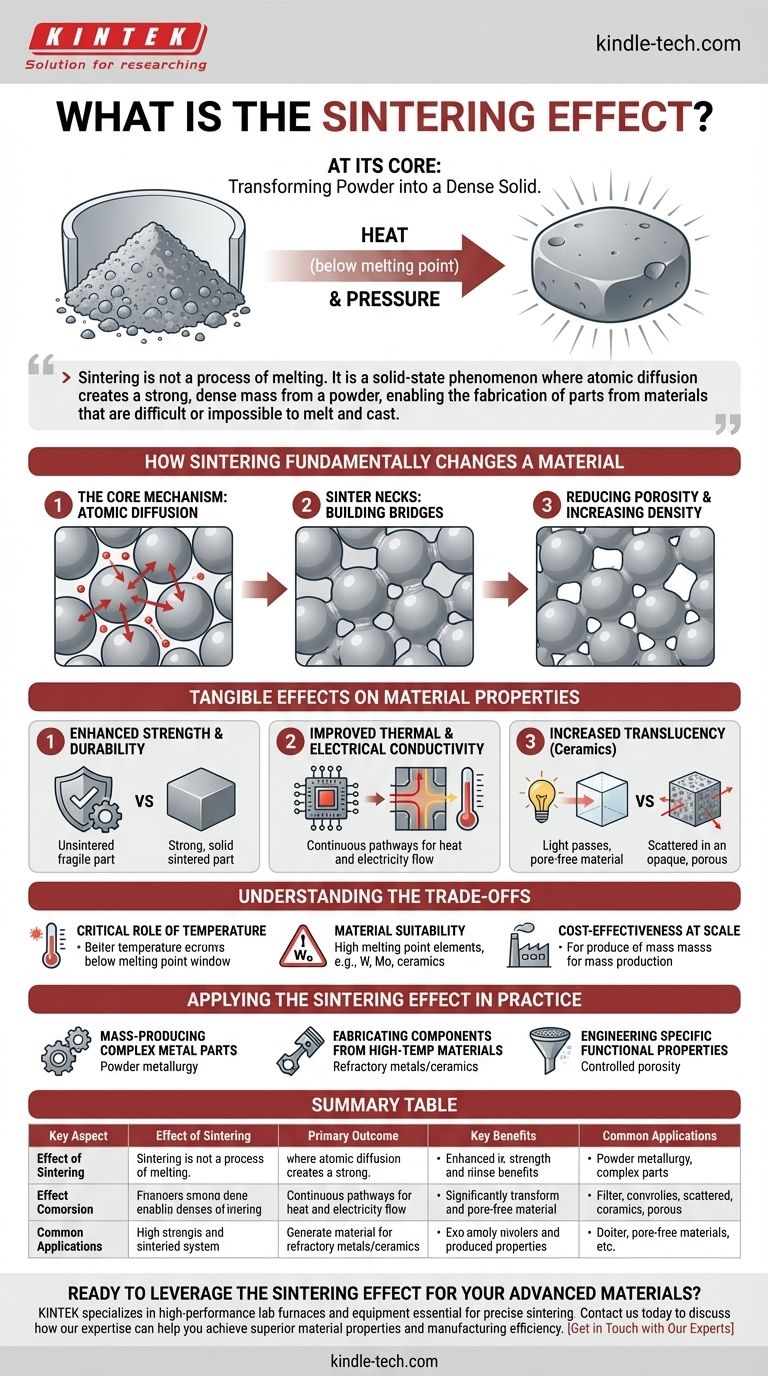

At its core, the sintering effect is the transformation of a collection of individual powder particles into a single, solid, and dense object. This is achieved by applying heat and sometimes pressure at a temperature below the material's melting point, causing the atoms to fuse the particles together, dramatically increasing the material's strength and integrity while reducing internal voids.

Sintering is not a process of melting. It is a solid-state phenomenon where atomic diffusion creates a strong, dense mass from a powder, enabling the fabrication of parts from materials that are difficult or impossible to melt and cast.

How Sintering Fundamentally Changes a Material

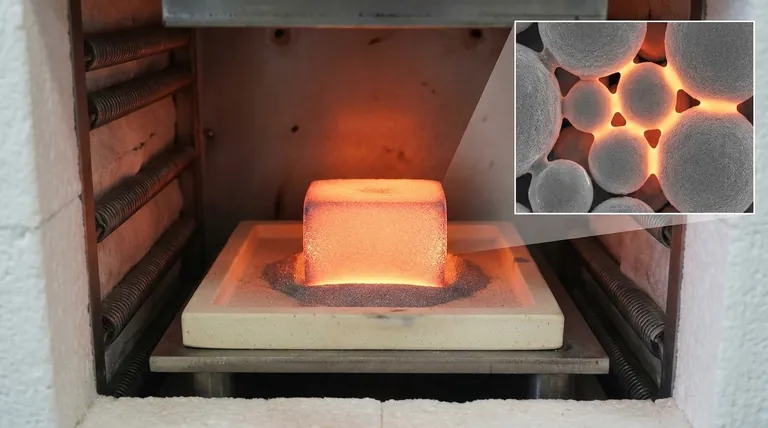

The sintering effect is a direct result of changes happening at the microscopic level. Understanding this mechanism is key to appreciating its impact on the final product.

