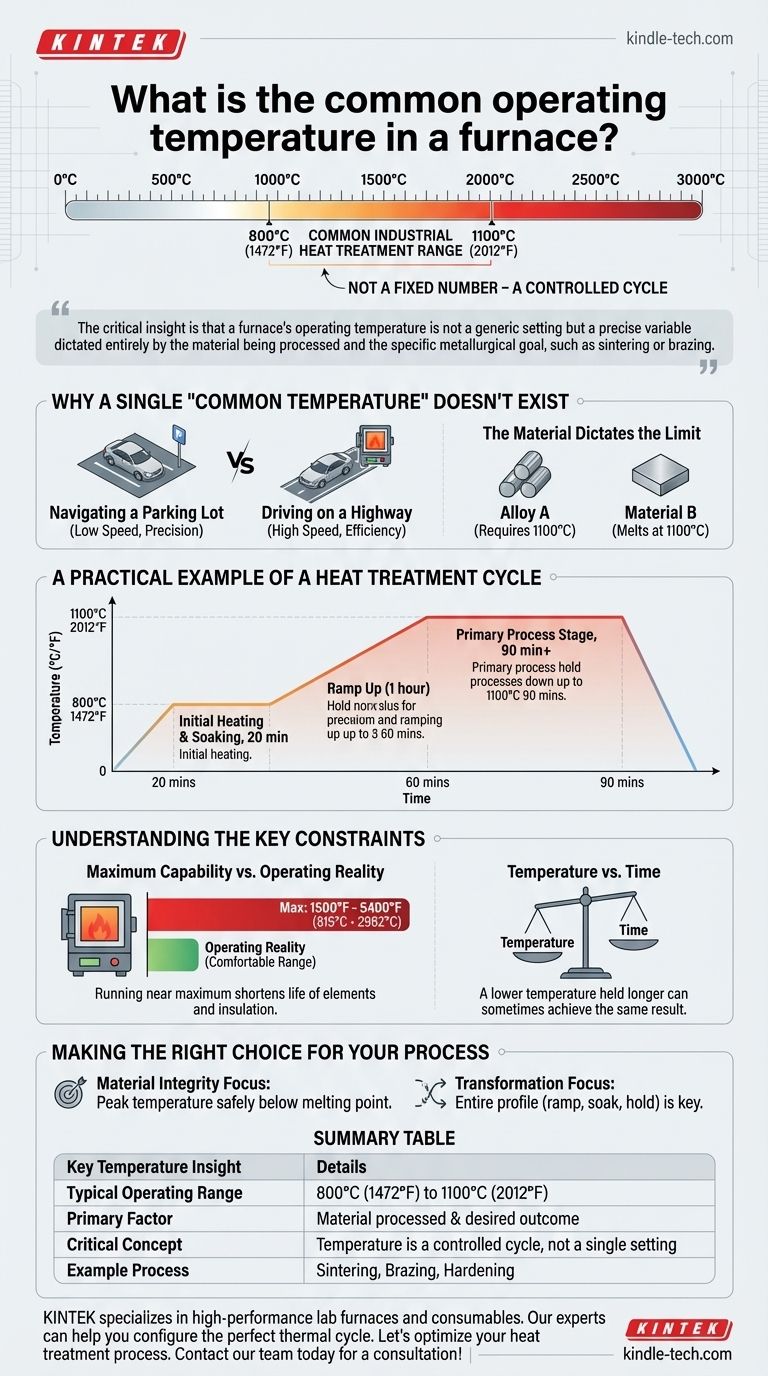

While there is no single universal temperature, a common operating range for industrial heat treatment processes is between 800°C (1472°F) and 1100°C (2012°F). This temperature is not a fixed number but is part of a carefully controlled cycle of heating and holding designed for a specific material and a desired outcome.

The critical insight is that a furnace's operating temperature is not a generic setting but a precise variable dictated entirely by the material being processed and the specific metallurgical goal, such as sintering or brazing.

Why a Single "Common Temperature" Doesn't Exist

Asking for a common furnace temperature is like asking for the common speed of a car; the correct answer depends entirely on the objective, whether you are navigating a parking lot or driving on a highway. The same principle applies to industrial furnaces.

The Goal Dictates the Heat

Different thermal processes are designed to achieve fundamentally different results, each requiring a unique temperature profile.

For example, sintering is a process that fuses particles together to create a solid object. The goal is to shape the material without liquefying it, meaning the temperature must be carefully controlled to remain below the material's melting point.

The Material Dictates the Limit

The properties of the material being processed set the absolute upper and lower bounds for any heat treatment.

A specific alloy may require a temperature of 1100°C to achieve the desired crystalline structure, while another material might be damaged or melt at that same temperature.

A Practical Example of a Heat Treatment Cycle

Instead of a single temperature, furnaces operate on a programmed cycle with multiple stages. A typical program for a vacuum furnace illustrates this well.

The Initial Heating and Soaking Stage

The furnace might first be raised to 800°C (1472°F) and held there for a set period, such as 20 minutes. This initial "soak" allows the temperature to equalize throughout the part and can help burn off any contaminants.

The Primary Process Stage

Next, the temperature is ramped up slowly over an hour to the primary operating temperature, perhaps 1100°C (2012°F).

The furnace then holds this peak temperature for an extended period, often 90 minutes or more. This is the stage where the intended metallurgical transformation, like bonding or hardening, actually occurs.

Understanding the Key Constraints

Simply setting a furnace to a high temperature is ineffective and often damaging. The process is a balance of multiple factors.

Maximum Capability vs. Operating Reality

While many industrial furnace systems have a maximum capability between 1,500°F and 5,400°F (815°C to 2982°C), they rarely operate at these limits.

Running a furnace near its maximum temperature shortens the life of its heating elements and insulation. Most processes are designed to run well within the furnace's comfortable operating range for consistency and longevity.

Temperature vs. Time

The duration of the temperature hold is just as critical as the temperature itself. A lower temperature held for a longer time can sometimes achieve the same result as a higher temperature held for a shorter period. This trade-off is a key part of process engineering.

Making the Right Choice for Your Process

Selecting the correct temperature profile requires a clear understanding of your final objective and your starting material.

- If your primary focus is material integrity: The most critical factor is ensuring your peak temperature remains safely below the material's melting point.

- If your primary focus is achieving a specific transformation: The entire temperature profile—including ramp rates, soaking stages, and hold times—is more important than any single peak number.

Ultimately, the correct furnace temperature is a precise engineering decision, not a generic setting.

Summary Table:

| Key Temperature Insight | Details |

|---|---|

| Typical Operating Range | 800°C (1472°F) to 1100°C (2012°F) |

| Primary Factor | Material being processed & desired metallurgical outcome |

| Critical Concept | Temperature is part of a controlled cycle, not a single setting |

| Example Process | Sintering, Brazing, Hardening |

Selecting the right furnace and temperature profile is critical for your lab's success. KINTEK specializes in high-performance lab furnaces and consumables, providing the precise temperature control and durability needed for sintering, brazing, and other heat treatment processes. Our experts can help you configure the perfect thermal cycle for your specific materials and goals.

Let's optimize your heat treatment process. Contact our team today for a consultation!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- How does an alumina tube furnace with a controlled atmosphere simulate conditions in CSP environments? Master Accuracy.

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere

- Why is a high-purity alumina lining required for high-temperature tube furnaces? Ensure Accurate Biomass Research

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab