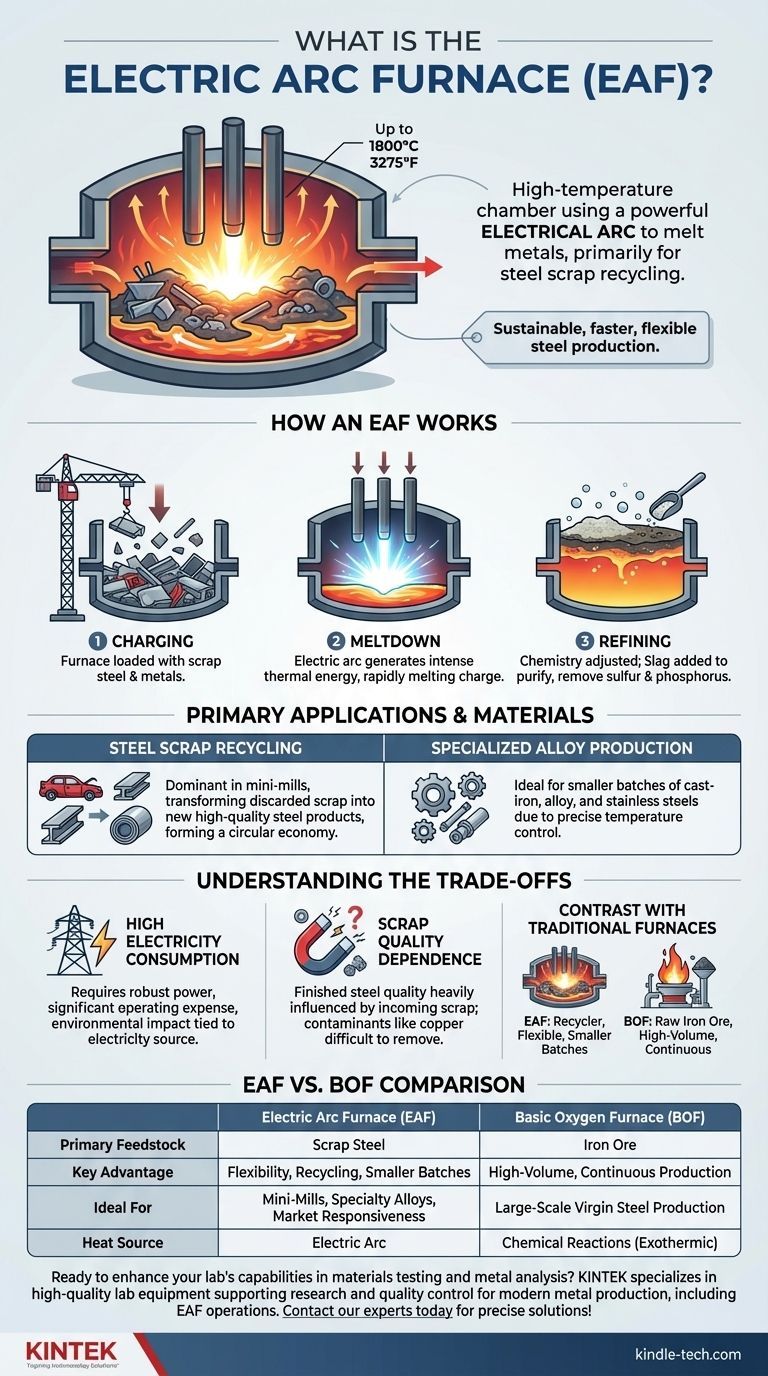

At its core, an electric arc furnace (EAF) is a high-temperature chamber that uses a powerful electrical arc to melt metals. This process is primarily used to recycle steel scrap, transforming it into new, high-quality steel products by generating immense heat—up to 1800°C (3275°F)—through a controlled plasma discharge.

The electric arc furnace is a cornerstone of modern recycling. It bypasses the need for raw iron ore by using electricity to efficiently melt down and refine existing scrap metal, making it a faster, more flexible, and often more sustainable method of steel production.

How an Electric Arc Furnace Works

The operation of an EAF is a multi-stage process that leverages the intense energy of electricity to convert solid metal into a molten, refinable liquid.

