The fundamental importance of a muffle furnace is its ability to provide an extremely hot, highly controlled, and contaminant-free environment. It achieves this by using an insulated outer chamber (the "muffle") to separate a sample from the furnace's heating elements and any combustion byproducts, ensuring that materials are heated cleanly and uniformly. This makes it an indispensable tool for material analysis, synthesis, and heat treatment across scientific and industrial fields.

The core value of a muffle furnace is not just its high heat, but the purity of that heat. By isolating a sample from contaminants, it guarantees the integrity of analytical tests and the quality of heat-treated materials.

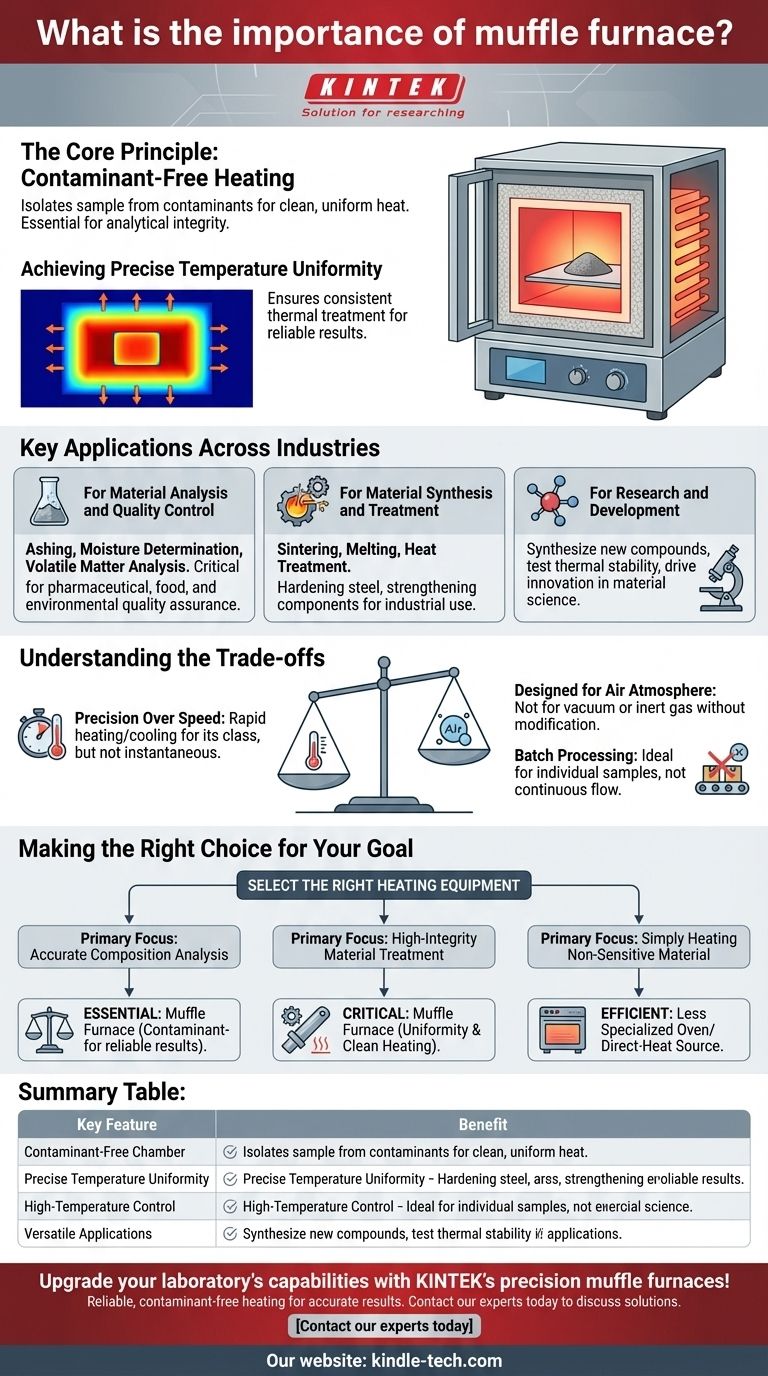

The Core Principle: Contaminant-Free Heating

A muffle furnace is far more than a simple high-temperature oven. Its design is engineered to deliver precise, clean, and uniform heat, which is critical for repeatable and accurate work.

What "Muffle" Means

The term "muffle" refers to the separating chamber inside the furnace. This chamber is made of high-heat-resistant material with excellent thermal conductivity.

It physically isolates the material being heated from the heating source. This ensures that byproducts of combustion or material from the heating elements themselves cannot contaminate the sample.

Achieving Precise Temperature Uniformity

Modern muffle furnaces are designed to distribute heat evenly throughout the interior chamber.

This temperature uniformity ensures that an entire sample or workpiece receives the same thermal treatment, which is essential for consistent results in both analysis and material processing.

Key Applications Across Industries

The unique capabilities of a muffle furnace make it a cornerstone piece of equipment in many sectors, from quality control labs to industrial production floors.

For Material Analysis and Quality Control

This is one of the most common uses. The furnace allows for the complete combustion of organic materials to determine the composition of the noncombustible remainder.

Key analytical processes include ashing (determining inorganic content), moisture determination, and analysis of volatile matter. This is critical in the pharmaceutical, food, environmental, and coal industries for quality assurance.

For Material Synthesis and Treatment

In industrial settings, muffle furnaces are used for a variety of thermal processes that alter a material's physical properties.

This includes sintering (fusing powders into a solid mass), melting, and the heat treatment of metal components like steel and copper to harden or strengthen them.

For Research and Development

In chemical and materials science labs, muffle furnaces are crucial for conducting high-temperature experiments.

Researchers use them to synthesize new compounds, test the thermal stability of materials, and perform foundational analyses that drive innovation.

Understanding the Trade-offs

While incredibly powerful, the design of a muffle furnace brings inherent trade-offs that are important to understand. Its specialized function is not a universal solution for all heating tasks.

Precision Over Speed

While a muffle furnace can heat and cool rapidly for its class, it is not an instantaneous process. For applications where a sample simply needs to be heated quickly and contamination is not a concern, a direct flame or a simpler convection oven may be faster.

Designed for Air Atmosphere

Standard muffle furnaces are designed to operate in a normal air atmosphere. They are not suitable for processes that require a vacuum or a specific inert gas environment (like argon or nitrogen) without significant, specialized modifications.

Batch Processing, Not Continuous Flow

The self-contained chamber design is ideal for processing individual samples or batches of components. It is not designed for continuous industrial processes where materials flow uninterrupted through a heating zone.

Making the Right Choice for Your Goal

Selecting the right heating equipment depends entirely on the requirements of your task. A muffle furnace is a specialized tool, and its value is unlocked when used for the right application.

- If your primary focus is accurate composition analysis: A muffle furnace is essential, as its contaminant-free environment is the only way to ensure reliable ashing or volatile matter results.

- If your primary focus is high-integrity material treatment: The temperature uniformity and clean heating of a muffle furnace are critical for achieving consistent material properties without introducing impurities.

- If your primary focus is simply heating a non-sensitive material: A less specialized oven or direct-heat source is likely a more efficient and cost-effective choice if sample purity and temperature precision are not top priorities.

Ultimately, a muffle furnace provides certainty and repeatability for any high-temperature process where purity matters.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Contaminant-Free Chamber | Isolates samples from heating elements and combustion byproducts |

| Precise Temperature Uniformity | Ensures consistent thermal treatment across entire samples |

| High-Temperature Control | Enables accurate material analysis and synthesis |

| Versatile Applications | Suitable for ashing, sintering, heat treatment, and R&D |

Upgrade your laboratory's capabilities with KINTEK's precision muffle furnaces!

As specialists in lab equipment and consumables, we understand that reliable, contaminant-free heating is essential for accurate material analysis and consistent results. Whether you're conducting quality control tests, developing new materials, or performing heat treatments, our muffle furnaces deliver the temperature uniformity and purity your work demands.

Ready to achieve superior thermal processing? Contact our experts today to discuss how KINTEK's muffle furnace solutions can enhance your laboratory's efficiency and accuracy.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How does thermal uniformity of a muffle furnace affect SA508 alloy? Master Carbide Precipitation and Fatigue Resistance

- How do you calibrate a muffle furnace? Achieve Precise Temperature Control for Your Lab

- How does heating in a muffle furnace after vacuum sealing study WTaVTiZrx alloys? Enhance High-Temp Material Stability

- What are the advantages and disadvantages to using a dry ashing technique? A Guide to High-Temperature Sample Prep

- What construction features contribute to the practicality and reliability of a muffle furnace? Key Design Elements for Lab Success

- What is a laboratory furnace called? A Guide to Muffle and Tube Furnaces

- How does the temperature control precision of a programmable furnace affect Nb-Ti alloy powders? Master Ductility

- What is the principle working and use of muffle furnace? Achieve Precise, Contamination-Free Heating