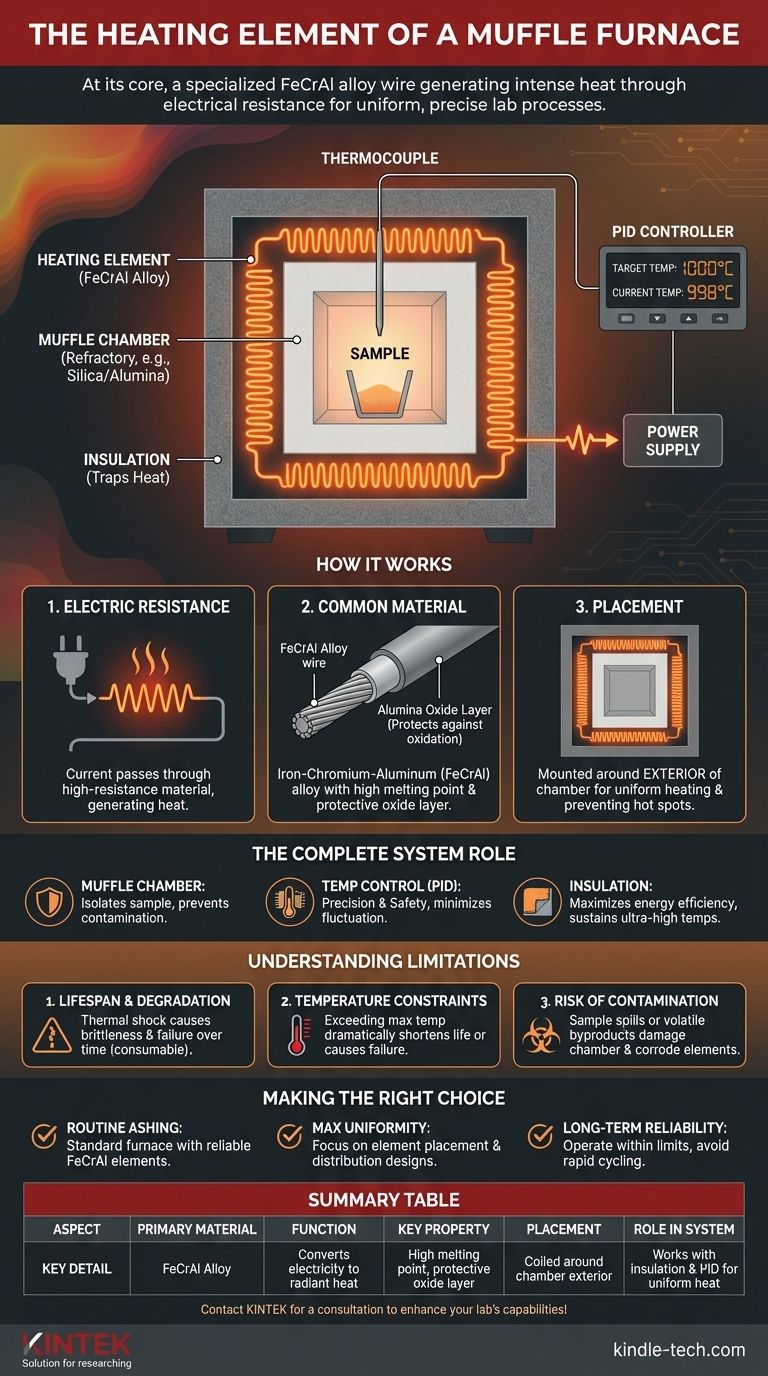

At its core, the heating element in a muffle furnace is a specialized wire or rod that generates intense heat through electrical resistance. These elements are most commonly made from an iron-chromium-aluminum (FeCrAl) alloy, designed to withstand extremely high temperatures and resist oxidation. Their function is to convert electrical energy into the radiant heat needed to bring the furnace's inner chamber to its target temperature.

The heating element is the engine of the furnace, but its true value comes from its integration within the system. The "muffle," or insulated chamber, separates your sample from the raw heat source, ensuring clean, uniform, and precisely controlled heating—which is the fundamental purpose of the furnace.

How the Heating Element Works

A muffle furnace's ability to reach temperatures exceeding 1000°C begins with a simple principle: converting electricity into heat. The heating element is the component engineered to do this efficiently and reliably.

The Principle of Electric Resistance

Heating elements are made from materials with high electrical resistance. When a controlled electric current from the power supply is passed through them, this resistance causes the elements to heat up and glow, radiating thermal energy into the furnace chamber.

Common Element Materials

The most prevalent material for these elements is an iron-chromium-aluminum (FeCrAl) alloy, sometimes known by trade names like Kanthal. This material is chosen for its critical properties: a very high melting point and the ability to form a protective layer of aluminum oxide on its surface, which prevents it from degrading at extreme temperatures.

Placement for Uniform Heating

The elements are not placed inside the chamber with your sample. Instead, they are typically coiled and mounted around the exterior of the inner chamber, often embedded within the refractory insulation. This ensures that heat is radiated evenly into the chamber, preventing "hot spots" and providing uniform temperature for the material being heated.

The Element's Role in the Complete System

The heating element does not work in isolation. It is a critical part of a coordinated system where each component has a specific job.

The Muffle Chamber: A Protective Barrier

The "muffle" itself is the sealed inner chamber made of refractory materials like silica and alumina. Its primary purpose is to isolate the sample from the heating elements. This separation prevents any potential contamination from the elements and ensures the sample is heated purely by radiation in a clean environment.

The Temperature Control System: Precision and Safety

A sophisticated control system manages the heating element. A thermocouple inside the chamber measures the real-time temperature and sends this data to a PID controller. The controller then precisely pulses power to the heating elements, turning them on and off rapidly to maintain the exact setpoint temperature with minimal fluctuation.

Insulation: Maximizing Efficiency

High-quality insulation surrounds the muffle and its heating elements. This material traps the immense heat generated by the elements, preventing it from escaping. This not only makes the furnace highly energy-efficient but is also what allows it to reach and sustain ultra-high temperatures.

Understanding the Limitations

While robust, heating elements are the primary consumable component in a muffle furnace and have operational limits.

Element Lifespan and Degradation

Heating elements degrade over time. The constant cycle of extreme heating and cooling (thermal shock) eventually makes the alloy brittle, leading to failure. This is normal wear and tear, and the elements are designed to be replaceable.

Temperature Constraints

The specific alloy used for the heating element dictates the furnace's maximum achievable temperature. Exceeding this recommended temperature can dramatically shorten the element's life or cause immediate failure.

Risk of Contamination

Although the muffle protects the sample from the element, it also protects the element from the sample. Spills or volatile byproducts from a sample can damage the refractory chamber. If these contaminants reach the heating elements, they can cause corrosion and lead to premature failure.

Making the Right Choice for Your Goal

Understanding the heating element's role helps you use your furnace more effectively and troubleshoot issues.

- If your primary focus is routine ashing or heat treatment: A standard furnace with FeCrAl elements is the industry workhorse, providing reliable performance and cost-effectiveness.

- If your primary focus is maximum temperature uniformity: Pay attention to furnace designs that emphasize the placement and distribution of heating elements around the chamber for the most even heating possible.

- If your primary focus is long-term reliability: Operate the furnace within its specified temperature limits and avoid rapid, unnecessary temperature cycling to maximize the lifespan of the heating elements.

By understanding the heating element as the core of a sophisticated system, you can ensure precise results and maintain your equipment for optimal performance.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Material | Iron-Chromium-Aluminum (FeCrAl) Alloy |

| Function | Converts electrical energy into radiant heat via resistance |

| Key Property | High melting point & forms protective oxide layer |

| Placement | Coiled around the exterior of the inner muffle chamber |

| Role in System | Works with insulation and PID control for uniform heating |

Achieve precise, contamination-free heating for your lab processes. The right muffle furnace is critical for applications like ashing, heat treatment, and materials testing. KINTEK specializes in high-performance lab furnaces with robust heating elements and advanced control systems designed for reliability and accuracy.

Let our experts help you select the perfect furnace for your specific temperature and uniformity requirements.

Contact KINTEK today for a consultation to enhance your lab's capabilities!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the introduction of muffle furnace? A Guide to High-Temperature, Contamination-Free Heating

- How do you check the temperature of a muffle furnace? A Guide to Precise Monitoring

- Which type of material is used for overheating protection in muffle furnace? A Dual-Layer Safety System Explained

- What 5 safety precautions should be taken when heating anything in the lab? Essential Rules for Lab Safety

- What is the application of a muffle furnace? Achieve Contamination-Free High-Temperature Processing