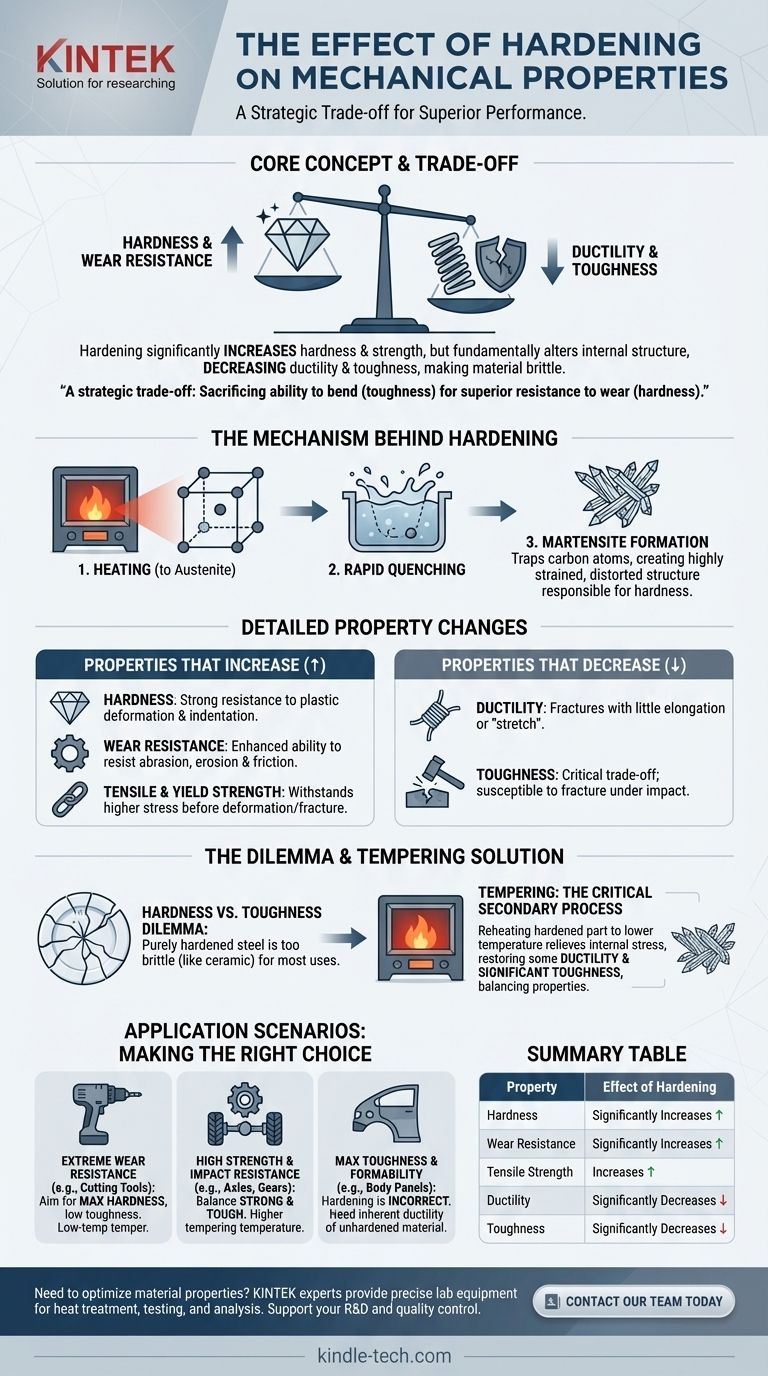

At its core, hardening a metal significantly increases its hardness, wear resistance, and tensile strength. However, this process fundamentally alters its internal structure, which also dramatically decreases its ductility and toughness, making the material much more brittle and susceptible to fracture.

The decision to harden a material is always a strategic trade-off. You are deliberately sacrificing the material's ability to bend and absorb impact (toughness) in exchange for a superior ability to resist scratching, indentation, and wear (hardness).

The Mechanism Behind Hardening

Hardening is not a single action but a controlled process, most commonly applied to medium and high-carbon steels. The goal is to create a specific crystal structure that gives the material its desired properties.

The Role of Heat and Quenching

The process involves heating the steel to a critical temperature where its internal crystal structure changes into a phase called austenite. In this state, carbon becomes uniformly dissolved within the iron.

The key step is the quench—a rapid cooling in a medium like water, oil, or air. This sudden drop in temperature traps the carbon atoms, preventing them from moving into their normal, relaxed positions.

Creating the Martensite Structure

This trapped-carbon state results in a new, highly strained, and distorted crystal structure known as martensite. It is the formation of martensite that is directly responsible for the dramatic increase in the material's hardness and strength.

A Detailed Look at Property Changes

The formation of martensite has a direct and predictable impact on the material's key mechanical properties.

Properties That Increase

- Hardness: This is the most significant change. The martensitic structure strongly resists plastic deformation and surface indentation. This is why hardened materials are used for cutting tools and wear surfaces.

- Wear Resistance: As a direct result of increased hardness, the material's ability to resist abrasion, erosion, and friction is greatly enhanced.

- Tensile and Yield Strength: The material can withstand a much higher level of stress before it begins to permanently deform (yield) or fracture (tensile). The internal strain of the martensite resists the atomic-level slipping that constitutes deformation.

Properties That Decrease

- Ductility: This is the material's ability to deform under tensile stress, like being drawn into a wire. A hardened material will fracture with very little elongation or "stretch."

- Toughness: This is arguably the most critical trade-off. Toughness is the ability to absorb energy and deform without fracturing. Because the hardened structure is so rigid, cracks can propagate through it very easily with little energy input, especially under sharp impact.

Understanding the Trade-offs

A purely hardened, untempered piece of steel is often too brittle for most practical applications. It has immense strength but can shatter like glass if dropped or struck. This is why understanding the inherent compromises is critical for any engineering design.

The Hardness vs. Toughness Dilemma

Think of the difference between a ceramic plate and a copper sheet. The ceramic is extremely hard and scratch-resistant but shatters with a single sharp impact. The copper is soft and easily scratched but can be bent, dented, and deformed extensively before it fails.

Hardening pushes a material far toward the ceramic end of this spectrum. The goal of heat treatment is often to find the optimal balance between these two opposing properties for a specific application.

The Critical Role of Tempering

To achieve this balance, a secondary process called tempering is almost always performed after hardening. Tempering involves reheating the hardened part to a lower temperature and holding it for a set time.

This process relieves some of the internal stress from the quench and allows the martensite to transform slightly, regaining a small amount of ductility and a significant amount of toughness. The higher the tempering temperature, the more toughness is restored, but at the cost of reducing some of the peak hardness and strength.

Internal Stress and Distortion

The rapid and often uneven cooling during the quench introduces significant internal stresses into the material. This can cause parts to warp, distort, or even crack during the hardening process itself, a risk that must be managed through process control.

Making the Right Choice for Your Goal

Hardening is not a universal improvement; it is a specialized tool used to achieve a specific performance outcome. The decision to use it, and how to temper it afterward, depends entirely on the intended function of the component.

- If your primary focus is extreme wear resistance (e.g., cutting tools, bearings): You will aim for maximum hardness and accept the resulting low toughness, using only a low-temperature temper to relieve stress.

- If your primary focus is high strength with impact resistance (e.g., axles, structural bolts, gears): You will use a higher tempering temperature after hardening to develop a strong but also tough final part that can withstand operational loads and shocks.

- If your primary focus is maximum toughness and formability (e.g., car body panels, simple brackets): Hardening is the incorrect process, as you need the inherent ductility of a softer, unhardened material.

Ultimately, hardening is not about making a material "better" in every way; it's about precisely tailoring its properties to survive and perform within a specific engineering environment.

Summary Table:

| Property | Effect of Hardening |

|---|---|

| Hardness | Significantly Increases |

| Wear Resistance | Significantly Increases |

| Tensile Strength | Increases |

| Ductility | Significantly Decreases |

| Toughness | Significantly Decreases |

Need to optimize your material's properties for a specific application? The experts at KINTEK can help. We specialize in providing the precise lab equipment and consumables needed for heat treatment processes, material testing, and analysis. Whether you're developing cutting tools requiring maximum hardness or structural components needing a balance of strength and toughness, we have the solutions to support your R&D and quality control.

Contact our team today to discuss how we can meet your laboratory's unique needs.

Visual Guide

Related Products

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does a laboratory hydraulic hot press ensure the quality of PHBV/natural fiber composites? Expert Guide

- Why is a hydraulic press used for pre-deformation treatment? Enhance Coating Hardness & Thermal Stability

- What role does a laboratory hydraulic hot press play in rice husk-based composite boards? Achieve Structural Density

- What is the purpose of using a laboratory hydraulic press for nanocomposites? Ensure Precise Material Characterization

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces