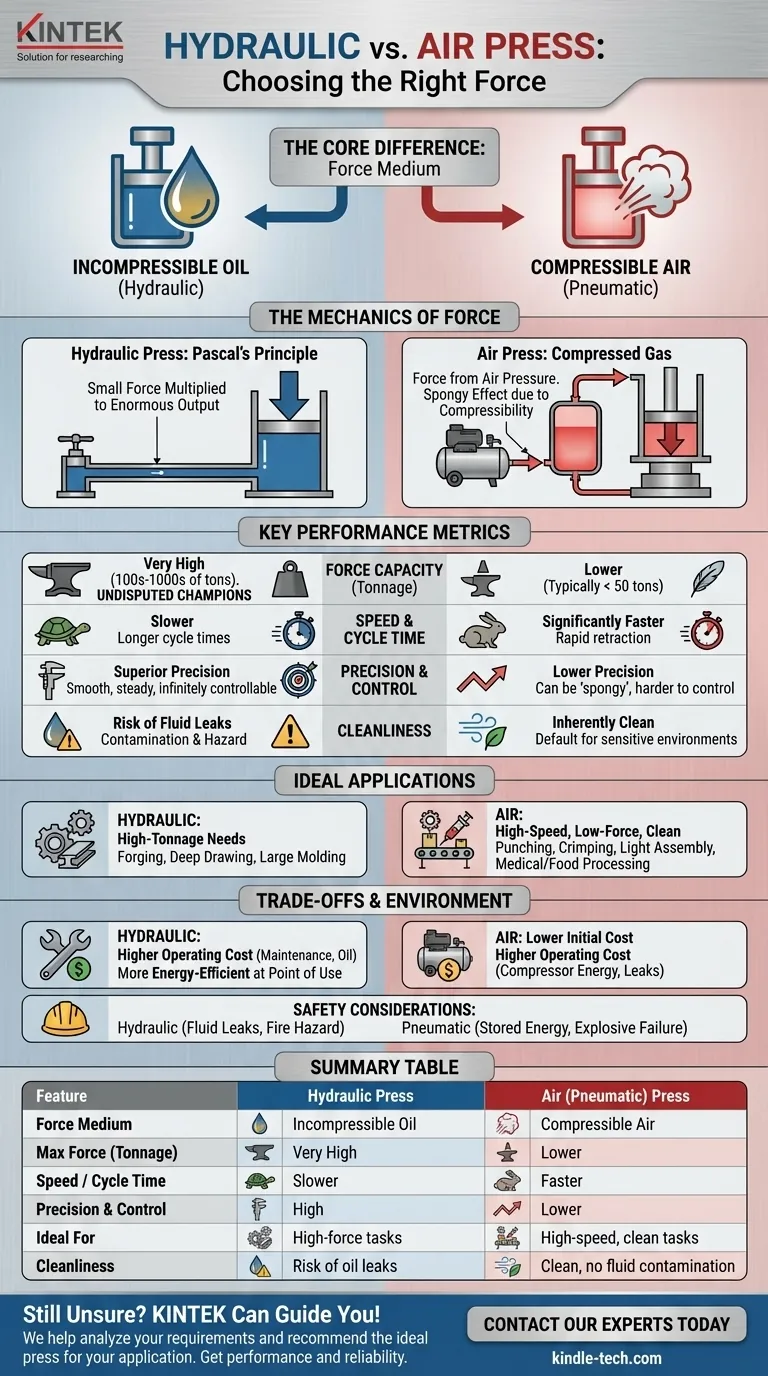

The core difference between a hydraulic press and an air press is the medium they use to generate force. A hydraulic press uses an incompressible liquid, typically oil, to create immense and steady force, while an air (pneumatic) press uses compressible air to perform tasks at much higher speeds but with significantly less force. This fundamental distinction dictates their ideal applications, costs, and operational characteristics.

Your choice isn't about which technology is inherently "better," but which is the appropriate tool for your specific application. Hydraulic presses are the definitive solution for high-tonnage needs, while air presses excel in high-speed, lower-force tasks where cleanliness and cycle time are paramount.

The Mechanics of Force Generation

To understand which press is right for you, you must first understand how they fundamentally work. Their method of generating force influences every other performance metric.

Hydraulic Presses: The Power of Incompressible Fluid

A hydraulic press operates on Pascal's Principle. A small pump moves a volume of incompressible hydraulic oil into a large cylinder, acting on a piston.

Because the oil cannot be compressed, the pressure is distributed evenly, and a small amount of force applied by the pump is multiplied into an enormous amount of output force. This allows for the generation of extremely high tonnage.

Air (Pneumatic) Presses: The Speed of Compressed Gas

An air press uses a simpler mechanism, directing compressed air from a reservoir into a cylinder to drive a piston. The force is generated by the pressure of the air acting on the piston's surface area.

However, air is a compressible gas. This means that as the press meets resistance, the air will compress slightly before delivering its full force. This creates a "spongy" effect compared to the rock-solid feel of a hydraulic system.

Comparing Key Performance Metrics

The choice between hydraulic and pneumatic systems becomes clear when you compare them across critical operational factors.

Force Capacity (Tonnage)

Hydraulic presses are the undisputed champions of force. They can be engineered to produce thousands of tons of pressure, making them essential for heavy-duty applications like forging metal, deep drawing, and large-scale molding.

