Contrary to its modern-sounding name, the core principle behind Spark Plasma Sintering (SPS) is not a recent discovery. The technology has a long history stretching back to the early 20th century, but it was the development of advanced power electronics and control systems in Japan during the 1980s and 1990s that led to its commercialization and widespread adoption under the "SPS" banner.

The history of Spark Plasma Sintering is one of technological evolution and rebranding. The fundamental concept of using an electric current to simultaneously heat and press a powder is nearly a century old, but modern SPS represents a highly refined and commercially successful implementation of this principle, despite ongoing debate about the name's scientific accuracy.

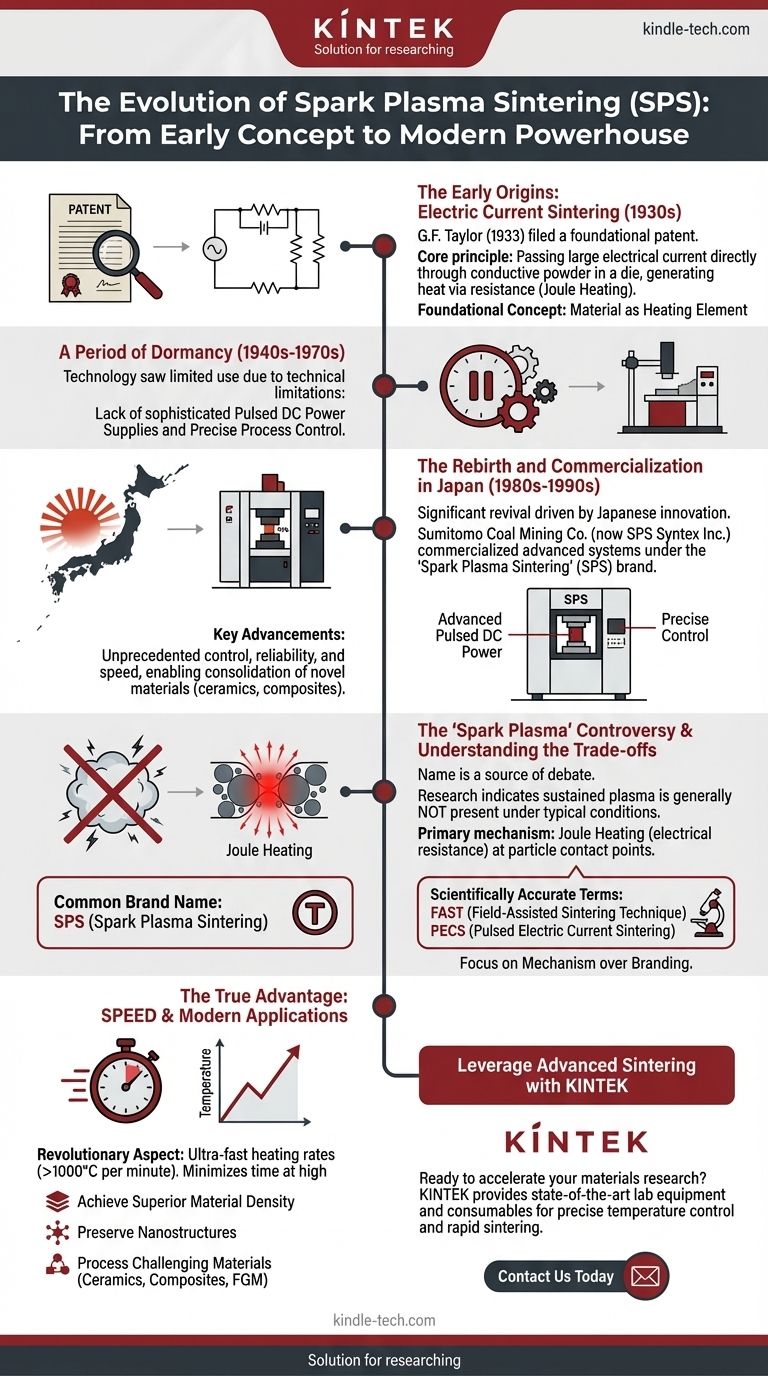

The Early Origins: Electric Current Sintering

The idea of using an electric current to consolidate powders has been around for much longer than the "SPS" trademark. Its origins lie in what is more broadly and accurately known as Field-Assisted Sintering Technique (FAST).

The Foundational Patent

The earliest work dates back to the 1930s. A key patent by G. F. Taylor in 1933 described a method for passing a large electrical current directly through a die containing a conductive powder, generating rapid heat through electrical resistance.

This foundational concept—using the material itself (and its contact points) as the heating element—is the core principle that underpins modern SPS.

A Period of Dormancy

Despite this early patent, the technology saw limited use for several decades. The primary obstacles were technical: the lack of sophisticated pulsed DC power supplies and precise process control systems needed to manage the extremely high heating rates without damaging the sample or equipment.

The Rebirth and Commercialization in Japan

The technology experienced a significant revival in the late 20th century, primarily driven by innovation in Japan. This is the era that gave birth to the name "Spark Plasma Sintering."

Sumitomo and the "SPS" Brand

In the late 1980s and early 1990s, Japanese companies like Sumitomo Coal Mining Co. (now SPS Syntex Inc.) developed and commercialized advanced systems based on this principle. They branded their specific process and equipment as "Spark Plasma Sintering" (SPS).

This commercialization was the turning point. The new machines offered unprecedented control, reliability, and speed, enabling researchers to consolidate novel materials like ceramics, composites, and functionally graded materials that were difficult to process using conventional furnaces.

The "Spark Plasma" Controversy

The name itself has been a source of significant scientific debate. The term suggests that a spark or a plasma is generated between the powder particles, which is thought to clean particle surfaces and enhance sintering.

However, a large body of research indicates that a sustained plasma is generally not present under typical SPS conditions. The primary heating mechanism is understood to be Joule heating (electrical resistance), concentrated at the contact points between particles.

Understanding the Trade-offs and Misconceptions

Understanding the history clarifies common points of confusion about the technology and its name. The key is to separate the physical mechanism from the commercial branding.

Name vs. Mechanism

Many in the academic community prefer more descriptive terms like Field-Assisted Sintering Technique (FAST) or Pulsed Electric Current Sintering (PECS). These names accurately describe the process without making a claim about the presence of plasma.

"SPS" is best understood as a trademark for a highly successful type of FAST/PECS equipment.

The True Advantage: Speed

The revolutionary aspect of the technology, both in its early conception and modern form, is speed. By using the sample as the heating element, heating rates can exceed 1000°C per minute.

This ultra-fast heating minimizes the time the material spends at high temperatures, which is crucial for preventing unwanted grain growth. This allows for the creation of dense, nanostructured materials with superior mechanical properties.

How This History Informs Modern Use

Understanding the journey from a 1930s patent to a modern commercial process provides critical context for anyone using or evaluating this technology.

- If your primary focus is research: Prioritize understanding the underlying mechanism as a form of FAST/PECS. This allows you to better control process parameters beyond the presets of a commercial machine.

- If your primary focus is material production: Recognize that "SPS" represents a mature, reliable, and highly capable technology, not an experimental one, due to decades of refinement.

- If you are communicating your work: Be aware that while "SPS" is a common term, using "FAST" or "PECS" can be more scientifically precise and is often preferred in academic literature.

Knowing that SPS is built on a long-established foundation gives you the confidence to leverage its powerful capabilities for advanced materials development.

Summary Table:

| Era | Key Development | Significance |

|---|---|---|

| 1930s | G.F. Taylor's foundational patent for electric current sintering | Established core principle of using powder as heating element |

| 1980s-1990s | Japanese commercialization by Sumitomo (SPS brand) | Introduced advanced pulsed DC power supplies and process control |

| Modern Day | Widespread adoption as FAST/PECS technology | Enables rapid sintering of advanced materials with minimal grain growth |

Ready to leverage advanced sintering technology for your materials research?

At KINTEK, we specialize in providing state-of-the-art lab equipment and consumables for materials science applications. Our expertise in sintering technologies can help you:

- Achieve superior material density with precise temperature control

- Preserve nanostructures through rapid heating rates up to 1000°C per minute

- Process challenging materials including ceramics, composites, and functionally graded materials

Whether you're conducting fundamental research or scaling up material production, our team can provide the right equipment and support for your sintering needs.

Contact us today to discuss how our sintering solutions can accelerate your materials development!

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the name of the industrial furnace? A Guide to Classifying Heating Equipment

- Why are leaching systems essential for reducing ash content in biomass materials? Enhance Fuel Quality and Boiler Life

- What is the physics of magnetron sputtering? Achieve Superior Thin Film Coating for Your Lab

- What precautions must be followed while working in a lab? Cultivate a Mindset of Proactive Awareness

- Which torch brazing has a high production rate, reduced costs, and uniform quality? Discover Automated Torch Brazing

- What is bio-oil carbon removal? A Permanent Solution for Capturing CO2 from Biomass Waste

- What happens in sample preparation? The Critical Step for Accurate Lab Analysis

- How do you test for filtration? Measure Upstream vs. Downstream for True Efficiency