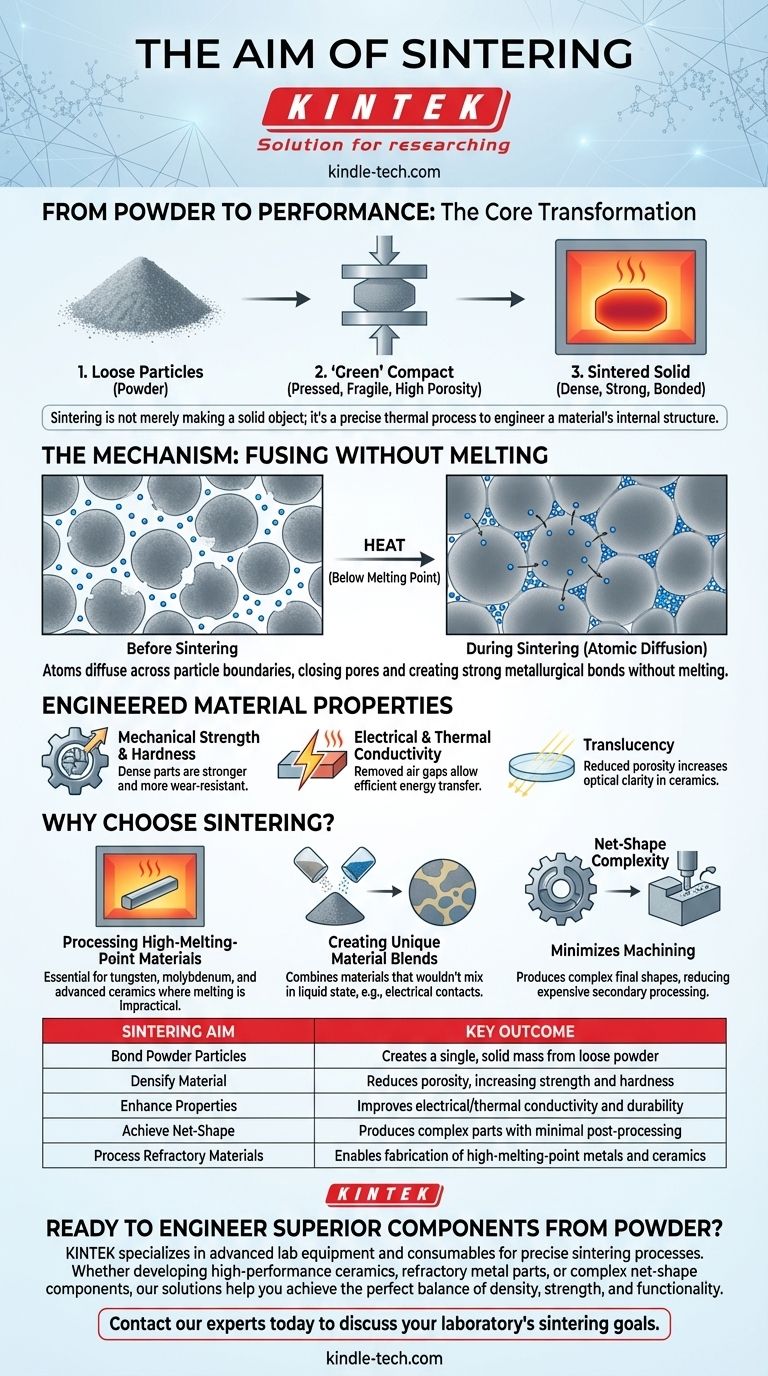

The fundamental aim of sintering is to transform a collection of loose particles or a compacted powder shape into a single, solid mass. This is achieved by applying heat below the material's melting point, causing the particles to bond together and densify, which in turn enhances the material's mechanical and physical properties.

Sintering is not merely about making a solid object; it is a precise thermal process designed to engineer a material's internal structure, removing porosity to significantly improve its strength, density, and conductivity.

From Powder to Performance: The Core Transformation

Sintering is a critical step in powder metallurgy and ceramics manufacturing. The process turns a fragile, pre-formed part into a durable, functional component.

The Starting Point: The 'Green' Compact

Before sintering can occur, a material must be prepared. This usually involves pressing a fine powder into a desired shape using a die.

This initial form is known as a "green" compact. While it holds its shape, it is mechanically weak and has high porosity—essentially, it's just compressed powder. This stage is vital for creating complex parts with tight tolerances before the final hardening.

