At its core, a polishing glass base serves one critical function: it provides a perfectly flat, hard, and stable foundation for polishing materials, such as metallographic cloths. This absolute stability is essential for achieving a uniform and consistent finish across a sample's surface. Proper maintenance focuses on keeping the base perfectly clean, flat, and free from any physical damage that could compromise your results.

The integrity of your final polished surface is directly tied to the integrity of your glass base. Its role is not merely to hold the polishing cloth, but to guarantee the absolute planarity required for precision material analysis and preparation.

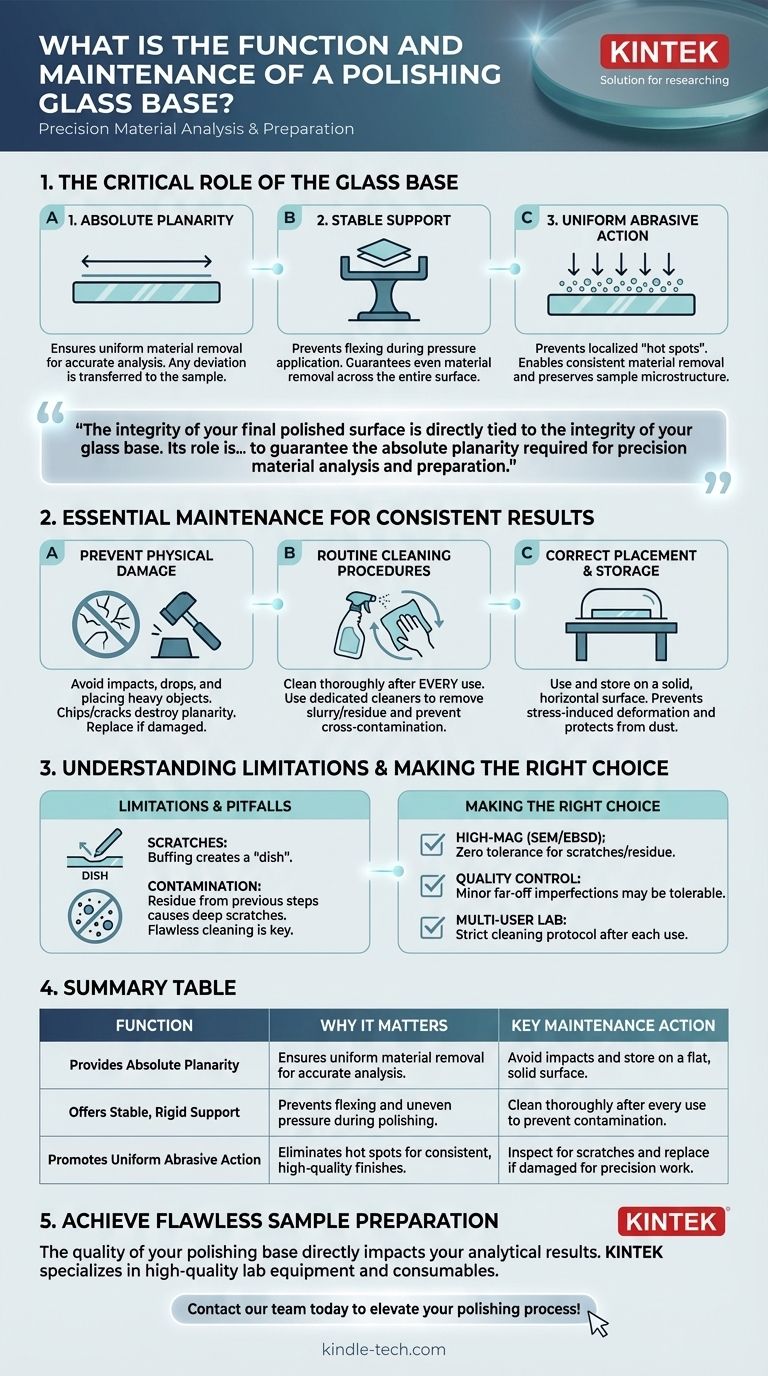

The Critical Role of the Glass Base

A polishing glass base is a simple tool, but its function is fundamental to achieving a high-quality, artifact-free surface. Its properties directly enable the core principles of lapping and polishing.

Ensuring Absolute Planarity

The primary purpose of the glass base is to provide a perfectly flat (planar) surface.

Any deviation, bow, or imperfection in the base will be directly transferred through the polishing cloth to the sample you are preparing. This creates an uneven surface, which can ruin metallographic analysis.

