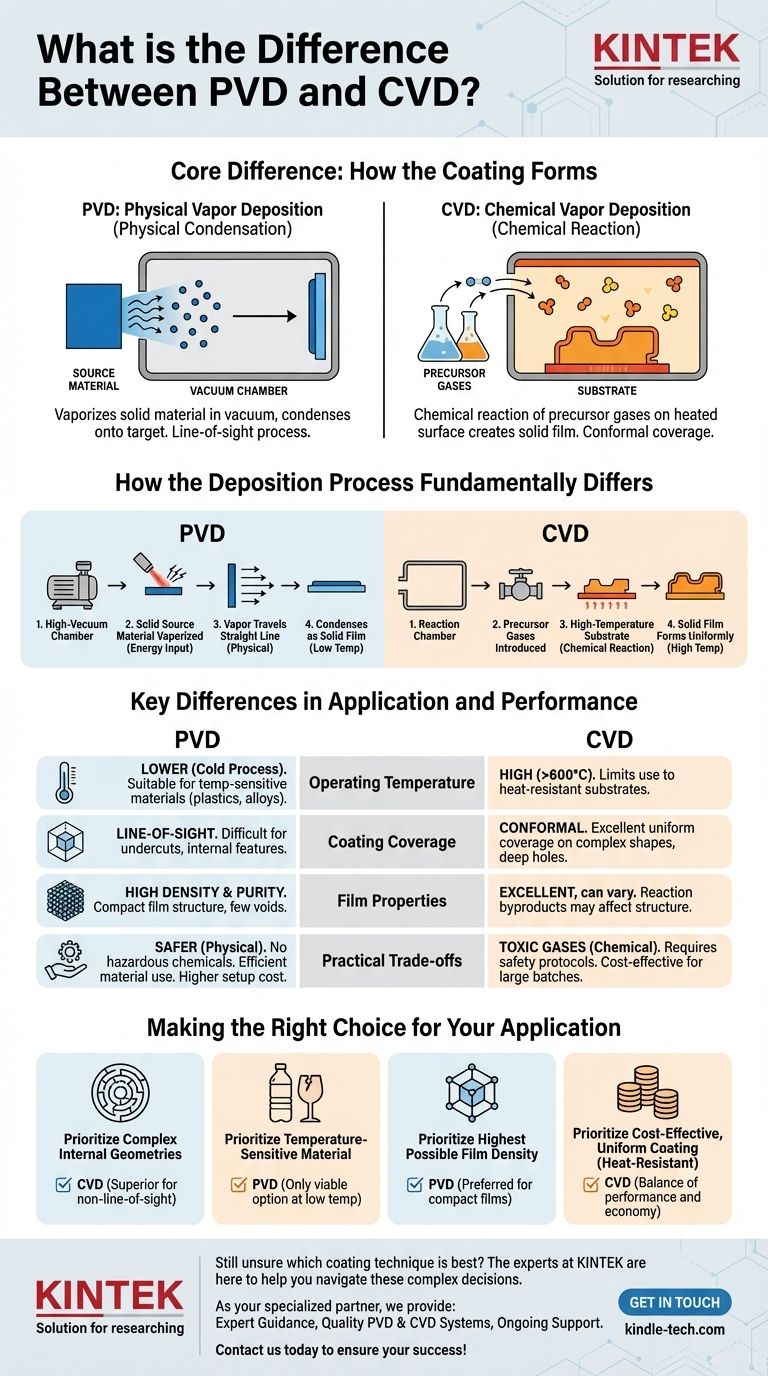

At their core, the fundamental difference between PVD and CVD lies in how the coating material arrives and forms on a surface. Chemical Vapor Deposition (CVD) uses a chemical reaction between precursor gases on a heated surface to create a solid film. In contrast, Physical Vapor Deposition (PVD) uses a purely physical process, where a solid material is vaporized in a vacuum and then condenses onto the target surface.

The choice between these two powerful techniques hinges on a critical trade-off: CVD offers excellent, uniform coverage on complex shapes via a high-temperature chemical process, while PVD provides a dense, high-purity coating at lower temperatures using a direct, line-of-sight physical process.

How the Deposition Process Fundamentally Differs

To select the right method, you must first understand the mechanism behind each. The "how" dictates the "what"—the properties of the final coating.

CVD: A Chemical Reaction on the Surface

In Chemical Vapor Deposition, volatile precursor gases are introduced into a reaction chamber containing the substrate.

The substrate is heated to a high temperature, which provides the energy needed to trigger a chemical reaction between the gases.

This reaction results in the formation of a solid material that deposits uniformly across all exposed surfaces of the substrate, creating the desired coating.

PVD: A Physical Condensation of Vapor

Physical Vapor Deposition is a mechanical, not chemical, process. It takes place in a high-vacuum chamber.

A solid source material (the "target") is bombarded with energy—often through heating or ion sputtering—causing it to vaporize into individual atoms or molecules.

This vapor then travels in a straight line through the vacuum and condenses as a thin, solid film on the cooler substrate placed in its path.

Key Differences in Application and Performance

The differences in their underlying processes lead to distinct advantages and limitations that directly impact which method you should choose.

Operating Temperature and Substrate Compatibility

CVD typically requires very high temperatures (often >600°C) to drive the necessary chemical reactions. This limits its use to substrates that can withstand extreme heat without deforming or melting.

PVD is considered a "cold" process by comparison, operating at much lower temperatures. This makes it suitable for a wide range of materials, including plastics, certain alloys, and other temperature-sensitive substrates.

Coating Coverage and Geometry

Because CVD relies on a gas that permeates the entire chamber, it provides a highly conformal coating. It excels at uniformly covering complex shapes, deep holes, and internal surfaces.

PVD is a line-of-sight process. The vaporized material travels in a straight line from the source to the substrate, making it difficult to coat undercuts or intricate internal features without complex part rotation.

Film Properties and Density

PVD coatings are known for their high density and low number of voids or defects. The physical condensation process results in a very pure and compact film structure.

While excellent, CVD coatings can sometimes have different structural properties due to the nature of the chemical reaction and byproducts formed during deposition.

Understanding the Practical Trade-offs

Beyond the core science, practical considerations like cost, safety, and materials often guide the final decision.

Cost and Complexity

CVD can be a more cost-effective solution for coating large batches of parts, especially when uniform coverage on all surfaces is required.

PVD processes can be more expensive due to the need for high-vacuum equipment and more complex fixtures to hold and orient parts for line-of-sight coating.

Safety and Handling

The precursor gases used in CVD are often toxic, corrosive, or flammable, requiring stringent safety protocols and handling procedures.

PVD, being a physical process, avoids the use of hazardous reactive chemicals, generally making it a safer and easier process to manage.

Material Utilization

PVD is highly efficient in its use of source material. Since the vapor travels directly to the substrate, there is less wasted deposition on chamber walls compared to CVD.

Making the Right Choice for Your Application

Selecting the correct technique requires you to prioritize your project's most critical requirement.

- If your primary focus is coating complex internal geometries or deep holes: CVD is the superior choice due to its non-line-of-sight, gas-based deposition.

- If your primary focus is coating a temperature-sensitive material like plastic or a tempered alloy: PVD is the only viable option because it operates at significantly lower temperatures.

- If your primary focus is achieving the highest possible film density and purity: PVD is generally preferred for its ability to create compact films with fewer structural voids.

- If your primary focus is cost-effective, uniform coating on heat-resistant parts: CVD often provides an excellent balance of performance and economy.

Understanding these core principles allows you to select the deposition technique that aligns precisely with your material constraints and performance goals.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical (vaporization & condensation) | Chemical (gas reaction) |

| Temperature | Lower ("cold" process) | High (>600°C) |

| Coverage | Line-of-sight | Conformal (uniform on complex shapes) |

| Substrate Compatibility | Excellent for temperature-sensitive materials (e.g., plastics) | Limited to heat-resistant materials |

| Film Density | High density and purity | Excellent, but can vary with reaction byproducts |

| Safety | Generally safer (no hazardous gases) | Requires handling of toxic/corrosive gases |

Still unsure which coating technique is best for your specific project?

The choice between PVD and CVD is critical for achieving optimal performance, durability, and cost-efficiency. The experts at KINTEK are here to help you navigate these complex decisions.

As your specialized partner in lab equipment and consumables, we provide:

- Expert Guidance: Our technical specialists will analyze your substrate material, desired coating properties, and application requirements to recommend the ideal process.

- Quality Equipment: We supply reliable PVD and CVD systems tailored to your laboratory's scale and precision needs.

- Ongoing Support: From installation to maintenance, KINTEK ensures your coating processes run smoothly and effectively.

Contact us today to discuss your project and let KINTEK provide the solution that ensures your success. Get in touch via our contact form!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is meant by vapor deposition? A Guide to Atomic-Level Coating Technology

- What materials are deposited in PECVD? Discover the Versatile Thin-Film Materials for Your Application

- What is PECVD silicon deposition? Achieve Low-Temperature, High-Quality Thin Films

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method