At its core, a muffle furnace is constructed as a system of nested layers. Its design centers on an insulated inner chamber, known as the muffle, which contains the sample and is heated externally. This core chamber is surrounded by heating elements, a thick layer of insulation, and a protective outer casing, all managed by a precise temperature control system.

The essential principle of a muffle furnace's construction is isolation. Every component works together to create a perfectly contained and controlled high-temperature environment, separating the sample from the raw heating source to ensure uniform heating and prevent contamination.

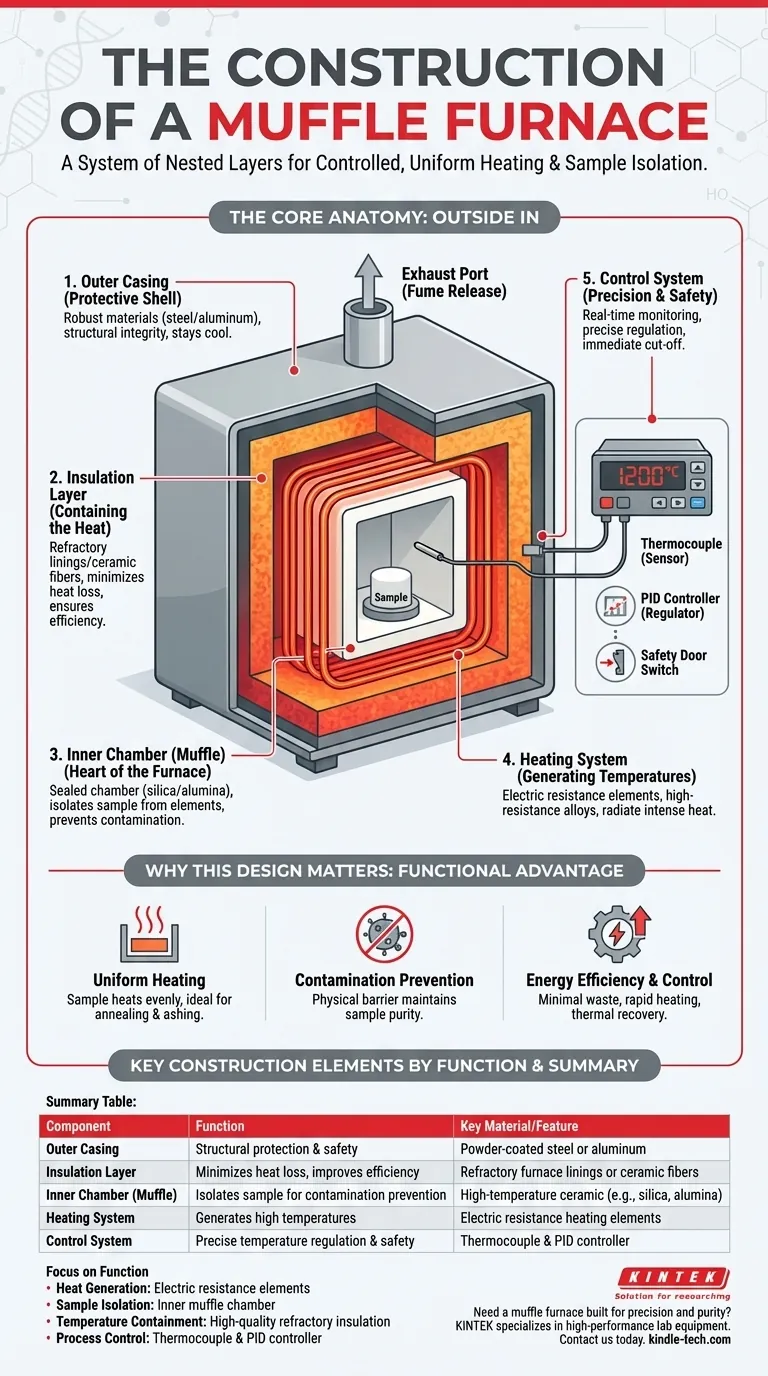

The Core Anatomy: How a Muffle Furnace is Built

Understanding the construction of a muffle furnace involves examining it from the outside in. Each component serves a distinct and critical function in achieving and maintaining extreme temperatures safely and efficiently.

The Outer Casing: The Protective Shell

The outermost layer is the outer casing or frame. It provides structural integrity and protects the internal components from the external environment.

This shell is typically fabricated from robust materials like powder-coated steel or aluminum, designed to withstand the rigors of a lab or industrial setting while remaining relatively cool to the touch.

The Insulation Layer: Containing the Heat

Between the outer casing and the internal components lies a thick layer of insulation. This is one of the most critical parts of the furnace's construction.

This layer, often made from refractory furnace linings or ceramic fibers, minimizes heat loss. This ensures the furnace operates efficiently, maintains temperature stability, and keeps the external surface safe.

The Inner Chamber (The Muffle): The Heart of the Furnace

The defining component is the muffle, or inner chamber. This is a sealed chamber made from materials like silica and aluminum that can withstand extreme thermal stress.

Its primary purpose is to isolate the sample. The heating elements are located outside this chamber, heating it from all sides. This separation prevents any direct contact between the sample and the heating elements.

The Heating System: Generating Extreme Temperatures

The heat itself is generated by electric resistance heating elements. These are often high-resistance wires, such as iron-chromium-aluminum alloys, that are wrapped around the outside of the muffle chamber.

When electrical current passes through these elements, they glow red-hot, radiating intense heat that is absorbed by the muffle and transferred uniformly to the sample inside.

The Control System: Precision and Safety

The entire heating process is managed by an electronic control unit. This system ensures the desired temperature is reached, maintained, and monitored accurately.

It consists of three key parts:

- A thermocouple, which is a sensor that extends into the chamber to measure the internal temperature in real-time.

- A temperature controller, often a microprocessor-based PID regulator, which interprets the thermocouple's signal and adjusts power to the heating elements.

- Safety features, such as a door switch that immediately cuts power to the heating elements when the door is opened, protecting both the operator and the components.

Some designs also include an exhaust port or release hole to safely vent any gases or fumes produced during the heating process.

Why This Design Matters: The Functional Advantage

The specific construction of a muffle furnace is not arbitrary; it is engineered to deliver distinct advantages over other types of furnaces. The layered, isolated design directly contributes to its performance.

Uniform Heating

Because the sample is not exposed directly to the raw heat of the elements, the muffle chamber heats up evenly on all sides. This radiated heat provides a highly uniform temperature environment, which is critical for processes like ashing, annealing, and heat-treating.

Contamination Prevention

The physical barrier of the muffle is essential for maintaining sample purity. It prevents any particles or byproducts from the heating elements (or from combustion in fuel-fired models) from contaminating the material being heated.

Energy Efficiency and Control

The combination of high-quality insulation and a precise PID controller allows the furnace to achieve and hold setpoint temperatures with minimal energy waste. This design enables rapid heating, excellent thermal recovery after opening the door, and controlled cooling cycles.

Key Construction Elements by Function

To summarize the furnace's design, it's best to think about which components fulfill each core function.

- If your primary focus is heat generation: The key components are the electric resistance heating elements, typically made from a high-resistance alloy.

- If your primary focus is sample isolation: The defining feature is the inner muffle chamber, which physically separates the sample from the heating source.

- If your primary focus is temperature containment: High-quality refractory insulation is critical for maintaining efficiency and ensuring the outer casing remains safe.

- If your primary focus is process control: The system relies on a thermocouple to measure temperature and a PID controller to regulate power with high precision.

Ultimately, understanding this construction reveals that a muffle furnace is far more than a simple hot box; it is a precision instrument designed for control and purity.

Summary Table:

| Component | Function | Key Material/Feature |

|---|---|---|

| Outer Casing | Structural protection and safety | Powder-coated steel or aluminum |

| Insulation Layer | Minimizes heat loss, improves efficiency | Refractory furnace linings or ceramic fibers |

| Inner Chamber (Muffle) | Isolates sample for contamination prevention | High-temperature ceramic (e.g., silica, alumina) |

| Heating System | Generates high temperatures | Electric resistance heating elements (e.g., iron-chromium-aluminum alloy) |

| Control System | Precise temperature regulation and safety | Thermocouple sensor and PID controller |

Need a muffle furnace built for precision and purity? KINTEK specializes in high-performance lab equipment, including muffle furnaces designed for uniform heating and contamination-free results. Our expertise ensures you get the right equipment for your specific laboratory needs, from research to quality control. Contact our experts today to discuss how we can support your application with reliable, efficient heating solutions.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How hot can a muffle furnace get? Find the Right Temperature for Your Lab

- What role does a high-temperature muffle furnace play in sol-gel synthesis? Mastering Nickel Nanomaterial Production

- What role does a muffle furnace play in the thermal treatment and synthesis of Li2.5Y0.5Zr0.5Cl6? Master Your Synthesis

- Why is it important to know moisture and ash content in food? Ensure Safety, Quality, and Compliance

- Why is a high-temperature muffle furnace necessary for APTES-modified TiO2? Optimize Your Material Phase Transformation

- How did you determine the sintering temperature for different materials? Achieve Optimal Densification and Performance

- How does a high-temperature calcination furnace contribute to the structural stability of sulfated zirconia catalysts?

- What are the uses of muffle furnace in pharmaceutical industry? Essential for Drug Purity & Safety