Providing Stable Support

The base must be hard and rigid.

During polishing, pressure is applied to the sample. The glass base prevents the polishing cloth and the underlying sample from flexing or deforming, ensuring material is removed evenly across the entire surface.

Promoting Uniform Abrasive Action

A flat, stable base ensures that the abrasive particles in a slurry or on a fixed-abrasive cloth are applied with consistent pressure.

This prevents localized "hot spots" of aggressive polishing and ensures a uniform material removal rate, which is critical for preserving the true microstructure of a sample.

Essential Maintenance for Consistent Results

Maintaining your glass base is not just about cleanliness; it is about preserving the geometric perfection required for repeatable, high-quality outcomes.

Preventing Physical Damage

This is the most critical aspect of maintenance. You must avoid impacts, drops, and placing heavy objects on the glass.

A chip, crack, or deep scratch renders the base useless for precision work because it destroys the perfect planarity in that area.

Routine Cleaning Procedures

The base must be cleaned thoroughly after every use.

Use a dedicated glass cleaner or appropriate solvent to remove all slurry, lubricant, and debris. This prevents cross-contamination between different abrasive grit sizes, which is a common source of rogue scratches in a final polish.

Correct Placement and Storage

Always use and store the glass base on a solid, horizontal surface.

This prevents stress from being induced into the glass, which could theoretically cause deformation over long periods. Storing it flat and covered also protects the surface from dust and accidental damage.

Understanding the Limitations and Pitfalls

While robust, a glass base is not immune to issues that can compromise your work. Awareness of these limitations is key to avoiding failed polishing attempts.

The Problem with Scratches

Minor surface scratches can sometimes be buffed out with a fine polishing paste, but this should be considered a last resort.

The process of buffing a scratch inevitably creates a subtle low spot, or "dish," in the surface. While invisible to the eye, this deviation from planarity can be detrimental to high-end applications like preparing samples for Electron Backscatter Diffraction (EBSD).

Contamination Is a Critical Failure

Residue from a previous, coarser polishing step is the primary cause of unexpected deep scratches during fine polishing.

Your cleaning protocol must be flawless. A base that is not perfectly clean will transfer old, larger abrasive particles onto your fine polishing cloth and ruin your sample.

Making the Right Choice for Your Goal

To ensure your glass base supports, rather than hinders, your work, your maintenance standards should align with your analytical objectives.

- If your primary focus is high-magnification analysis (e.g., SEM, EBSD): Treat the glass base as a precision optical component; any scratch or residue is unacceptable and warrants immediate replacement.

- If your primary focus is routine quality control or visual inspection: Regular cleaning and careful handling are sufficient, and minor surface imperfections located far from the primary working area may be tolerable.

- If your primary focus is maintaining a lab for multiple users: Implement and enforce a strict cleaning protocol after each use to prevent cross-contamination between different projects and materials.

Ultimately, treating your polishing base with meticulous care is a direct investment in the quality and reliability of your results.

Summary Table:

| Function | Why It Matters | Key Maintenance Action |

|---|---|---|

| Provides Absolute Planarity | Ensures uniform material removal for accurate analysis. | Avoid impacts and store on a flat, solid surface. |

| Offers Stable, Rigid Support | Prevents flexing and uneven pressure during polishing. | Clean thoroughly after every use to prevent contamination. |

| Promotes Uniform Abrasive Action | Eliminates hot spots for consistent, high-quality finishes. | Inspect for scratches and replace if damaged for precision work. |

Achieve flawless sample preparation with the right foundation. The quality of your polishing base directly impacts your analytical results. KINTEK specializes in high-quality lab equipment and consumables for all your material preparation needs. Ensure your lab's success with reliable tools and expert support. Contact our team today to discuss your specific requirements and elevate your polishing process!

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Polygon Press Mold for Lab

- High Purity Gold Platinum Copper Iron Metal Sheets

- Three-dimensional electromagnetic sieving instrument

- Small Lab Rubber Calendering Machine

People Also Ask

- How should an RVC sheet be handled and set up during an experiment? Ensure Precision and Data Integrity

- What is the general procedure and what precautions should be taken during the polishing process? Achieve a Flawless Electrode Finish

- What is the process of mounting in metallurgy? A Guide to Perfect Specimen Preparation

- What is the purpose of using epoxy resin and laboratory mounting equipment? Precision in U71Mn Weld Area Analysis

- What role do laboratory grinding and polishing systems play in nitriding? Ensure Superior Mirror-Finish & Ion Penetration