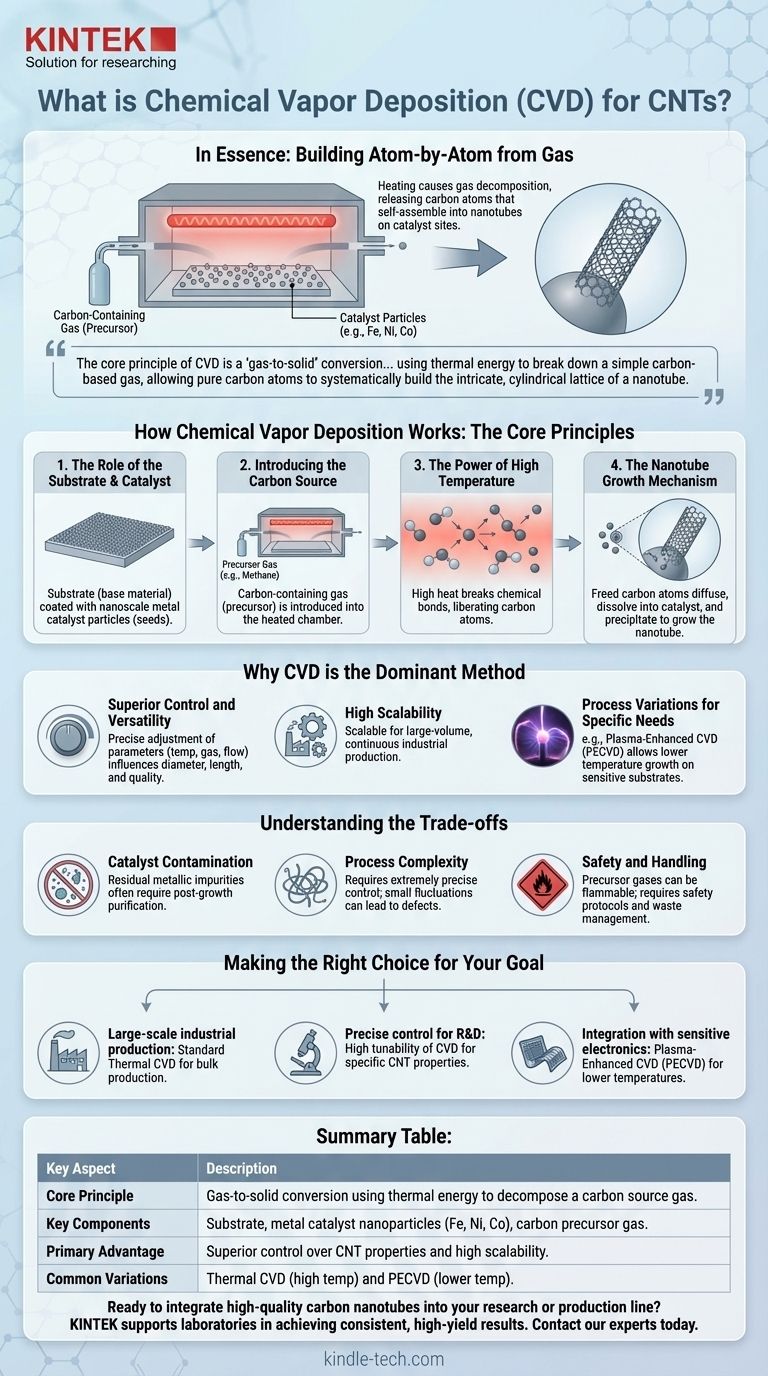

In essence, Chemical Vapor Deposition (CVD) is a method for building carbon nanotubes (CNTs) atom-by-atom from a gas. It involves heating a surface coated with catalyst particles inside a chamber and then introducing a carbon-containing gas. The high temperature causes the gas to decompose, releasing carbon atoms that then self-assemble into nanotube structures on the catalyst sites.

The core principle of CVD is a "gas-to-solid" conversion. For carbon nanotubes, this means using thermal energy to break down a simple carbon-based gas, allowing pure carbon atoms to systematically build the intricate, cylindrical lattice of a nanotube on a prepared surface.

How Chemical Vapor Deposition Works: The Core Principles

To truly understand CVD, we must look at it as a controlled, multi-step process. Each step is critical for synthesizing high-quality nanotubes with specific properties.