The Mechanism: Fusing Without Melting

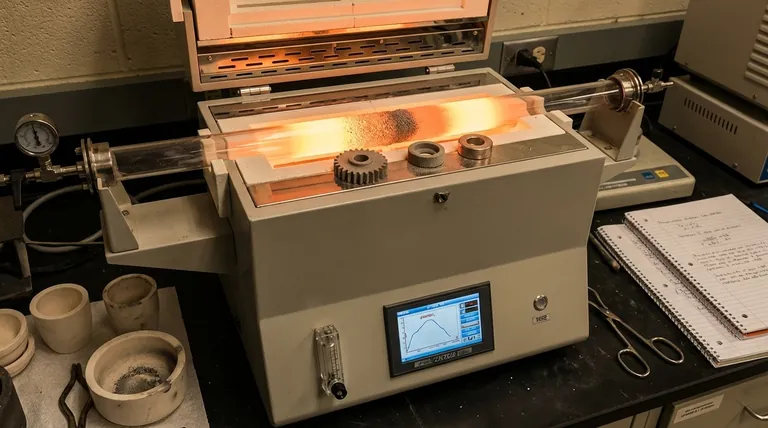

The green compact is placed in a furnace and heated to a temperature high enough to energize the atoms but low enough to avoid melting.

At this temperature, atoms begin to diffuse across the boundaries of adjacent particles. This atomic movement closes the gaps (or pores) between particles, creating strong metallurgical bonds and causing the entire part to shrink and become more dense.

The Result: Engineered Material Properties

The primary goal of this transformation is to achieve specific, desirable material characteristics.

By eliminating the internal pores, sintering drastically improves a material’s:

- Mechanical Strength and Hardness: A dense part is stronger and more resistant to wear.

- Electrical and Thermal Conductivity: Removing air gaps allows electricity and heat to travel through the material more efficiently.

- Translucency: In ceramics, reducing porosity can increase optical clarity.

Why Choose Sintering Over Melting?

While casting (melting and pouring) is a common manufacturing method, sintering offers unique advantages that make it the superior or only choice for certain applications.

Processing High-Melting-Point Materials

Sintering is essential for materials like tungsten, molybdenum, and many advanced ceramics. Their melting points are so high that melting and casting them is commercially impractical or technologically prohibitive.

Creating Unique Material Blends

The process allows for the creation of composites from materials that would not mix in a liquid state. For example, it's used to produce electrical contacts by combining copper (for conductivity) and tungsten (for arc resistance).

Achieving Net-Shape Complexity

Because the initial shape is formed by pressing powder, sintering can produce complex components like gears, cams, and structural brackets to their final (or "net") shape. This drastically reduces the need for expensive and wasteful secondary machining.

Understanding the Trade-offs

Sintering is a powerful technique, but it comes with inherent technical challenges that must be managed.

Inherent Porosity

While the goal is often full densification, achieving 100% density is difficult. Most sintered parts retain a small amount of residual porosity, which can act as a stress concentration point and may limit the material's ultimate fatigue strength compared to a fully wrought component.

Controlling Shrinkage

As the part densifies, it shrinks. This shrinkage must be precisely calculated and accounted for in the initial design of the "green" compact's tooling to ensure the final part meets dimensional specifications.

Energy and Equipment Demands

Conventional sintering requires high-temperature furnaces that consume significant energy. While often cost-effective at scale, the initial capital investment for presses and furnaces is substantial. Innovations like Cold Sintering aim to reduce these energy demands by enabling densification at much lower temperatures.

Making the Right Choice for Your Goal

Selecting sintering is a strategic decision based on your material and design requirements.

- If your primary focus is manufacturing complex metal parts at scale: Use sintering for its net-shape capabilities to reduce machining waste and enable high-volume production of components like gears and pulleys.

- If your primary focus is creating high-performance ceramic components: Sintering is the essential method for consolidating ceramic powders into a dense, strong, and functional form for thermal or electrical applications.

- If your primary focus is working with materials with extreme melting points: Sintering provides the only practical pathway to consolidate refractory metals and their alloys into solid, usable parts.

Ultimately, sintering empowers you to engineer a material from the particle level up, giving you precise control over the final product's form, density, and function.

Summary Table:

| Sintering Aim | Key Outcome |

|---|---|

| Bond Powder Particles | Creates a single, solid mass from loose powder |

| Densify Material | Reduces porosity, increasing strength and hardness |

| Enhance Properties | Improves electrical/thermal conductivity and durability |

| Achieve Net-Shape | Produces complex parts with minimal post-processing |

| Process Refractory Materials | Enables fabrication of high-melting-point metals and ceramics |

Ready to engineer superior components from powder?

KINTEK specializes in providing the advanced lab equipment and consumables necessary for precise sintering processes. Whether you are developing high-performance ceramics, refractory metal parts, or complex net-shape components, our solutions help you achieve the perfect balance of density, strength, and functionality.

Contact our experts today to discuss how we can support your laboratory's sintering and materials development goals.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance