Determining the cost of a plasma pyrolysis machine is less about finding a single price tag and more about understanding the key variables that define a complete system. While a simple answer is impossible without detailed specifications, the initial capital investment for these systems is significant, typically ranging from several hundred thousand dollars for small-scale research units to tens of millions for full-scale industrial or municipal plants.

The final cost is not for the machine in isolation, but for an entire integrated system. The price is fundamentally driven by its processing capacity, the type of waste it will handle, and the necessary downstream equipment for gas cleaning and energy recovery.

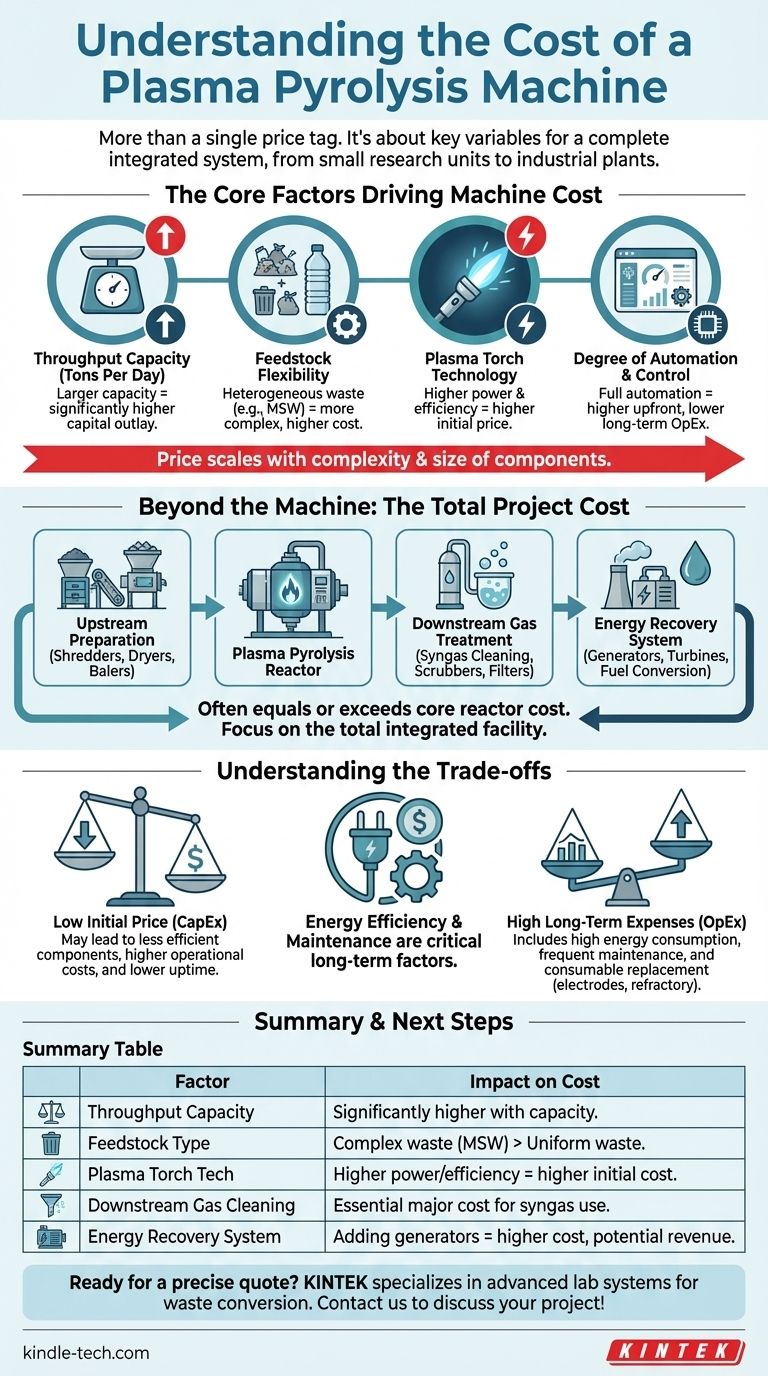

The Core Factors Driving Machine Cost

The "machine" is actually a system of interconnected components, and the price scales with the complexity and size of each. Understanding these primary drivers is the first step in assessing financial viability.

Throughput Capacity (Tons Per Day)

This is the single largest factor influencing cost. A system designed to process 1 ton of waste per day is fundamentally different in scale, engineering, and material requirements than a plant designed for 50 tons per day.

The relationship isn't linear; larger plants often have a lower cost-per-ton but require a much larger total capital outlay.

Feedstock Flexibility

The type of waste (feedstock) the system is designed to handle directly impacts its complexity and cost. A system for uniform, pre-processed industrial plastic waste will be simpler and less expensive than one engineered to handle heterogeneous Municipal Solid Waste (MSW), which requires more robust front-end sorting and handling.

Plasma Torch Technology

The heart of the system is the plasma generator. The type (e.g., DC arc, microwave), power rating (kW), and number of torches determine the system's effectiveness and operational range. Higher-power, more durable, and more efficient torch systems carry a higher price tag.

Degree of Automation and Control

A fully automated plant with sophisticated sensors, programmable logic controllers (PLCs), and remote monitoring capabilities will have a higher upfront cost than a system requiring more manual operation. However, automation can significantly reduce long-term operational costs and improve safety and efficiency.

Beyond the Machine: The Total Project Cost

Focusing only on the pyrolysis reactor is a common and costly mistake. A functional plasma pyrolysis facility requires significant investment in supporting infrastructure, which can often equal or exceed the cost of the core reactor.

Upstream Preparation

Waste rarely arrives ready for processing. Costs in this category include shredders, dryers, balers, and sorting equipment needed to bring the feedstock to the required size, consistency, and moisture content for efficient pyrolysis.

Downstream Gas Treatment (Syngas Cleaning)

The raw synthesis gas (syngas) produced by pyrolysis is not immediately usable. It contains particulates, tars, and other contaminants that must be removed. This requires a gas treatment train, which can include cyclones, scrubbers, and filters. The level of cleaning depends on the final use of the gas and is a major cost center.

Energy Recovery System

What you do with the cleaned syngas is a critical cost decision. Simply flaring the gas is the cheapest option but provides no return. Using it to power a gas engine or turbine to generate electricity adds significant cost but also creates a revenue stream. Converting it to liquid fuels like diesel requires even more complex and expensive Fischer-Tropsch or similar conversion technology.

Understanding the Trade-offs

A low initial price can sometimes hide significant long-term expenses. A credible assessment must balance capital and operational costs.

Capital Expenditure vs. Operational Expenditure

A less expensive system might use lower-grade materials or less efficient components. This can lead to higher operational costs through increased maintenance, more frequent replacement of parts like torch electrodes or refractory lining, and lower overall system uptime.

High Energy Consumption

Plasma torches are powerful but energy-intensive. The cost of electricity to operate the system is a primary operational expense that must be factored into any financial model. The efficiency of the plasma generator becomes a critical factor in the system's long-term profitability.

Maintenance and Consumables

These are planned, recurring costs. Plasma torch electrodes have a finite lifespan and require regular replacement. The refractory lining inside the reactor will also degrade over time and need to be repaired or replaced. These costs are unavoidable and must be budgeted for.

How to Get an Accurate Quote

To move from a general understanding to a specific price, you must provide vendors with a detailed picture of your project.

- If your primary focus is early-stage research: Begin by defining your specific waste stream (type, composition, moisture content, daily volume), as this is the foundational data every vendor will require.

- If your primary focus is developing a business case: Expand your financial model to include the total project cost—site prep, upstream sorting, downstream gas cleaning, and energy recovery—not just the pyrolysis unit.

- If your primary focus is engaging with vendors: Prepare a detailed Request for Quotation (RFQ) that specifies your throughput requirements, feedstock characteristics, and desired output (e.g., electricity, heat, fuel) to receive truly comparable proposals.

A thorough understanding of your project's specific goals and constraints is the essential first step toward determining the true cost of a plasma pyrolysis solution.

Summary Table:

| Factor | Impact on Cost |

|---|---|

| Throughput Capacity | Higher tons/day = significantly higher cost |

| Feedstock Type | Complex waste (e.g., MSW) = higher cost than uniform waste |

| Plasma Torch Tech | Higher power/efficiency torches = higher initial cost |

| Downstream Gas Cleaning | Essential for syngas use; major cost component |

| Energy Recovery System | Adding generators for electricity = higher cost but potential revenue |

Ready to get a precise quote for your plasma pyrolysis project?

KINTEK specializes in advanced laboratory equipment and consumables, including systems for waste conversion research and development. Our experts can help you navigate the complexities of system design and cost based on your specific feedstock and capacity requirements.

Contact us today to discuss your project and discover how KINTEK's solutions can bring efficiency and reliability to your lab's pyrolysis initiatives.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

People Also Ask

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty