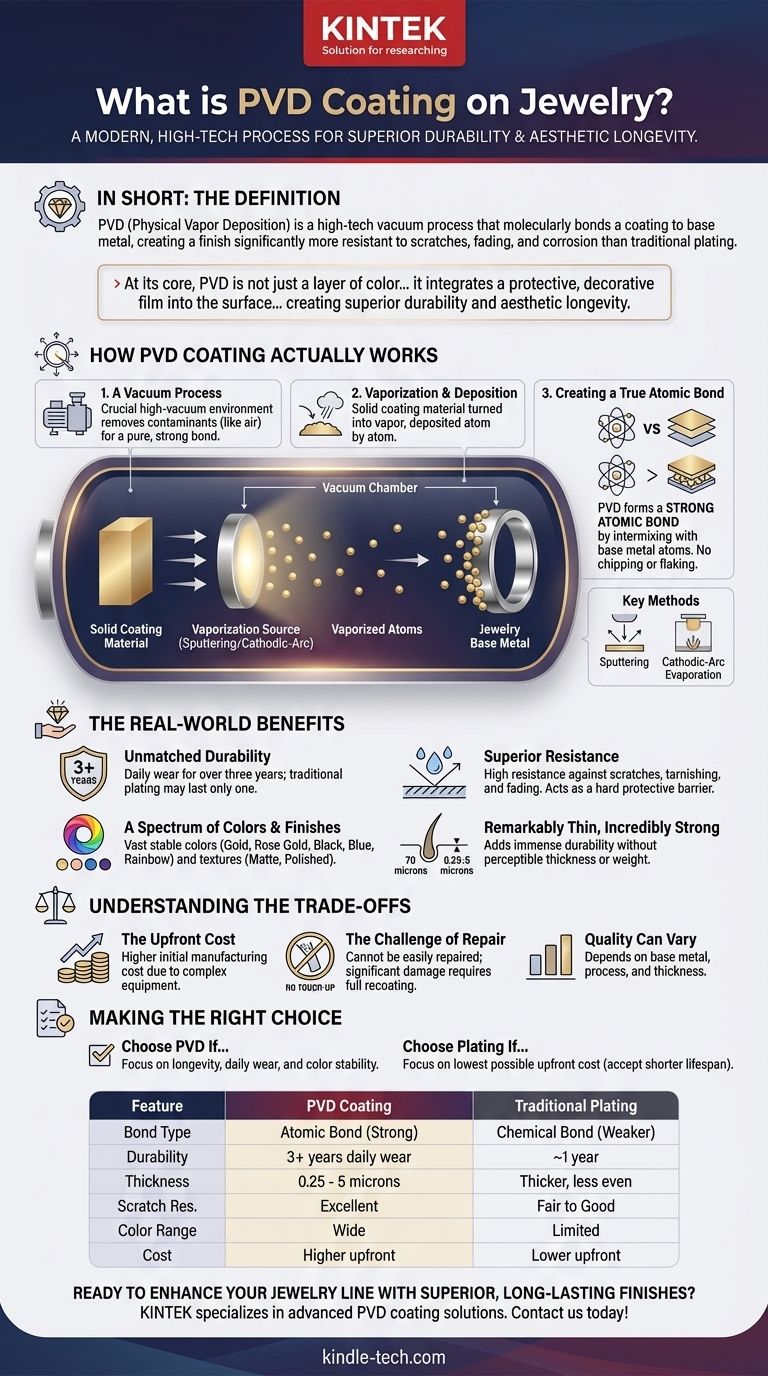

How PVD Coating Actually Works

The term "Physical Vapor Deposition" sounds complex, but the underlying principle is straightforward. It involves turning a solid coating material into a vapor and then depositing it, atom by atom, onto the surface of the jewelry inside a vacuum chamber.

The Core Principle: A Vacuum Process

The entire PVD process must happen in a high-vacuum environment. This is critical because it removes other atoms (like air) that could contaminate the coating or interfere with the process, ensuring a pure and strong bond.