The Principle of the Electric Arc

The heat source is not a flame but an electric arc. This is a sustained plasma discharge, essentially a continuous, high-energy spark, that forms between graphite electrodes and the metallic charge within the furnace.

This arc converts electrical energy into intense thermal energy, creating a pocket of plasma that rapidly melts the scrap metal it contacts.

The Step-by-Step Melting Process

The furnace operates in a distinct sequence to ensure efficient melting and purification.

-

Charging: The process begins by loading the furnace, typically from the top, with a carefully selected mix of scrap steel and other metals.

-

Meltdown: The large graphite electrodes are lowered into the furnace. A high voltage is applied, striking an arc between the electrodes and the scrap. The resulting heat quickly begins to melt the charge from the top down.

-

Refining: Once the metal is molten, the chemistry is adjusted. Materials like burnt lime are added to form a layer of slag on top of the molten metal. This slag acts as a purifying agent, drawing out impurities like sulfur and phosphorus from the steel.

Primary Applications and Materials

While versatile, the EAF is dominant in specific areas алюминий of metal production due to its unique characteristics.

Steel Scrap Recycling

The most significant application of the EAF is in "mini-mills" that focus on recycling. It allows producers to create new steel products directly from old cars, structural steel, and other discarded sources, forming a critical loop in the circular economy.

Specialized Metal and Alloy Production

Beyond carbon steel, EAFs are also used to produce cast-iron products, alloy steels, and stainless steels. Their precise temperature control and smaller batch sizes make them ideal for creating specialized metal grades.

Understanding the Trade-offs

The EAF is not a universal solution. Its advantages in flexibility and recycling come with specific operational considerations.

High Electricity Consumption

The primary drawback is its immense demand for electricity. An EAF requires a robust and reliable power grid, and electricity costs represent a major portion of its operating expense. The environmental footprint of the furnace is therefore directly tied to how that electricity is generated.

Dependence on Scrap Quality

The quality of the finished steel is heavily influenced by the quality of the incoming scrap. Contaminants in the scrap (like copper or tin) can be difficult to remove and may impact the final product's properties, requiring careful scrap selection and management.

Contrast with Traditional Furnaces

Unlike a Basic Oxygen Furnace (BOF), which primarily uses raw iron ore and produces its own heat through chemical reactions, an EAF is a recycler. A BOF is suited for massive, continuous production of virgin steel, while an EAF excels at smaller, more flexible batch production from scrap.

How to Apply This to Your Goal

Your choice of furnace technology depends entirely on your production strategy, available raw materials, and market focus.

- If your primary focus is recycling and market responsiveness: The EAF is the definitive choice for its ability to quickly and efficiently process scrap steel into new products.

- If your primary focus is high-volume production from raw materials: A Basic Oxygen Furnace is better suited for the large-scale conversion of iron ore into steel.

- If your primary focus is creating specialized alloys in smaller batches: The EAF provides the process control and flexibility needed for specialty steel and cast-iron manufacturing.

Ultimately, the electric arc furnace represents a pivotal technology that enables a more agile and sustainable approach to modern metal production.

Summary Table:

| Aspect | Electric Arc Furnace (EAF) | Basic Oxygen Furnace (BOF) |

|---|---|---|

| Primary Feedstock | Scrap Steel | Iron Ore |

| Key Advantage | Flexibility, Recycling, Smaller Batches | High-Volume, Continuous Production |

| Ideal For | Mini-Mills, Specialty Alloys, Market Responsiveness | Large-Scale Virgin Steel Production |

| Heat Source | Electric Arc | Chemical Reactions (Exothermic) |

Ready to enhance your lab's capabilities in materials testing and metal analysis? KINTEK specializes in providing high-quality lab equipment and consumables that support the research and quality control processes essential for modern metal production, including electric arc furnace operations. Our reliable tools help you achieve precise results. Contact our experts today to find the perfect solutions for your laboratory needs!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

People Also Ask

- What role does a quartz tube furnace play in hBN synthesis? Optimize Your Chemical Vapor Deposition Results

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?