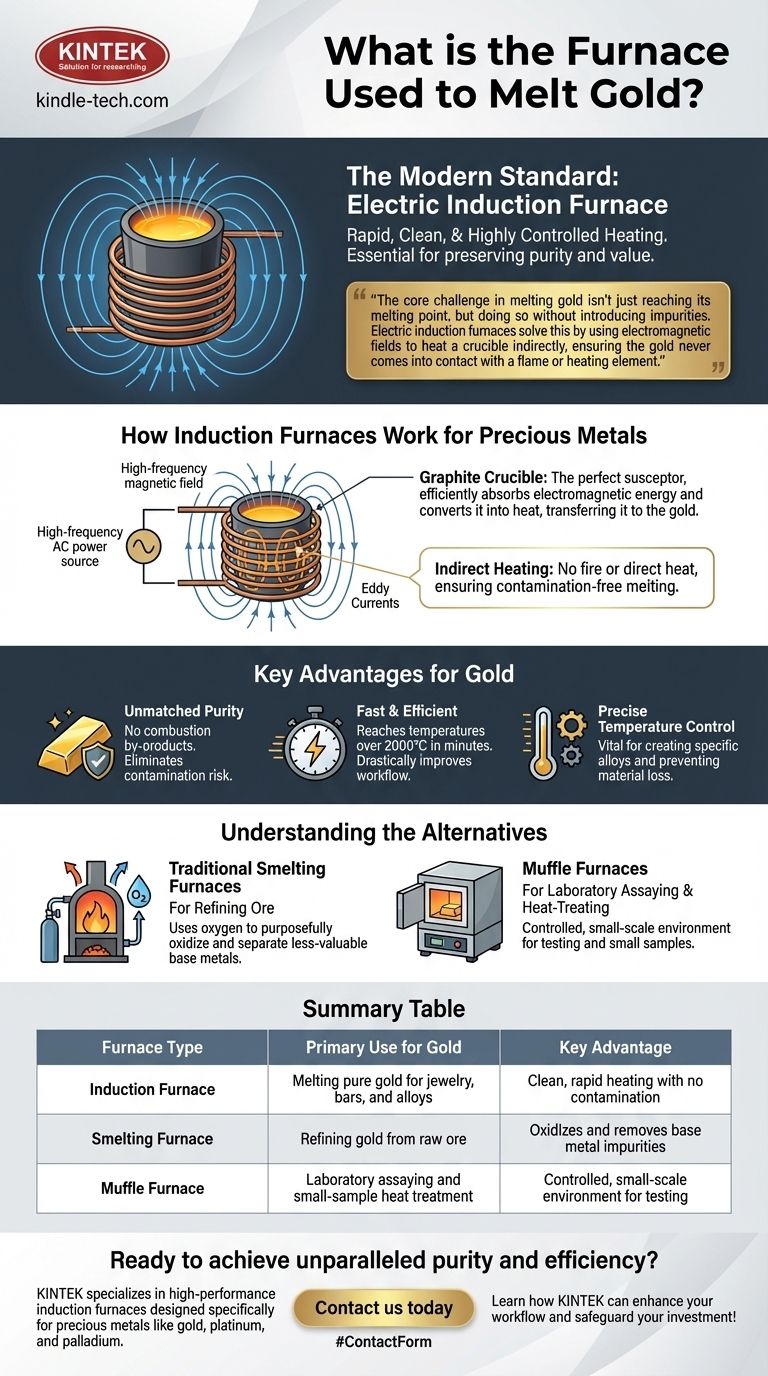

For melting gold, the modern standard is the electric induction furnace. This technology is preferred because it provides rapid, clean, and highly controlled heating, which is essential for preserving the purity and value of precious metals.

The core challenge in melting gold isn't just reaching its melting point, but doing so without introducing impurities. Electric induction furnaces solve this by using electromagnetic fields to heat a crucible indirectly, ensuring the gold never comes into contact with a flame or heating element.

How Induction Furnaces Work for Precious Metals

An induction furnace doesn't use fire or direct heat. Instead, it leverages a powerful principle of physics to generate heat precisely where it's needed.

The Principle of Electromagnetic Induction

The furnace creates a powerful, high-frequency alternating magnetic field using a copper coil. This field passes through a graphite crucible placed inside the coil.

The magnetic field induces strong electrical currents, known as eddy currents, within the graphite. The graphite's natural resistance to these currents causes it to heat up rapidly and intensely.

The Role of the Graphite Crucible

Graphite is the ideal material for this process. It is a perfect susceptor, meaning it efficiently absorbs the electromagnetic energy and converts it into heat.

This heat is then transferred conductively to the gold inside the crucible, causing it to melt in a very clean and contained environment.

Key Advantages for Gold

Using an induction furnace provides three critical benefits when working with gold and other precious metals like platinum or palladium.

First, it offers unmatched purity. Since there are no combustion by-products like gas or ash, the risk of contaminating the valuable metal is eliminated.

Second, it is incredibly fast and efficient. High-powered units can bring metals to temperatures over 2000°C in just a few minutes, drastically improving workflow.

Finally, it allows for precise temperature control, which is vital for creating specific alloys or preventing the loss of valuable material through overheating.

Understanding the Alternatives

While induction is the primary choice for melting pure gold, other furnace types exist for different stages of metal processing.

Traditional Smelting Furnaces

Furnaces equipped with burners and lances that create an oxygen-rich atmosphere are used for smelting, not just melting.

This process is for refining ore. The goal is to heat the raw material and use oxygen to purposefully oxidize and separate out less-valuable base metals from the gold.

Muffle Furnaces

A muffle furnace is a smaller, box-type furnace typically used in laboratories.

While they can reach high temperatures, their small size makes them better suited for heat-treating metal parts to improve strength or for assaying (testing) small samples, not for melting bulk quantities.

Making the Right Choice for Your Goal

The correct furnace depends entirely on the metallurgical task you need to accomplish.

- If your primary focus is melting pure gold for jewelry, investment bars, or alloying: An electric induction furnace is the industry standard for its cleanliness, speed, and control.

- If your primary focus is extracting gold from raw ore: A smelting furnace designed for oxidation and the removal of impurities is the necessary tool for refining.

- If your primary focus is laboratory analysis or heat-treating small parts: A muffle furnace provides a controlled, small-scale environment for testing purposes.

Ultimately, choosing the right heating technology is fundamental to achieving the desired purity, efficiency, and final quality of the metal.

Summary Table:

| Furnace Type | Primary Use for Gold | Key Advantage |

|---|---|---|

| Induction Furnace | Melting pure gold for jewelry, bars, and alloys | Clean, rapid heating with no contamination |

| Smelting Furnace | Refining gold from raw ore | Oxidizes and removes base metal impurities |

| Muffle Furnace | Laboratory assaying and small-sample heat treatment | Controlled, small-scale environment for testing |

Ready to achieve unparalleled purity and efficiency in your gold melting process?

KINTEK specializes in high-performance lab equipment, including state-of-the-art induction furnaces designed specifically for precious metals like gold, platinum, and palladium. Our solutions ensure rapid, contamination-free melting with precise temperature control to protect your valuable materials.

Whether you're crafting jewelry, creating investment bars, or developing specialized alloys, KINTEK has the right equipment to meet your laboratory's exact needs.

Contact us today to learn how our gold melting furnaces can enhance your workflow and safeguard your investment!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Arc Induction Melting Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere

- Why use a tube furnace? Achieve Superior Temperature Uniformity and Atmosphere Control

- How does a tube furnace work? Master Precise Thermal and Atmospheric Control

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab