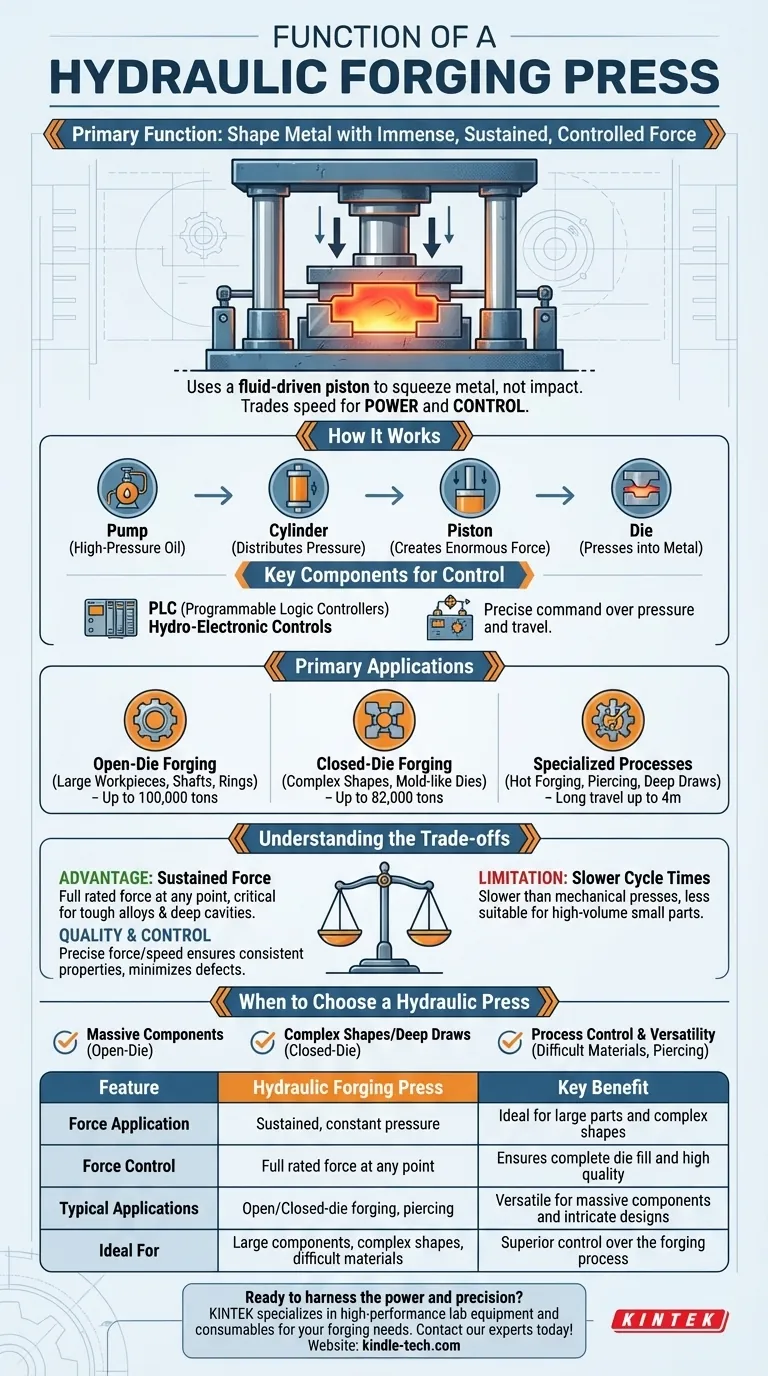

The primary function of a hydraulic forging press is to shape metal by applying immense, sustained, and precisely controlled force through a fluid-driven piston. Unlike hammer-based forging, which relies on impact, a hydraulic press uses constant pressure to squeeze the workpiece into its desired shape, making it ideal for large components and complex designs.

At its core, a hydraulic forging press trades speed for power and control. It excels at delivering massive, constant force throughout its entire stroke, enabling the formation of large or intricate metal parts that are impossible to create with other methods.

How a Hydraulic Press Generates Force

A hydraulic forging press operates on a straightforward yet powerful principle of fluid mechanics, which is then managed by sophisticated control systems to ensure precision.

The Core Principle: Fluid Pressure

The machine uses a large cylinder containing a piston. High-pressure hydraulic oil is pumped into this cylinder, distributing pressure evenly across the face of the piston. This pressure creates an enormous force that extends the piston and its attached die, pressing it into the metal workpiece with controlled power.

Key Components for Control

Modern presses are more than just raw power. They incorporate advanced systems to manage the forging process, including Programmable Logic Controllers (PLCs) and hydro-electronic controls for precise command over pressure and travel distance. A centralized lubrication system and water-cooled heat exchangers ensure the machine can operate reliably under extreme loads.

Primary Applications in Forging

The unique characteristics of hydraulic presses make them suitable for a wide range of forging operations, from creating massive industrial components to intricate, high-strength parts.

Open-Die Forging

For extremely large workpieces, open-die forging is used. In this process, the metal is not completely enclosed by the die. Presses for this application can range from 200 to over 100,000 tons of force, used to create shafts, rings, and other large-scale industrial components.

Closed-Die Forging

In closed-die, or impression-die forging, the metal is placed in a die that resembles a mold. The press then squeezes the material, forcing it to fill the entire cavity. This method is used for more complex shapes and can be handled by presses with capacities up to 82,000 tons.

Specialized Processes

The long working travel distances (up to 4 meters) and high forces make these presses perfect for specialized tasks. This includes hot forging large billets, piercing operations to create hollows, and the partial forging of components like fittings and thick-walled pipes.

Understanding the Trade-offs

Choosing a hydraulic press involves understanding its fundamental advantages and limitations compared to other forging equipment, such as mechanical presses.

The Defining Advantage: Sustained Force

The single greatest advantage of a hydraulic press is its ability to deliver its full rated force at any point in its stroke. This sustained pressure is critical for shaping tough alloys or creating parts with deep cavities, ensuring the metal flows completely into the die.

The Inherent Limitation: Slower Cycle Times

The trade-off for this immense, controlled power is speed. The process of pumping fluid to build pressure is inherently slower than the crank-driven action of a mechanical press. This makes hydraulic presses less suitable for high-volume production of smaller parts.

The Focus on Quality and Control

What a hydraulic press lacks in speed, it makes up for in precision. The ability to precisely control the force, speed, and duration of the press stroke ensures the highest quality for processed products, minimizing defects and achieving consistent metallurgical properties.

When to Choose a Hydraulic Forging Press

Selecting the right forging equipment depends entirely on the specific requirements of the component being produced.

- If your primary focus is shaping massive components: A hydraulic press is the definitive choice for large-scale open-die work where sheer, sustained force is paramount.

- If your primary focus is creating complex shapes with deep draws: The long, constant pressure stroke of a hydraulic press is ideal for closed-die applications that require the metal to flow into intricate cavities.

- If your primary focus is process control and versatility: A hydraulic press offers unparalleled control over forging variables, making it perfect for working with difficult materials or performing specialized operations like piercing.

Ultimately, understanding the principle of controlled hydraulic force is the key to leveraging this powerful technology for the most demanding metal forming challenges.

Summary Table:

| Feature | Hydraulic Forging Press | Key Benefit |

|---|---|---|

| Force Application | Sustained, constant pressure | Ideal for large parts and complex shapes |

| Force Control | Full rated force at any point in the stroke | Ensures complete die fill and high-quality results |

| Typical Applications | Open-die forging, closed-die forging, piercing | Versatile for massive components and intricate designs |

| Ideal For | Large components, complex shapes, difficult materials | Superior control over the forging process |

Ready to harness the power and precision of a hydraulic forging press for your lab or production facility? KINTEK specializes in high-performance lab equipment and consumables, serving the precise needs of laboratories and industrial forging operations. Whether you are working on large-scale industrial components or intricate, high-strength parts, our expertise can help you achieve superior results. Contact our experts today to discuss how our solutions can enhance your metal shaping capabilities!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.