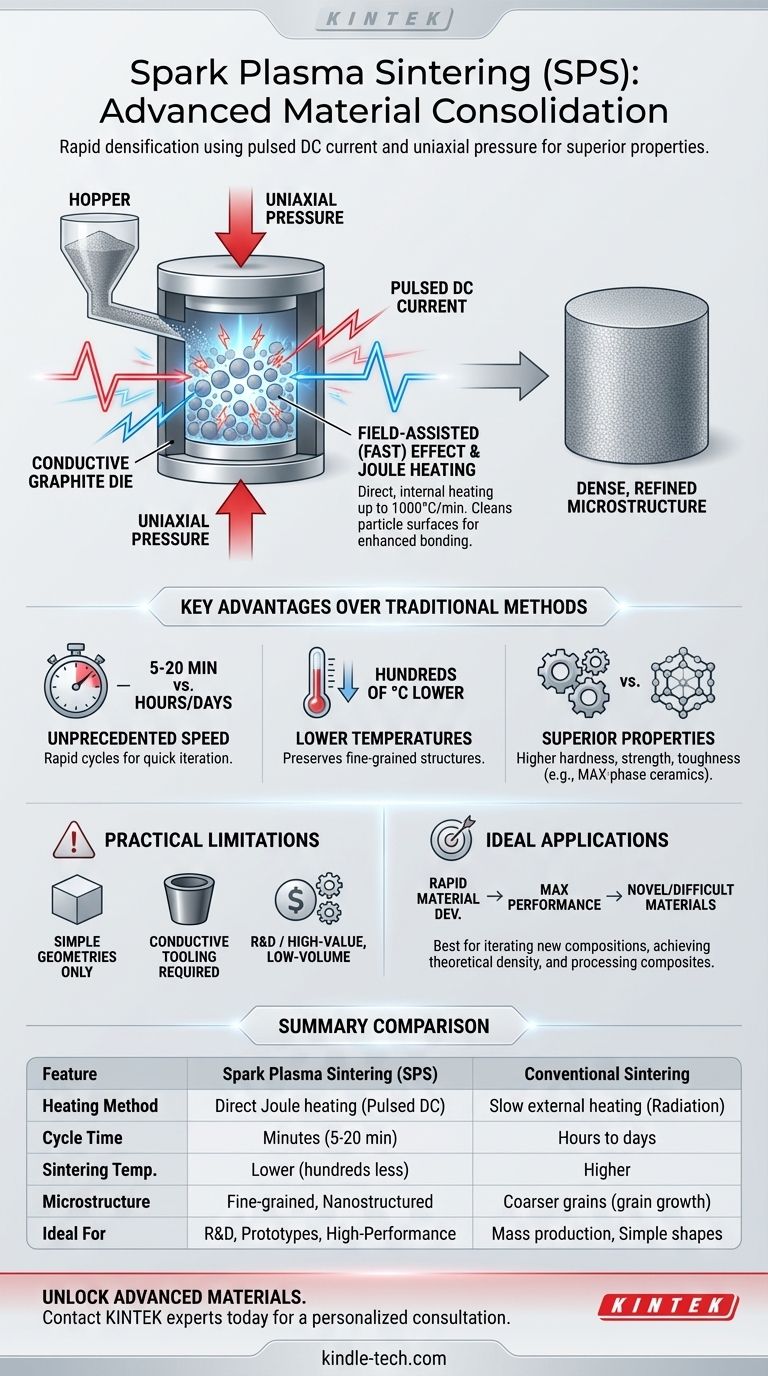

In essence, Spark Plasma Sintering (SPS) is an advanced manufacturing technique that consolidates powders into a dense, solid mass using a combination of high-amperage, pulsed direct electrical current and uniaxial pressure. Unlike conventional sintering which relies on slow, external heating in a furnace, SPS heats the material and its tooling directly and rapidly, drastically reducing the time and temperature needed to achieve full density.

The critical takeaway is that Spark Plasma Sintering is not merely a faster way to heat material. It is a field-assisted process where the electrical current actively promotes densification, enabling the creation of advanced materials with refined microstructures and superior properties that are often unattainable with traditional methods.

How SPS Redefines the Sintering Process

Traditional sintering slowly heats loose powder until the particles begin to fuse. SPS revolutionizes this by introducing an electric field directly into the equation, fundamentally changing the physics of densification.

The Core Mechanism: Joule Heating

The primary heating mechanism in SPS is Joule heating. A powerful DC current is passed through the conductive die (typically graphite) and, if the material is conductive, through the powder sample itself.

This direct, internal heat generation is incredibly efficient, enabling heating rates of up to 1000°C/min. This contrasts sharply with conventional furnaces that heat externally through radiation and convection.

Unifying Pressure and Current

Simultaneously with the electrical current, a uniaxial mechanical pressure is applied via punches. This pressure forces the powder particles into close contact, which aids both electrical conductivity between particles and the final densification process.

This simultaneous action of heat and pressure is similar to hot pressing, but the speed and electrical effects of SPS set it apart.

The "Field-Assisted" Advantage

The name "Spark Plasma Sintering" is somewhat debated, as the existence of a sustained plasma is not universally confirmed. A more accurate term is Field-Assisted Sintering Technique (FAST).

The electric field is thought to generate microscopic electrical discharges between powder particles. This can clean particle surfaces of oxides and contaminants, enhancing atomic diffusion and accelerating the bonding process far beyond what heat and pressure alone could achieve.

Key Advantages Over Traditional Methods

The unique mechanism of SPS translates into significant, tangible benefits for materials science and engineering.

Unprecedented Processing Speed

The most dramatic advantage is speed. A sintering cycle that might take many hours or even days in a conventional furnace can often be completed in 5 to 20 minutes using SPS.

Lower Sintering Temperatures

SPS consistently achieves full densification at temperatures hundreds of degrees lower than conventional techniques. This is a direct result of the electrical field activating the sintering process.

Superior Material Properties

The combination of high speed and low temperature is critical for preserving fine-grained or nanostructured microstructures. Preventing grain growth results in materials with higher hardness, fracture toughness, and strength.

For example, SPS can produce glass with enhanced optical and mechanical properties or fully dense, single-phase MAX-phase ceramics from elemental powders.

Understanding the Practical Limitations

While powerful, SPS is not a universal solution. Its operational principles introduce specific trade-offs that are critical to understand.

Geometry and Size Constraints

The process requires a rigid, typically cylindrical die and punch setup. This fundamentally limits the final parts to simple geometries and imposes practical constraints on the maximum size.

Conductive Tooling Requirement

The process relies on a conductive graphite die to transmit both current and pressure. Graphite has its own temperature limitations and can react with certain materials, which must be considered during process design.

Cost and Scalability

SPS equipment is more complex and expensive than conventional furnaces. It is best suited for research and development, rapid prototyping, and the production of high-value, low-volume components rather than mass manufacturing.

Is SPS the Right Choice for Your Application?

Deciding to use SPS depends entirely on your primary objective.

- If your primary focus is rapid material development: SPS is an unparalleled tool for quickly iterating and testing new compositions due to its incredibly short cycle times.

- If your primary focus is achieving maximum performance: SPS is the leading choice for creating materials with ultra-fine grain structures and reaching theoretical maximum density, which directly translates to superior mechanical properties.

- If your primary focus is processing novel or difficult materials: For composites, refractory materials, or advanced ceramics that are challenging to densify conventionally, SPS provides a more effective and efficient pathway.

Ultimately, Spark Plasma Sintering offers a level of control over the material consolidation process that opens new possibilities for material design and performance.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Conventional Sintering |

|---|---|---|

| Heating Method | Direct Joule heating with pulsed DC current | Slow external heating (radiation/convection) |

| Cycle Time | Minutes (5-20 min typical) | Hours to days |

| Sintering Temperature | Lower (hundreds of °C less) | Higher |

| Final Microstructure | Fine-grained, nanostructured | Coarser grains (grain growth) |

| Ideal For | R&D, prototypes, high-performance materials | Mass production, simpler geometries |

Ready to unlock the potential of advanced materials in your lab?

Spark Plasma Sintering from KINTEK can accelerate your research and development, enabling you to create materials with superior properties, finer microstructures, and unprecedented performance. Whether you're working on advanced ceramics, composites, or novel alloys, our SPS solutions are designed for precision and speed.

Let's discuss how SPS can transform your material science projects. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What are the advantages of using an SPS furnace for Ti-Nb-Zr-O scaffolds? Optimize Your Orthopedic Implants

- How hot isostatic pressing works? Achieve 100% Density in Your High-Performance Components

- What is the process of hot isostatic pressing? Achieve Maximum Density and Reliability

- What are the advantages of using Vacuum Hot Pressing Sintering Furnaces? Superior Microstructure in HEA Production

- How does a vacuum hot-press sintering furnace enhance WC/Cu material density? Achieving Superior Structural Integrity

- What is the difference between hot pressing and cold pressing in metallurgy? Choose the Right Process for Your Part

- Why is the use of a vacuum hot pressing furnace essential for CrFeMoNbZr targets? Ensure Full Density & Chemical Purity

- What is the function of vacuum sintering or hot pressing equipment? Optimize FeCrAl Alloy Densification & Strength