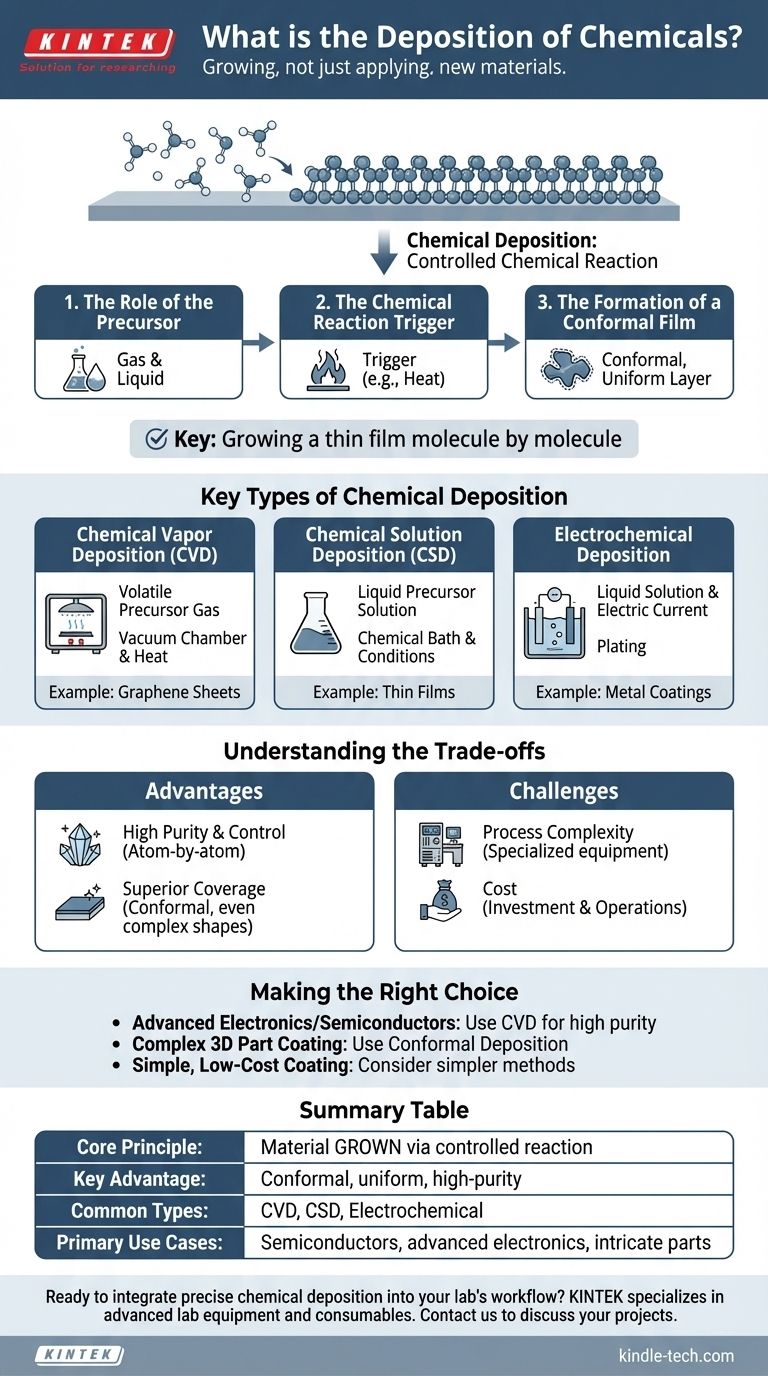

In essence, chemical deposition is a process where a new, solid material is created directly on a surface through a controlled chemical reaction. Unlike simple painting or spraying, the coating isn't just applied; it self-assembles and bonds to the substrate molecule by molecule from a fluid or gas precursor.

The critical distinction of chemical deposition is that it grows a thin film on an object rather than simply placing it there. This fundamental difference is what allows for the creation of exceptionally pure, uniform, and complex material layers.

How Chemical Deposition Fundamentally Works

The process can be broken down into three core stages, regardless of the specific technique used. Each stage is critical for controlling the final properties of the deposited film.

The Role of the Precursor

A precursor is the starting chemical compound that contains the elements you want to deposit. This precursor is introduced to the process as a fluid—either a gas or a liquid solution.

The choice of precursor is critical as it dictates the composition of the final coating and the conditions (like temperature) required for the reaction.

The Chemical Reaction Trigger

The precursor does not simply stick to the surface. A specific trigger, most commonly heat, is used to initiate a chemical reaction.

This reaction breaks down the precursor molecules, freeing the desired atoms or molecules to bond with the target surface, known as the substrate.

The Formation of a Conformal Film

As the reaction occurs at the surface, a solid layer builds up. A key advantage of this method is that the resulting film is often conformal.

A conformal coating follows the exact topography of the surface, covering grooves, edges, and complex 3D shapes with a layer of uniform thickness. This is a significant advantage over directional methods that can't easily coat hidden surfaces.

Key Types of Chemical Deposition

While the underlying principle is the same, the method changes based on the state of the precursor and the trigger used.

Chemical Vapor Deposition (CVD)

This is one of the most common and powerful techniques. In CVD, a volatile precursor gas is injected into a vacuum chamber containing the substrate.

The chamber is heated, causing the gas to react or decompose and deposit a thin, high-purity film onto the substrate's surface. This precision makes it a leading method for manufacturing advanced materials.

A prime example is its use in producing high-quality, low-defect graphene sheets for high-performance electronics and sensors.

Chemical Solution Deposition (CSD)

Also known as chemical bath deposition, this method uses a liquid precursor solution. The substrate is immersed in a chemical bath where controlled conditions cause the dissolved precursors to react and deposit a solid film onto its surface.

Electrochemical Deposition

This process, often called plating, also uses a liquid solution. However, it relies on an electric current to drive the chemical reaction, pulling ions from the solution to deposit them onto the substrate.

Understanding the Trade-offs

Chemical deposition is a powerful tool, but its advantages come with specific challenges that make it unsuitable for every application.

Advantage: High Purity and Control

Because the material is built atom-by-atom, chemical deposition can produce films with extremely high purity and a well-ordered crystal structure. This level of control is essential for advanced applications like semiconductors.

Advantage: Superior Coverage

The conformal nature of the deposition is a major benefit. It ensures that even highly complex or intricate objects are coated evenly on all exposed surfaces, something difficult to achieve with line-of-sight physical methods.

Challenge: Process Complexity and Cost

These techniques often require specialized equipment, such as vacuum chambers, high-temperature furnaces, and systems to handle potentially volatile precursor chemicals. This complexity increases both the initial investment and operational costs.

Making the Right Choice for Your Goal

Selecting a deposition technique depends entirely on the required quality, material, and cost constraints of your project.

- If your primary focus is advanced electronics or semiconductors: You will rely on Chemical Vapor Deposition (CVD) for its ability to create exceptionally pure and uniform thin films.

- If your primary focus is coating a complex 3D part with a uniform layer: The conformal nature of chemical deposition makes it a far superior choice over methods like physical spraying.

- If your primary focus is a simple, low-cost protective coating: Simpler and less expensive methods might be more suitable, as chemical deposition is an advanced process for performance-critical applications.

Ultimately, chemical deposition is the go-to manufacturing process when the material's internal quality and surface uniformity are absolutely critical to its function.

Summary Table:

| Aspect | Description |

|---|---|

| Core Principle | A solid material is grown on a surface via a controlled chemical reaction, not simply applied. |

| Key Advantage | Creates conformal, uniform, and high-purity coatings, even on complex 3D shapes. |

| Common Types | Chemical Vapor Deposition (CVD), Chemical Solution Deposition (CSD), Electrochemical Deposition. |

| Primary Use Cases | Semiconductor manufacturing, advanced electronics, high-performance sensors, and coating intricate parts. |

Ready to integrate precise chemical deposition into your lab's workflow?

KINTEK specializes in the advanced lab equipment and consumables required for these critical processes. Whether you need a reliable CVD system, high-temperature furnaces, or expert consultation to achieve superior thin films, we have the solutions for your laboratory's needs.

Contact us today to discuss how we can support your advanced material deposition projects!

Visual Guide

Related Products

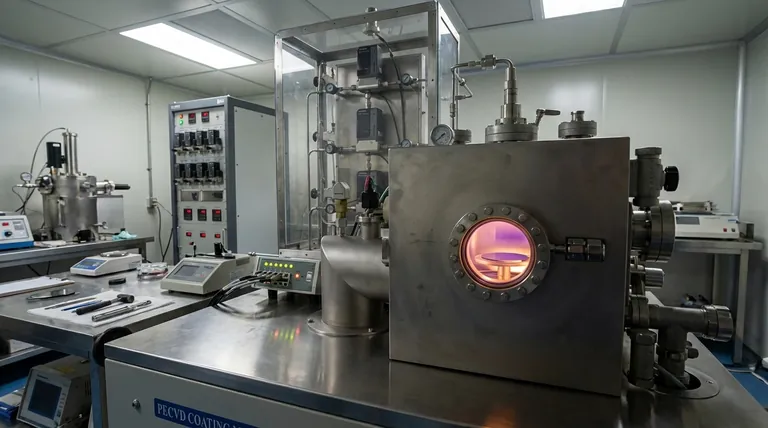

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is low pressure chemical Vapour deposition? Achieve Superior Thin Film Uniformity

- How does magnetron sputtering work? A Guide to High-Quality Thin Film Deposition

- Which gas is used in CVD process? Unlocking the Precise Gas Mixtures for Superior Thin Films

- How does a CVD system facilitate electrode materials for microbial fuel cells? Precision Nanomaterial Growth

- What is LPCVD advantages and disadvantages? Balancing Film Quality and Thermal Budget

- What is the significance of a heating system composed of a PID controller and a Variac in Tungsten ALD? | KINTEK

- What is the difference between chemical Vapour deposition? A Guide to CVD Process Variations

- What are precursors in CVD process? The Essential Ingredient for Thin-Film Success