The Role of the Substrate and Catalyst

The entire process begins with a base material, known as a substrate. This is the surface upon which the nanotubes will grow.

Crucially, for CNT growth, this substrate is coated with a thin layer of nanoscale catalyst particles, typically metals like iron, nickel, or cobalt. These particles are the actual "seeds" from which each nanotube originates and grows.

Introducing the Carbon Source

Once the substrate is heated to the target temperature inside a reaction chamber, a carbon-containing gas (known as a precursor) is introduced.

Common precursor gases include methane, ethylene, or acetylene. The choice of gas is a key experimental variable that influences the quality and type of nanotubes produced.

The Power of High Temperature

Heat is the engine of the CVD process. The high temperatures inside the chamber (often 600-1200°C) provide the necessary energy to break the chemical bonds within the precursor gas molecules.

This decomposition reaction effectively liberates carbon atoms from the gas, making them available for deposition.

The Nanotube Growth Mechanism

The freed carbon atoms diffuse towards the heated substrate and dissolve into the metal catalyst nanoparticles.

When the catalyst particle becomes supersaturated with carbon, the carbon begins to precipitate out in a highly organized, cylindrical, graphitic form. This precipitation is the growth of the carbon nanotube.

Why CVD is the Dominant Method

While older methods like arc discharge and laser ablation exist, CVD has become the dominant commercial and research process for producing CNTs. This is due to several distinct advantages.

Superior Control and Versatility

The CVD process offers unparalleled control over the final product. By precisely adjusting parameters like temperature, gas composition, pressure, and flow rate, researchers can influence the nanotubes' diameter, length, and quality (e.g., single-walled vs. multi-walled).

High Scalability

Unlike other methods, CVD systems can be scaled up for large-volume, continuous production. This scalability is the primary reason it has become the standard for industrial applications, where large quantities of CNTs are required.

Process Variations for Specific Needs

The fundamental principles of CVD can be adapted. For example, Plasma-Enhanced CVD (PECVD) uses an electric field to create plasma, which helps decompose the precursor gas.

This allows the reaction to occur at much lower temperatures, making it possible to grow CNTs directly on sensitive substrates (like plastics or certain electronics) that cannot withstand the heat of traditional CVD.

Understanding the Trade-offs

Despite its advantages, CVD is not without its challenges. Understanding these is key to its successful implementation.

Catalyst Contamination

Because nanotubes grow directly from metal catalyst particles, the final product often contains residual metallic impurities. Post-growth purification steps are almost always required, adding complexity and cost to the process.

Process Complexity

Achieving high-quality, uniform CNTs requires extremely precise control over multiple variables. Small fluctuations in temperature or gas flow can lead to defects in the nanotube structure or inconsistent batch quality.

Safety and Handling

The precursor gases used in CVD (like methane and acetylene) are often flammable and require specialized handling and safety protocols. The process also generates waste byproducts that must be managed properly.

Making the Right Choice for Your Goal

The optimal approach depends entirely on your end objective.

- If your primary focus is large-scale industrial production: Standard thermal CVD is the established, scalable, and most cost-effective method for producing CNTs in bulk.

- If your primary focus is precise control for R&D: The high tunability of CVD parameters makes it the ideal platform for researching and fabricating specific types of CNTs with desired properties.

- If your primary focus is integration with sensitive electronics: A lower-temperature variation like Plasma-Enhanced CVD (PECVD) is the necessary choice to avoid damaging the underlying components.

Ultimately, Chemical Vapor Deposition provides a robust and adaptable platform for creating one of the most remarkable materials ever discovered.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Gas-to-solid conversion using thermal energy to decompose a carbon source gas. |

| Key Components | Substrate, metal catalyst nanoparticles (e.g., Fe, Ni, Co), and a carbon precursor gas (e.g., methane). |

| Primary Advantage | Superior control over CNT properties (diameter, length, quality) and high scalability for industrial production. |

| Common Variations | Thermal CVD (high temp) and Plasma-Enhanced CVD (PECVD) for lower-temperature growth on sensitive materials. |

Ready to integrate high-quality carbon nanotubes into your research or production line? The precise control and scalability of CVD are essential for success. KINTEK specializes in providing the lab equipment and consumables needed for reliable CNT synthesis. Our expertise supports laboratories in achieving consistent, high-yield results. Contact our experts today to discuss how we can meet your specific laboratory needs.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What is the floating catalyst method? A Guide to High-Yield CNT Production