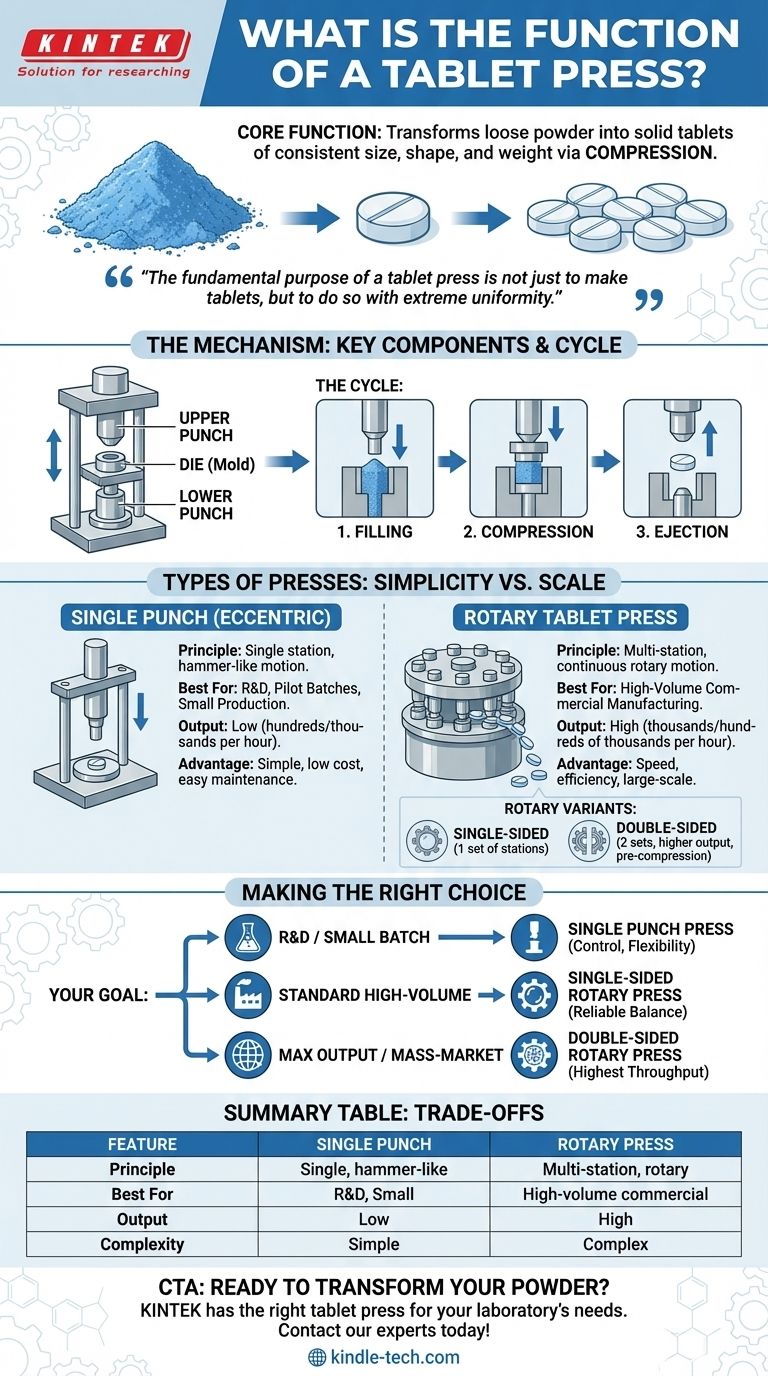

At its core, a tablet press is a mechanical device that transforms loose powder into solid tablets of a consistent size, shape, and weight. This is accomplished through the principle of compression, where precisely engineered tooling applies immense force to the powder within a confined cavity. Its applications are vast, ranging from manufacturing pharmaceuticals and nutraceuticals to creating cleaning products and industrial pellets.

The fundamental purpose of a tablet press is not just to make tablets, but to do so with extreme uniformity. It uses a system of punches and dies to apply controlled pressure, ensuring every tablet meets precise specifications for weight, thickness, and hardness.

The Core Principle of Tablet Compression

Understanding how a tablet press works requires looking at its three essential components and the cycle they perform. This mechanical process is the foundation of tablet manufacturing across all industries.

The Key Components: Punches and a Die

A tablet is formed at a single "station," which consists of three parts.

The die is the mold that defines the final shape and diameter of the tablet. Powdered material is fed into this cavity.

The upper and lower punches are the tools that compress the powder within the die. They move in a coordinated sequence to press the material and then eject the finished tablet.