Air presses operate at a much lower force range. They are typically used for applications requiring anywhere from a few hundred pounds to a few tons of force, rarely exceeding 50 tons even in specialized designs.

Speed and Cycle Time

Air presses are significantly faster. Compressed air can be vented to the atmosphere almost instantly, allowing the piston to retract rapidly. This makes them ideal for high-volume, repetitive tasks like punching, crimping, and light assembly.

Hydraulic systems are inherently slower. Moving a viscous fluid into and out of a large cylinder takes more time, resulting in longer cycle times.

Precision and Control

Hydraulic systems offer superior precision. The incompressibility of oil allows for very smooth, steady, and infinitely controllable force application throughout the entire stroke. You can hold a specific tonnage for an extended period with minimal variation.

The compressibility of air makes it more difficult to achieve precise force control with a pneumatic press. The force can fluctuate, and it's challenging to "inch" the press or hold a specific intermediate pressure with the same accuracy as a hydraulic system.

Understanding the Trade-offs and Environment

Beyond pure performance, the operational environment and long-term costs play a critical role in the decision.

Cost of Ownership

Initially, smaller air presses are often less expensive than their hydraulic counterparts. They also have simpler designs with fewer components.

However, operating costs can be higher for pneumatic systems due to the energy required to run a large air compressor. Leaks in air lines are common and represent a significant, often hidden, energy waste. Hydraulic systems are generally more energy-efficient at the point of use but require costly maintenance for oil, filters, and seals.

Cleanliness and Contamination

Air presses are inherently clean. They run on air and exhaust it into the atmosphere, making them the default choice for industries where contamination is a major concern, such as food processing, medical device manufacturing, and electronics assembly.

Hydraulic presses pose a constant risk of fluid leaks. A ruptured hose or a failed seal can contaminate products and create a hazardous, slippery work environment.

Safety Considerations

Both systems have inherent risks. Hydraulic fluid leaks can create slip and fire hazards. However, the energy in a hydraulic system dissipates quickly when a leak occurs.

Pneumatic systems store a large amount of energy in the form of compressed air. In the event of a catastrophic component failure, this stored energy can be released explosively, creating a more significant danger than a typical hydraulic leak.

Making the Right Choice for Your Application

Your decision must be guided by the primary demands of your work. Analyze your priorities to select the correct technology.

- If your primary focus is maximum force and precision: A hydraulic press is the necessary tool for high-tonnage forming, stamping, molding, or any task requiring immense, controllable power.

- If your primary focus is speed and high-volume production: An air press is superior for rapid, repetitive tasks like assembly, crimping, or punching that do not require extreme force.

- If your primary focus is operating in a clean environment: An air press is the clear winner, as it completely eliminates the risk of hydraulic fluid contamination in sensitive manufacturing processes.

Ultimately, choosing between these two technologies is a clear choice between brute, controllable power and clean, high-speed operation.

Summary Table:

| Feature | Hydraulic Press | Air (Pneumatic) Press |

|---|---|---|

| Force Medium | Incompressible Oil | Compressible Air |

| Max Force (Tonnage) | Very High (100s-1000s of tons) | Lower (Typically < 50 tons) |

| Speed / Cycle Time | Slower | Faster |

| Precision & Control | High (Smooth, steady force) | Lower (Can be 'spongy') |

| Ideal For | High-force tasks: forging, molding | High-speed, clean tasks: assembly, punching |

| Cleanliness | Risk of oil leaks | Clean, no fluid contamination |

Still Unsure Which Press is Right for Your Lab or Production Line?

Choosing the correct press technology is critical for your project's efficiency, safety, and success. The team at KINTEK specializes in lab equipment and consumables, and we have the expertise to guide you to the perfect solution.

We can help you:

- Analyze your specific force, speed, and cleanliness requirements.

- Recommend the ideal press type for your application, whether it's for high-tonnage material testing or high-speed, clean-room assembly.

- Provide reliable equipment that meets your exact specifications.

Don't leave your project to chance. Contact our experts today for a personalized consultation and ensure you get the performance and reliability your work demands.

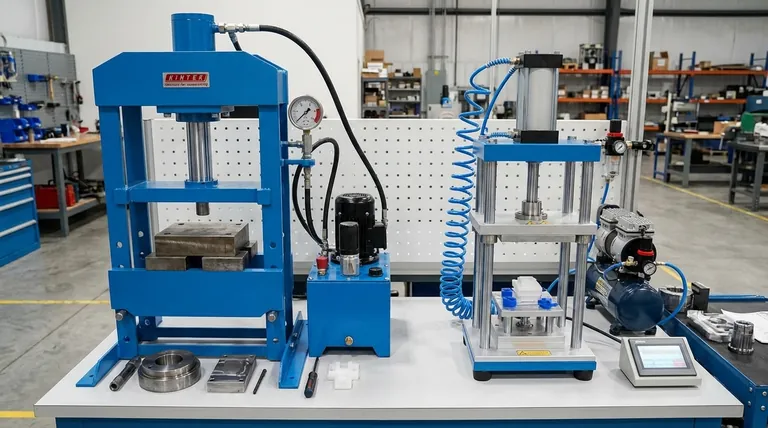

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Lab Heat Press

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy