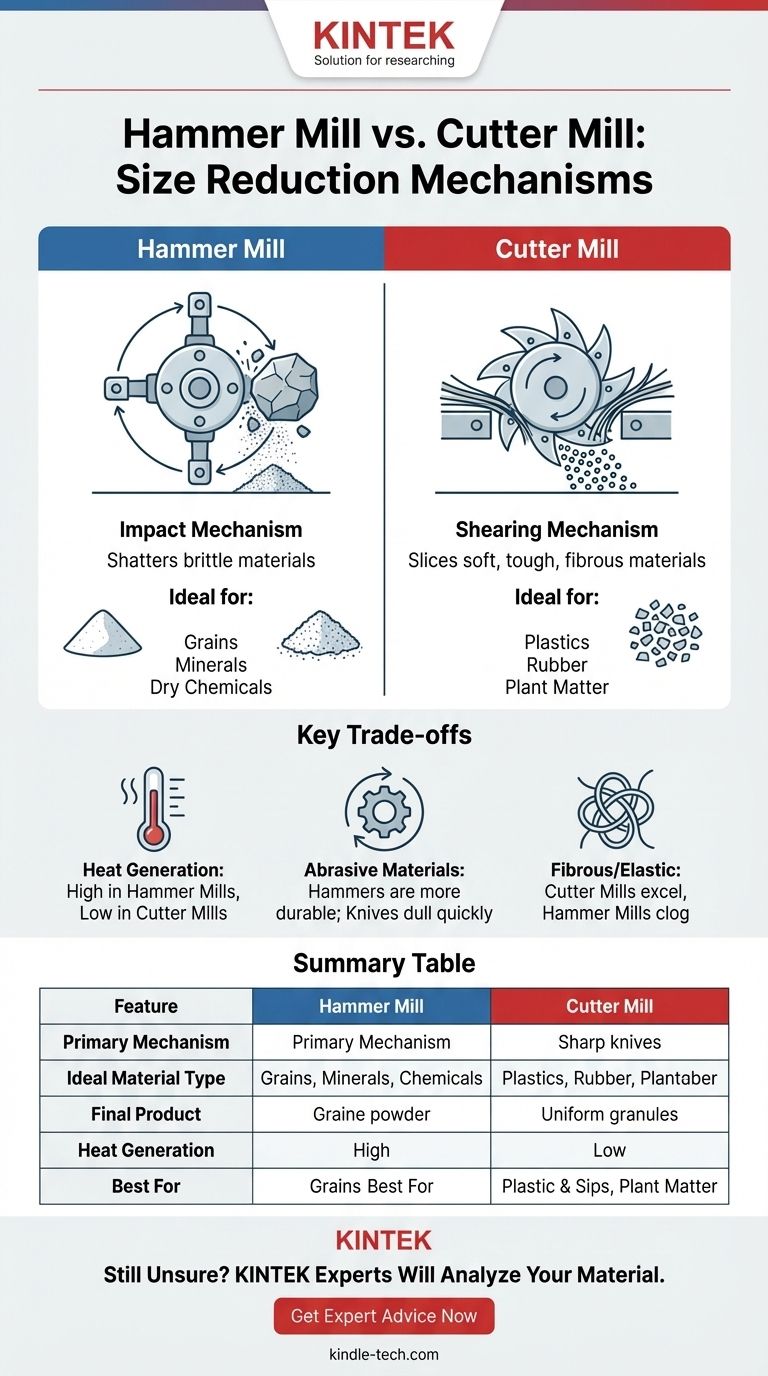

At its core, the difference between a hammer mill and a cutter mill lies in their mechanism for size reduction. A hammer mill shatters material through high-speed impact, while a cutter mill slices material through a scissor-like shearing action. This fundamental difference dictates which types of materials each mill can effectively process.

The choice is not about which mill is "better," but which is correct for your material's properties. Hammer mills pulverize hard, brittle substances, whereas cutter mills granulate soft, fibrous, or elastic ones. Using the wrong mill results in inefficiency, poor product quality, and potential equipment damage.

The Hammer Mill: Pulverizing Through Impact

A hammer mill operates on the principle of brute force. It is designed to take larger, brittle materials and smash them into a fine powder.

Operating Principle

Inside a hammer mill, a central rotor spins at extremely high speed. Attached to this rotor are multiple swinging "hammers" that are free to pivot. As material is fed into the grinding chamber, these hammers strike it repeatedly, shattering it against the chamber walls and other particles until it is small enough to pass through a screen at the bottom.

Material Suitability

Hammer mills excel at processing materials that are brittle, crystalline, or dry and fibrous. They are ineffective on soft or gummy materials, which will simply deform under impact rather than shatter.

Common applications include grinding grains, spices, minerals, dry chemicals, and certain types of biomass.

The Final Product

The output of a hammer mill is typically a fine to coarse powder. The final particle size is determined primarily by the size of the holes in the discharge screen, the rotor speed, and the number and type of hammers used.

The Cutter Mill: Slicing Through Shear

A cutter mill, also known as a granulator, functions more like a high-speed set of scissors than a sledgehammer. It is designed for precision cutting, not pulverization.

Operating Principle

A cutter mill features a rotor with a set of sharp, angled knives. As this rotor spins, its knives pass in close proximity to stationary "bed" knives mounted on the chamber wall. This action creates a high-speed shearing or cutting motion that precisely chops the material fed into the chamber.

Material Suitability

Cutter mills are the ideal choice for materials that are soft, tough, elastic, or fibrous. These are materials that would clog a hammer mill or simply bounce around without breaking down.

Common applications include granulating plastics, rubber, leather, wood, cables, and tough plant matter like stems and leaves.

The Final Product

The output of a cutter mill is uniform granules or chips, not a fine powder. Just as with a hammer mill, the final particle size is controlled by the size of the perforations in the discharge screen.

Understanding the Key Trade-offs

Choosing between these two technologies requires understanding their limitations in different scenarios.

Heat Generation

Hammer mills generate significant heat through friction and impact. This can be a major problem for heat-sensitive materials, which may melt, degrade, or lose their desired properties. Cutter mills generate far less heat, making them superior for these applications.

Abrasive Materials

The knives in a cutter mill must be sharp to be effective. Highly abrasive materials will dull these knives very quickly, leading to high maintenance costs and downtime. The blunt hammers in a hammer mill are far more durable and better suited for moderately abrasive feeds.

Fibrous and Elastic Materials

This is the clearest dividing line. A hammer mill cannot effectively process tough, fibrous, or elastic materials. They will absorb the impact, potentially wrap around the rotor, and cause the machine to clog. A cutter mill is specifically designed to slice through these materials with ease.

Selecting the Right Mill for Your Material

Your material's physical properties are the sole determinant of the correct mill for your process.

- If your primary focus is producing fine powder from brittle materials (like grains, minerals, or chalk): A hammer mill is your optimal choice due to its high-impact pulverizing action.

- If your primary focus is creating uniform granules from soft, fibrous, or elastic materials (like plastics or plant matter): A cutter mill is the correct tool because its shearing action prevents material deformation and excessive heat buildup.

- If your material is tough but also abrasive: You must weigh the high maintenance of a cutter mill's knives against the outright inability of a hammer mill to process the material.

Ultimately, a successful size reduction process begins with a clear understanding of what you are grinding.

Summary Table:

| Feature | Hammer Mill | Cutter Mill |

|---|---|---|

| Primary Mechanism | Impact / Shattering | Shearing / Slicing |

| Ideal Material Type | Brittle, Crystalline, Dry Fibrous | Soft, Tough, Elastic, Fibrous |

| Final Product | Fine to Coarse Powder | Uniform Granules or Chips |

| Heat Generation | High | Low |

| Best For | Grains, Minerals, Dry Chemicals | Plastics, Rubber, Plant Matter |

Still Unsure Which Mill is Right for Your Material?

Choosing the wrong mill can lead to inefficiency, poor product quality, and equipment damage. KINTEK, your trusted partner in lab equipment, can help you make the right choice.

We specialize in providing reliable size reduction solutions for laboratories. Our experts will analyze your material's properties—whether it's brittle, fibrous, elastic, or heat-sensitive—and recommend the perfect mill for your specific needs.

Contact us today using the form below for a personalized consultation. Let KINTEK help you optimize your process and achieve superior results with the right equipment.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- Laboratory Single Horizontal Jar Mill

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is a planetary ball mill? Achieve Rapid, High-Energy Grinding for Advanced Materials

- What is the process of planetary mill? Unlock High-Energy Grinding for Fine Powders

- What is the working principle of planetary ball mill? Unlock High-Energy Grinding for Nanoscale Results

- What is a planetary ball mill? Achieve Superior Fine Grinding and Mixing

- What are the effects of ball milling? A Deep Dive into Mechanical Alloying and Material Transformation