The Compression Cycle Explained

The tableting process follows a precise, multi-step cycle that is repeated rapidly.

- Filling: The lower punch drops within the die, creating a cavity that is then filled with the powdered formulation.

- Compression: The upper punch descends into the die, applying high force to the powder. This pressure compacts the loose particles into a solid tablet.

- Ejection: The upper punch retracts, and the lower punch rises, pushing the finished tablet out of the die cavity.

Achieving Critical Uniformity

The mechanical precision of the press ensures this cycle produces nearly identical tablets. The volume of the die cavity is fixed, ensuring consistent weight, while the force applied by the punches determines the tablet's hardness and thickness.

Types of Tablet Presses and Their Applications

While the principle is the same, tablet presses are designed for different scales of production. The primary distinction is between single-station and multi-station rotary designs.

Single Punch (Eccentric) Press

A single punch press uses one station of tooling (one die and one pair of punches). The upper punch moves up and down in a hammer-like motion to compress the powder.

This design is simpler and ideal for research and development, pilot batches, or small-scale production where output volume is not the primary concern.

Rotary Tablet Press

A rotary tablet press is built for high-volume manufacturing. It features a rotating turret that holds numerous dies and punch pairs.

As the turret spins, each station moves sequentially through the filling, compression, and ejection phases. This continuous motion allows for the production of thousands, or even hundreds of thousands, of tablets per hour.

Single-Sided vs. Double-Sided Rotary Presses

Rotary presses are further divided by their output capacity. A single-sided press has one set of filling and compression stations.

A double-sided press is essentially two presses in one, with two feeding and compression points on the turret. These machines are used for massive production runs and often include a pre-compression stage to remove trapped air from the powder, resulting in a higher quality tablet.

Understanding the Trade-offs: Simplicity vs. Scale

Choosing a tablet press involves a clear trade-off between the complexity of the machine and its production output. This decision directly impacts cost, maintenance, and operational flexibility.

The Simplicity of Single Punch Presses

The main advantage of a single punch press is its simplicity. It is less expensive to purchase, easier to operate and maintain, and faster to clean and change over for different products.

However, its output is dramatically lower than a rotary press, making it completely unsuitable for commercial-scale manufacturing.

The Power of Rotary Presses

The overwhelming advantage of a rotary press is its speed and efficiency for large-scale production. The continuous, multi-station design provides an output that is orders of magnitude higher than a single punch press.

The downside is increased complexity, higher initial investment, and more involved maintenance and cleaning procedures.

Making the Right Choice for Your Goal

The function you require from a tablet press depends entirely on your production objective. The choice between a simple or a high-output machine should be guided by your specific application.

- If your primary focus is research and development or small-batch production: A single punch press offers the necessary control, flexibility, and cost-effectiveness for formulation testing.

- If your primary focus is standard, high-volume manufacturing: A single-sided rotary press is the industry workhorse, providing a reliable balance of speed and efficiency.

- If your primary focus is maximizing output for mass-market products: A double-sided rotary press delivers the highest possible throughput and is the standard for large-scale pharmaceutical and industrial operations.

Ultimately, understanding the mechanics of tablet compression empowers you to select the precise tool needed to turn raw powder into a uniform, finished product.

Summary Table:

| Feature | Single Punch Press | Rotary Press |

|---|---|---|

| Principle | Single station, hammer-like compression | Multi-station, continuous rotary motion |

| Best For | R&D, small batches, pilot production | High-volume commercial manufacturing |

| Output | Low (hundreds to thousands per hour) | High (thousands to hundreds of thousands per hour) |

| Complexity | Simple, easy to maintain | Complex, higher maintenance |

Ready to transform your powder into precise tablets? Whether you're in R&D or full-scale production, KINTEK has the right tablet press for your laboratory's needs. Our expertise in lab equipment ensures you get a machine that delivers the consistency and output you require. Contact our experts today to find your perfect solution!

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What is the difference between single punch and rotary tablet press? Choose the Right Machine for Your Lab or Production

- What are the different types of pelletizers? A Guide to Choosing the Right Machine for Your Material

- What is the process of pelleting biomass? Transform Raw Biomass into High-Value, Energy-Dense Fuel

- What is a press tab pill? The Complete Guide to Pressed Tablets

- What is the principle of a single punch tablet press machine? A Guide to Precision Lab-Scale Production

- What do you press pills with? The Essential Guide to Tablet Press Machines

- Are wood pellets made from sawdust? Unlock the Secret to High-Performance Fuel

- What are the different types of pellet mill die? Flat Die vs. Ring Die Explained