In practice, the terms "firing" and "sintering" are often used interchangeably, but they describe different aspects of the same goal. Firing is the broad term for the entire process of heating a material in a furnace to achieve a desired hardness and density. Sintering is the specific, microscopic mechanism of atomic diffusion that causes the material’s particles to bond together and densify during the firing process.

Firing is the overall heating process you perform in a kiln or furnace. Sintering is the specific physical transformation that occurs during firing, where individual particles fuse into a solid mass without melting.

Breaking Down the Core Concepts

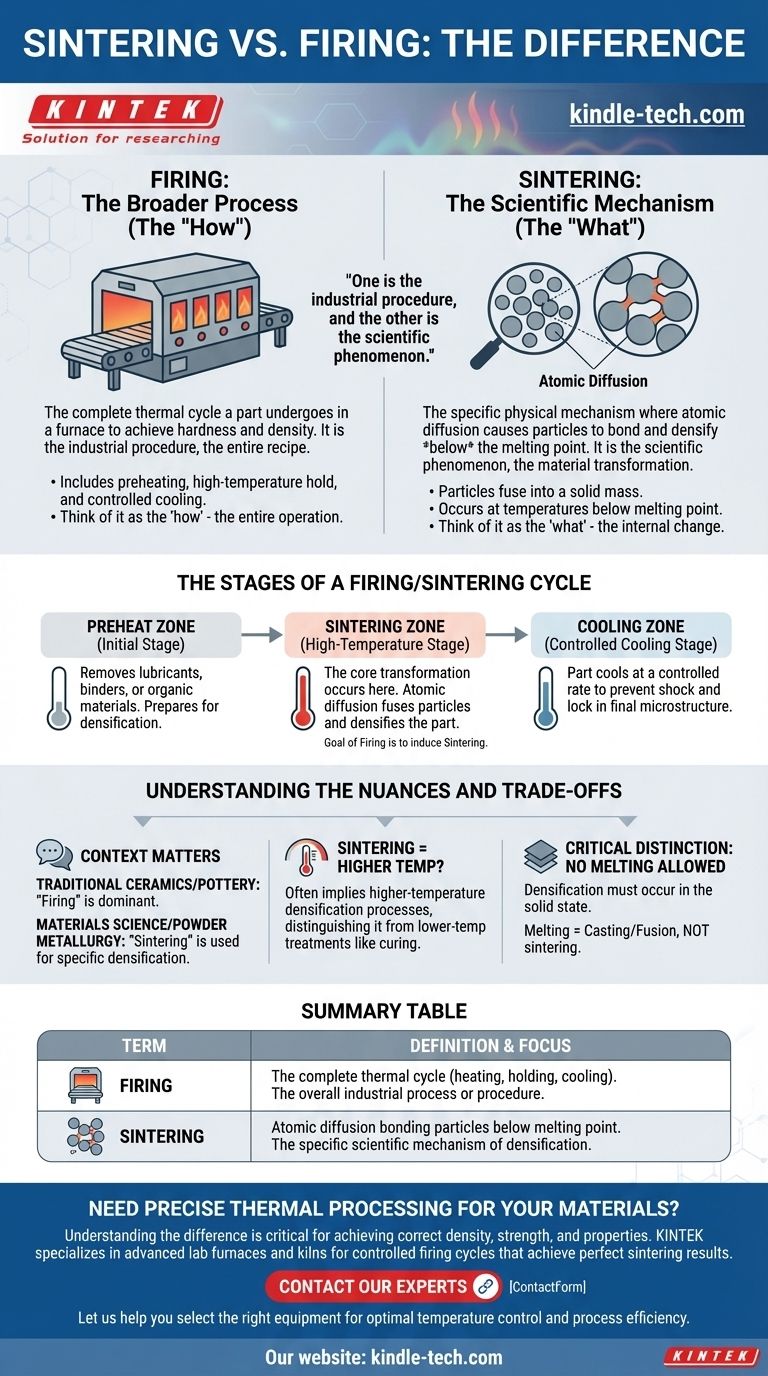

To grasp the difference, it's best to think of firing as the "how" and sintering as the "what." One is the industrial procedure, and the other is the scientific phenomenon.

What is Firing? The Broader Process

Firing is a general, historical term describing the complete thermal cycle a part undergoes in a furnace. This is the entire procedure from start to finish.

The process includes multiple stages, such as preheating to burn off binders, a high-temperature hold, and a controlled cooling phase. Think of "firing" as the complete recipe you follow.

What is Sintering? The Scientific Mechanism

Sintering is the specific physical mechanism that gives a fired part its strength and density. It is the process of atoms migrating between particles at high temperatures.

This atomic diffusion causes the "necks" between particles to grow and the pores between them to shrink and disappear. Crucially, this happens at a temperature below the material's melting point, causing particles to fuse together into a dense, solid object.

How Sintering and Firing Work Together

In most modern applications, especially with ceramics and powdered metals, the primary goal of firing is to induce sintering. The firing cycle is the carefully controlled environment created to make sintering happen successfully.

Sintering as the Goal of Firing

You fire a compacted powder or "green" part in order to sinter it. Firing is the action; sintering is the result.

A typical firing process in a tunnel kiln illustrates this relationship, moving the component through distinct temperature zones.

The Stages of a Firing/Sintering Cycle

- Preheat Zone: This initial, lower-temperature stage removes lubricants, binders, or other organic materials used during part formation.

- Sintering Zone: This is the high-temperature section of the furnace where the core transformation occurs. Atomic diffusion takes over, fusing particles and densifying the part.

- Cooling Zone: The part is cooled at a controlled rate to prevent thermal shock, cracking, and to lock in the final microstructure.

Understanding the Nuances and Trade-offs

While the relationship seems clear, context matters. The interchangeable use of these terms in industry can cause confusion, but the distinction becomes critical in technical and scientific settings.

Context is Everything

In traditional ceramics or pottery, "firing" is the dominant term. In materials science and powder metallurgy, "sintering" is used more frequently to describe the specific densification mechanism being studied or controlled.

Why "Sintering" Can Imply a Higher Temperature

Some sources state that sintering furnaces operate at higher temperatures than firing furnaces. This is because "sintering" is often used in high-performance fields to specify a densification process, distinguishing it from lower-temperature heat treatments (like curing) that might also be generically called "firing."

The Critical Distinction: No Melting Allowed

The defining feature of true sintering is that densification occurs entirely in the solid state. If the material melts and then re-solidifies, the process is called casting or fusion, not sintering. Maintaining temperature control to stay below the melting point is essential.

How to Use These Terms Correctly

Applying the right term depends entirely on your audience and your goal. Use this as a guide to communicate with clarity and precision.

- If your primary focus is the overall industrial process: Use "firing" to describe the entire furnace cycle, especially when talking to operators or in a general manufacturing context.

- If your primary focus is the material's transformation: Use "sintering" to describe the specific scientific mechanism of particle bonding and densification, especially in an engineering or R&D report.

- If your primary focus is high-performance materials: Use "sintering" to denote the critical high-temperature densification step, distinguishing it from other, lower-temperature heat treatments.

Understanding this distinction allows you to describe both the operational procedure and the fundamental material transformation with precision.

Summary Table:

| Term | Definition | Focus |

|---|---|---|

| Firing | The complete thermal cycle in a furnace (heating, holding, cooling). | The overall industrial process or procedure. |

| Sintering | The atomic diffusion that bonds particles together below the melting point. | The specific scientific mechanism of densification. |

Need precise thermal processing for your materials?

Understanding the nuances between sintering and firing is critical for achieving the correct density, strength, and properties in your ceramic or metal parts. KINTEK specializes in providing the advanced lab furnaces and kilns necessary for controlled firing cycles that achieve perfect sintering results.

Our experts can help you select the right equipment for your specific application, ensuring optimal temperature control and process efficiency. Contact us today to discuss your laboratory's thermal processing needs and let us help you achieve superior material performance.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between a muffle furnace and a normal furnace? Ensuring Sample Purity with Indirect Heating

- What is the temperature range of a laboratory muffle furnace? Find the Right Model for Your Application

- What are the conditions for a muffle furnace? Ensure Safety, Performance, and Longevity

- At what temperature does ceramic melt? A Guide to Ceramic Heat Resistance

- Why ceramics can withstand high temperature? Unlock the Secrets of Atomic Structure