Creating a True Atomic Bond

Unlike electroplating, which creates a weaker chemical bond, PVD forms a strong atomic bond. The vaporized coating material intermixes with the surface atoms of the jewelry's base metal (often stainless steel). This is why PVD coatings don't chip, flake, or peel off easily.

Key PVD Methods for Jewelry

Two primary techniques are used for jewelry: Sputtering Evaporation and Cathodic-Arc Evaporation. While the methods differ in how they vaporize the coating material, both result in a thin, dense, and tightly bonded film on the final product.

The Real-World Benefits of PVD

Understanding the process helps explain why PVD-coated jewelry has become a standard for quality. The benefits are tangible and directly impact the owner's experience.

Unmatched Durability and Longevity

The strong atomic bond makes PVD finishes extremely tough. Jewelry with a PVD coating can be worn daily for over three years without showing significant wear, whereas traditional electroplated items may last only one year.

Superior Resistance to Wear and Tear

This durability translates directly to a high resistance against scratches, tarnishing, and fading. The coating acts as a hard protective barrier that keeps the jewelry looking brilliant for an extended period.

A Spectrum of Colors and Finishes

PVD allows for a vast range of stable colors, including gold, rose gold, black, blue, coffee, and even rainbow effects. It can also produce different surface textures, such as matte or highly polished finishes, offering significant aesthetic versatility.

Remarkably Thin, Incredibly Strong

A typical PVD coating on jewelry is only 0.25 to 5 microns thick. For perspective, a human hair is about 70 microns in diameter. This process adds immense durability without adding any perceptible thickness or weight to the piece.

Understanding the Trade-offs

While PVD technology is superior in many ways, it's important to have a balanced perspective. No single process is perfect for every application.

The Upfront Cost

PVD requires sophisticated, expensive equipment and is a more complex process than traditional electroplating. This often results in a higher initial manufacturing cost, which can be reflected in the retail price of the jewelry.

The Challenge of Repair

Because the coating is atomically bonded to the surface, it cannot be easily "touched up" if a deep scratch does occur. Repairing significant damage would likely require the entire piece to be stripped and professionally recoated, which is often impractical.

Quality Can Vary

The final quality of a PVD coating depends on several factors: the quality of the base metal, the specific PVD process used, and the thickness of the applied coating. A very thin or poorly applied coating will not offer the same longevity as a high-quality one.

Making the Right Choice for Your Goal

Ultimately, the decision to choose PVD-coated jewelry depends on your priorities.

- If your primary focus is longevity and daily wear: PVD is the definitive choice for its superior resistance to scratches, sweat, and tarnishing.

- If your primary focus is aesthetic variety and color stability: PVD offers a wide range of vibrant, long-lasting colors that won't fade over time.

- If your primary focus is the lowest possible upfront cost: Traditional plating may be cheaper, but you must accept it will require more care and have a significantly shorter lifespan.

By choosing PVD, you are investing in a piece of jewelry engineered for durability and lasting beauty.

Summary Table:

| Feature | PVD Coating | Traditional Plating |

|---|---|---|

| Bond Type | Atomic Bond | Chemical Bond |

| Durability | 3+ years daily wear | ~1 year |

| Thickness | 0.25 - 5 microns | Thicker, less even |

| Scratch Resistance | Excellent | Fair to Good |

| Color Range | Wide (Gold, Black, Rose Gold, etc.) | Limited |

| Cost | Higher upfront | Lower upfront |

Ready to enhance your jewelry line with superior, long-lasting finishes? KINTEK specializes in advanced PVD coating solutions for jewelry manufacturers. Our expertise ensures your products achieve unmatched durability and vibrant, fade-resistant colors that customers love.

Contact us today to discuss how our PVD coating services can add value and longevity to your jewelry collections!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is plasma enhanced chemical vapour deposition process? Unlock Low-Temperature, High-Quality Thin Films

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films

- What is PECVD silicon deposition? Achieve Low-Temperature, High-Quality Thin Films