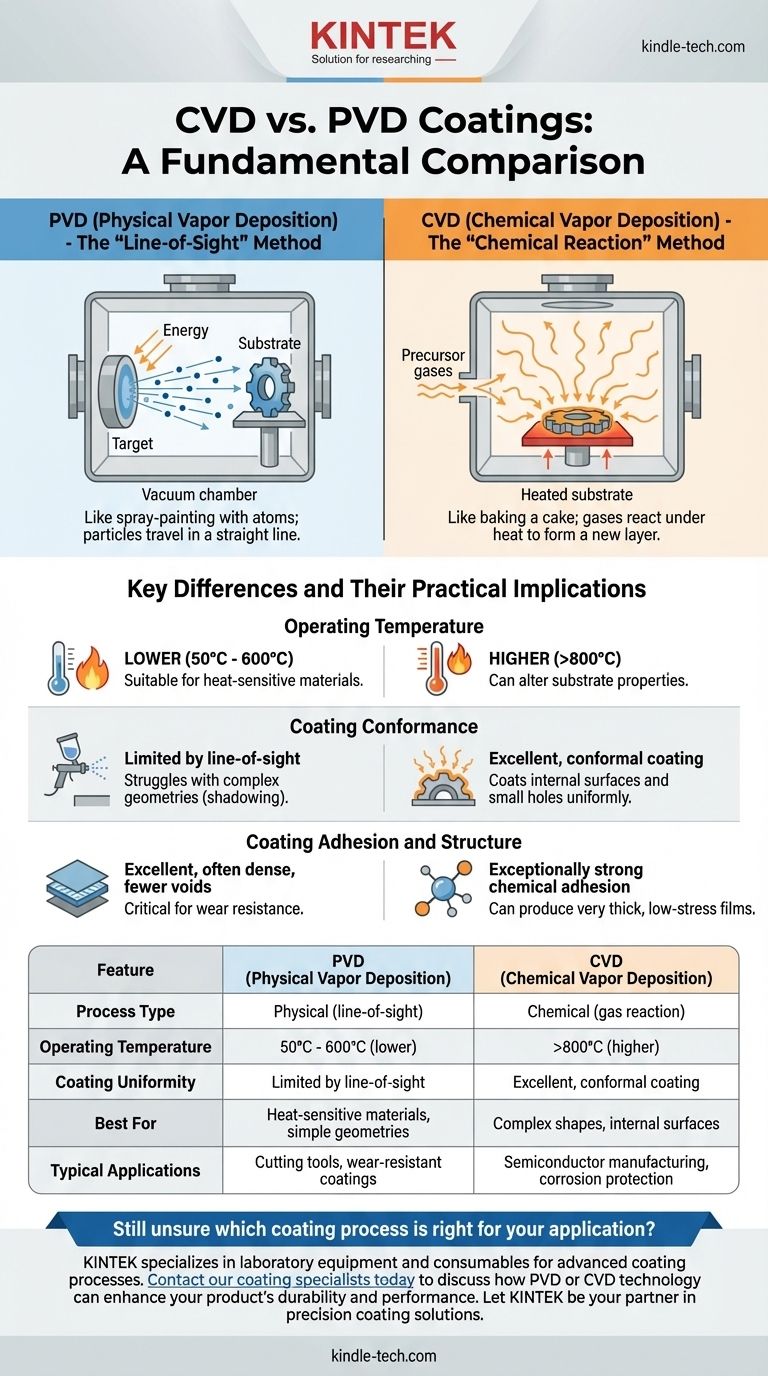

The fundamental difference between CVD and PVD lies in the nature of the deposition process. Physical Vapor Deposition (PVD) is a physical process that uses a line-of-sight technique to deposit a thin film from a vaporized source material onto a substrate. In contrast, Chemical Vapor Deposition (CVD) uses a chemical reaction between precursor gases inside a chamber to grow a solid film on the substrate's surface.

The core distinction is simple: PVD is like spray-painting with atoms, where particles travel in a straight line to coat a surface. CVD is more like baking a cake, where ingredients (gases) react under heat to form a new, solid layer that grows on the substrate.

The Core Mechanisms: Physical vs. Chemical

To understand which coating to choose, you must first understand how their foundational processes differ. These mechanisms dictate everything from operating temperature to the final properties of the coating.

How PVD Works: The "Line-of-Sight" Method

PVD is a physical process. It begins with a solid or liquid source material—the coating "target"—inside a vacuum chamber.

Energy is applied to this target, causing it to vaporize into atoms or molecules. These vaporized particles then travel in a straight line through the vacuum and deposit onto the substrate, building up the coating layer by layer.

This "line-of-sight" nature means the coating is only applied to surfaces that are directly exposed to the vapor source.

How CVD Works: The "Chemical Reaction" Method

CVD is a chemical process. It involves introducing specific precursor gases into a reaction chamber that contains the heated substrate.

The high temperature of the substrate provides the energy needed to trigger a chemical reaction between the gases.

This reaction causes a solid material to form and deposit onto the substrate, creating a dense and uniform coating. Because the gases fill the entire chamber, the coating grows on all exposed surfaces simultaneously.

Key Differences and Their Practical Implications

The distinction between a physical and chemical process is not merely academic. It has direct consequences for your material, your part's geometry, and the performance of the final coating.

Operating Temperature

CVD typically requires very high temperatures (often over 800°C) to drive the necessary chemical reactions. This can alter the properties of heat-sensitive substrates, such as certain steels or plastics.

PVD is a lower-temperature process, generally performed between 50°C and 600°C. This makes it suitable for a much wider range of substrate materials that cannot withstand the heat of CVD.

Coating Conformance

CVD's gaseous nature allows it to create a highly conformal coating. The gases can penetrate small holes and complex internal geometries, ensuring a completely uniform layer on even the most intricate parts.

PVD's line-of-sight deposition means it excels at coating flat or external surfaces but struggles with complex geometries. Areas not directly in the path of the vapor source will receive little to no coating, an effect known as "shadowing."

Coating Adhesion and Structure

CVD coatings are grown directly on the substrate through chemical bonds, often resulting in exceptionally strong adhesion. The process can produce very thick, low-stress films.

PVD coatings also have excellent adhesion, but the bond is primarily mechanical and metallurgical. PVD films are often very dense, with fewer voids or imperfections compared to some CVD processes, which is critical for wear resistance.

Understanding the Trade-offs and Limitations

Neither technology is universally superior. Your choice depends entirely on balancing the benefits against the inherent limitations of each process.

Substrate Compatibility is Crucial

The high heat of the CVD process is its primary limitation. You cannot coat materials like aluminum, titanium alloys, or hardened tool steels without fundamentally altering their mechanical properties. PVD is the default choice for heat-sensitive materials.

Geometry Dictates the Method

If you need to coat the internal surfaces of a complex part, CVD is often the only viable option. For external surfaces or simple geometries where line-of-sight deposition is sufficient, PVD is a highly effective and versatile choice.

Cost and Complexity

Both are industrial processes, but CVD can involve more complex setups and the handling of potentially hazardous precursor gases. The choice of specific PVD or CVD techniques can also significantly impact cost and cycle time.

Making the Right Choice for Your Application

Your decision should be guided by your substrate material and the primary function of the coating.

- If your primary focus is coating complex shapes or internal surfaces uniformly: CVD is almost always the superior choice due to its non-line-of-sight, gaseous process.

- If your primary focus is coating heat-sensitive materials (like plastics, aluminum, or hardened steel): PVD is the necessary choice because its lower operating temperatures will not damage the substrate.

- If your primary focus is achieving a very dense, hard, and thin wear-resistant coating on a cutting tool: PVD is a common industry standard for this application due to its excellent finish and toughness.

- If your primary focus is creating a very thick, pure, and corrosion-resistant layer: CVD can often build thicker layers than PVD and is a standard for applications like semiconductor manufacturing.

By understanding the core process—physical versus chemical—you can confidently select the technology that aligns with your material, geometry, and performance goals.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical (line-of-sight) | Chemical (gas reaction) |

| Operating Temperature | 50°C - 600°C (lower) | >800°C (higher) |

| Coating Uniformity | Limited by line-of-sight | Excellent, conformal coating |

| Best For | Heat-sensitive materials, simple geometries | Complex shapes, internal surfaces |

| Typical Applications | Cutting tools, wear-resistant coatings | Semiconductor manufacturing, corrosion protection |

Still unsure which coating process is right for your application?

KINTEK specializes in laboratory equipment and consumables for advanced coating processes. Our experts can help you select the perfect solution based on your substrate material, part geometry, and performance requirements.

Contact our coating specialists today to discuss how PVD or CVD technology can enhance your product's durability and performance. Let KINTEK be your partner in precision coating solutions.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the precursor gas in PECVD? The Key to Low-Temperature Thin Film Deposition

- How plasma is generated in PECVD? A Step-by-Step Breakdown of the Process

- What are the advantages of PECVD over CVD? Achieve High-Quality Thin Films at Lower Temperatures

- Why is PECVD better than CVD? Achieve Superior Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process