The Core Mechanism: Atomic Diffusion

Sintering works because atoms in the solid particles are not static. When heated, they gain energy and begin to migrate across the boundaries where particles touch.

This atomic movement effectively builds bridges, or "sinter necks," between adjacent particles. These bridges grow over time, fusing the individual grains into a continuous, interconnected network.

Reducing Porosity and Increasing Density

A container of powder is mostly empty space, or porosity. As the sinter necks form and grow, they pull the particles closer together.

This process systematically shrinks and eliminates the voids between the particles. The direct result is a significant increase in the overall density of the material.

Developing Structural Strength

An unsintered, compacted powder (often called a "green body") is fragile and can crumble easily. The sintering effect is what gives the part its final strength and durability.

By fusing the particles into a solid piece, the process creates a robust structure capable of withstanding mechanical stress.

The Tangible Effects on Material Properties

The microscopic changes from sintering produce powerful and desirable macroscopic effects, making it a critical manufacturing process for advanced materials.

Enhanced Strength and Durability

This is the primary goal of sintering. By eliminating porosity and creating a unified solid mass, the resulting part is substantially stronger and more resistant to fracture than its pre-sintered form.

Improved Thermal and Electrical Conductivity

Air gaps and voids within a material are excellent insulators. By removing this porosity, sintering creates a more direct and continuous path for heat and electricity to travel.

This makes sintered parts highly effective in applications requiring efficient thermal management or electrical performance.

Increased Translucency

In ceramic materials, internal pores are the primary reason they appear opaque. These voids scatter light in all directions.

By eliminating these pores, sintering allows light to pass through the material with less interference, resulting in a more translucent or even transparent final product.

Understanding the Trade-offs

While powerful, the sintering effect is not a universal solution. Its application is specific and requires careful control.

The Critical Role of Temperature

Sintering operates in a precise temperature window below the melting point.

Too little heat results in weak bonds and a fragile part. Too much heat can cause unwanted grain growth, distortion, or partial melting, which can degrade the final properties of the material.

Material Suitability

The process is most valuable for materials with extremely high melting points, such as tungsten, molybdenum, and many advanced ceramics.

For these materials, melting and casting is often impractical or impossible, making sintering the primary method for forming dense, durable components.

Cost-Effectiveness at Scale

Setting up a sintering process can be a significant investment. However, for mass production of small, complex parts, it becomes extremely cost-effective.

It allows for the creation of intricate, "non-machinable" geometries with high repeatability, eliminating the need for costly secondary finishing operations.

Applying the Sintering Effect in Practice

Choosing to leverage sintering depends entirely on your material and manufacturing goals.

- If your primary focus is mass-producing complex metal parts: Sintering (powder metallurgy) is an ideal method for creating highly accurate and repeatable net-shape parts at a low cost per unit.

- If your primary focus is fabricating components from high-temperature materials: Sintering is often the only viable process to form strong, dense parts from ceramics or refractory metals like tungsten.

- If your primary focus is engineering specific functional properties: Sintering allows for precise control over final density, making it perfect for creating filters, catalysts, or self-lubricating bearings with controlled porosity.

Ultimately, the sintering effect is a fundamental tool for engineering advanced materials from the particle level upward to achieve properties that are otherwise unattainable.

Summary Table:

| Key Aspect | Effect of Sintering |

|---|---|

| Process | Fuses powder particles using heat (below melting point) |

| Primary Outcome | Creates a solid, dense mass from a powder |

| Key Benefits | Increased strength, reduced porosity, improved thermal/electrical conductivity |

| Common Applications | Powder metallurgy parts, advanced ceramics, refractory metals |

Ready to leverage the sintering effect for your advanced materials?

KINTEK specializes in providing the high-performance lab furnaces and equipment essential for precise and effective sintering processes. Whether you are developing new ceramic components, manufacturing complex metal parts via powder metallurgy, or working with refractory metals, our solutions deliver the precise temperature control and uniformity critical for success.

Contact us today to discuss how our expertise can help you achieve superior material properties and manufacturing efficiency.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What are the waste products of biomass? Uncover Byproducts from Ash to Biochar

- Why is argon used as a plasma gas? The Ideal Balance for Efficient Sputtering

- What is the difference between thermal decomposition and pyrolysis? A Guide to Controlled Heat Processes

- What is the minimum coating thickness? How Steel Thickness Determines Your Galvanizing Needs

- What is the principle of DC magnetron sputtering? Achieve Fast, High-Quality Thin Film Deposition

- How does a constant temperature incubator shaker facilitate the enzymatic hydrolysis of lignocellulosic materials?

- How does a high-speed homogenizer prepare m-BN and PNF dispersions? Achieve Uniform Molecular-Level Integration

- Why is energy consumption a critical consideration for ULT freezers? Key to Balancing Performance, Cost, and Sustainability