A muffle is a specialized enclosure placed inside a furnace that acts as a protective barrier for the material being heated. Its primary function is to isolate the workload from the direct heat source and its byproducts, which prevents contamination and ensures highly uniform heating. While it does contribute to temperature retention, its main purpose is process control and purity.

The core purpose of a muffle is not just general insulation, but process isolation. It creates a controlled, clean, and uniform heating environment by separating the material you are heating from the furnace's raw heating elements.

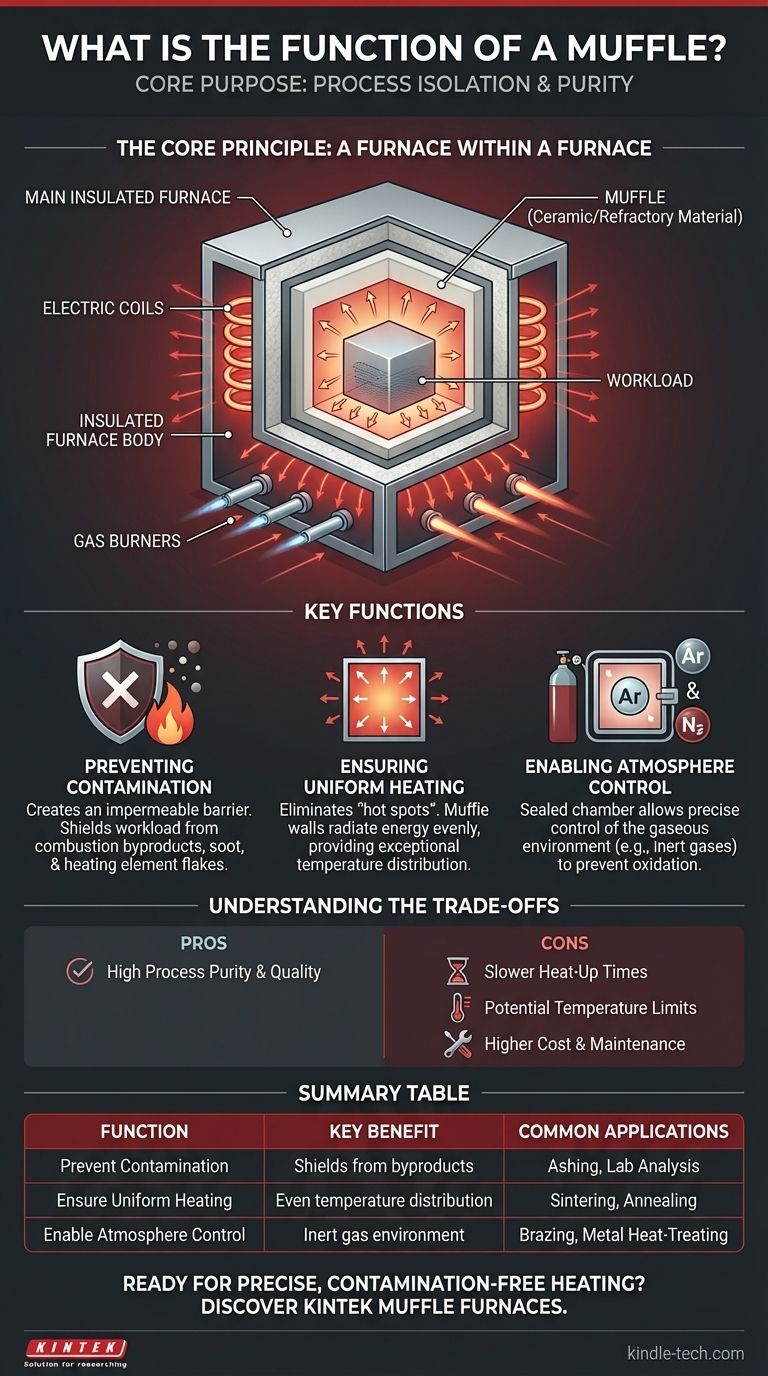

The Core Principle: A Furnace Within a Furnace

A muffle furnace operates on a simple but effective principle. Understanding its physical arrangement is key to grasping its function.

What a Muffle Is

A muffle is essentially a box, tube, or chamber made from a high-temperature-resistant (refractory) material, such as a ceramic like mullite or alumina.

This chamber is placed inside the main insulated body of a furnace. The workload—the item or material to be heated—is placed inside the muffle.

How It Works

The furnace's heating elements (whether electric coils or gas burners) are located outside the muffle. They heat the muffle's exterior walls to the desired temperature.

The muffle then absorbs this energy and radiates it evenly from all its interior surfaces onto the workload inside. This indirect heating is the critical feature.

Key Functions of a Muffle

Using a muffle provides three distinct advantages that are crucial for high-precision thermal processes like ashing, sintering, annealing, or laboratory analysis.

Preventing Contamination

The muffle creates an impermeable physical barrier between the heat source and the workload.

This is vital for protecting samples from contaminants like combustion byproducts (soot, gases) in a fuel-fired furnace or from small particles that can flake off electric heating elements as they age.

Ensuring Uniform Heating

Direct radiation from glowing-hot heating elements can create "hot spots" on the workload. The muffle eliminates this.

By absorbing and re-radiating the energy, the muffle's walls become a single, large, uniform heating surface. This provides exceptionally even temperature distribution, which is critical for processes where precise temperature control is paramount.

Enabling Atmosphere Control

Because the muffle is a sealed chamber, it allows for precise control over the gaseous environment around the workload.

Special atmospheres, such as inert gases like argon or nitrogen, can be pumped in to prevent oxidation. This is essential for applications like brazing or heat-treating sensitive metals.

Understanding the Trade-offs

While powerful, the muffle design is not without its drawbacks. It represents a deliberate choice to prioritize control over other factors.

Slower Heat-Up Times

The muffle itself has significant thermal mass. The furnace must first heat the entire muffle before the workload inside can reach the target temperature. This can result in longer process cycle times compared to a non-muffle furnace.

Potential Temperature Limits

The maximum operating temperature of the furnace is often limited by the material of the muffle itself. High-performance ceramics are expensive, and all have a point of failure.

Cost and Maintenance

Muffles are components that are subject to extreme thermal stress and cycling. Over time, they can crack and will eventually need to be replaced, adding to the operational cost of the furnace.

When is a Muffle Necessary?

Choosing a muffle furnace depends entirely on the requirements of your specific process.

- If your primary focus is process purity: A muffle is essential to shield your material from contamination from the heat source.

- If your primary focus is temperature uniformity: A muffle provides superior even heating compared to direct element radiation, which is critical for sensitive materials.

- If your primary focus is atmosphere control: A muffle is the only practical way to maintain a specialized gas environment separate from the main furnace chamber.

- If your primary focus is raw heating speed: A simpler furnace without a muffle may be faster and more cost-effective, provided that contamination and perfect uniformity are not concerns.

Ultimately, using a muffle is a decision to prioritize process control and the quality of your final result.

Summary Table:

| Function | Key Benefit | Common Applications |

|---|---|---|

| Prevent Contamination | Shields materials from heat source byproducts (soot, flakes) | Ashing, laboratory analysis, sample preparation |

| Ensure Uniform Heating | Creates even temperature distribution by acting as a radiant surface | Sintering, annealing, heat treatment |

| Enable Atmosphere Control | Allows use of inert gases (e.g., argon, nitrogen) to prevent oxidation | Brazing, metal heat-treating, controlled environment processes |

Ready to achieve precise, contamination-free heating in your lab?

At KINTEK, we specialize in high-performance muffle furnaces designed for laboratory environments where process purity and temperature uniformity are critical. Whether you're working on ashing, sintering, or heat treatment, our equipment ensures reliable results with superior control.

Contact us today to discuss your specific needs and discover how our lab equipment solutions can enhance your thermal processes!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a high-temperature muffle furnace play in the measurement of ash content in biomass samples? Accurate Analysis Guide

- What is the purpose of using a high-temperature furnace for SiC powder pre-treatment? Enhance Composite Bond Strength

- How does a high-temperature muffle furnace facilitate the control of crystalline phase transformations in TiO2?

- Why do we determine ash content in coal? Uncover Its True Energy Value & Avoid Costly Downtime

- What is muffle furnace working principle and application? Achieve Contamination-Free High-Temperature Processing

- What role does a muffle furnace play in LATP synthesis? Optimize Ionic Conductivity for Ceramic Electrolytes

- How hot is a muffle furnace in Celsius? A Guide to Temperature Ranges from 800°C to 1800°C

- What does ash represent in a sample? A Key Indicator of Mineral Content and Purity