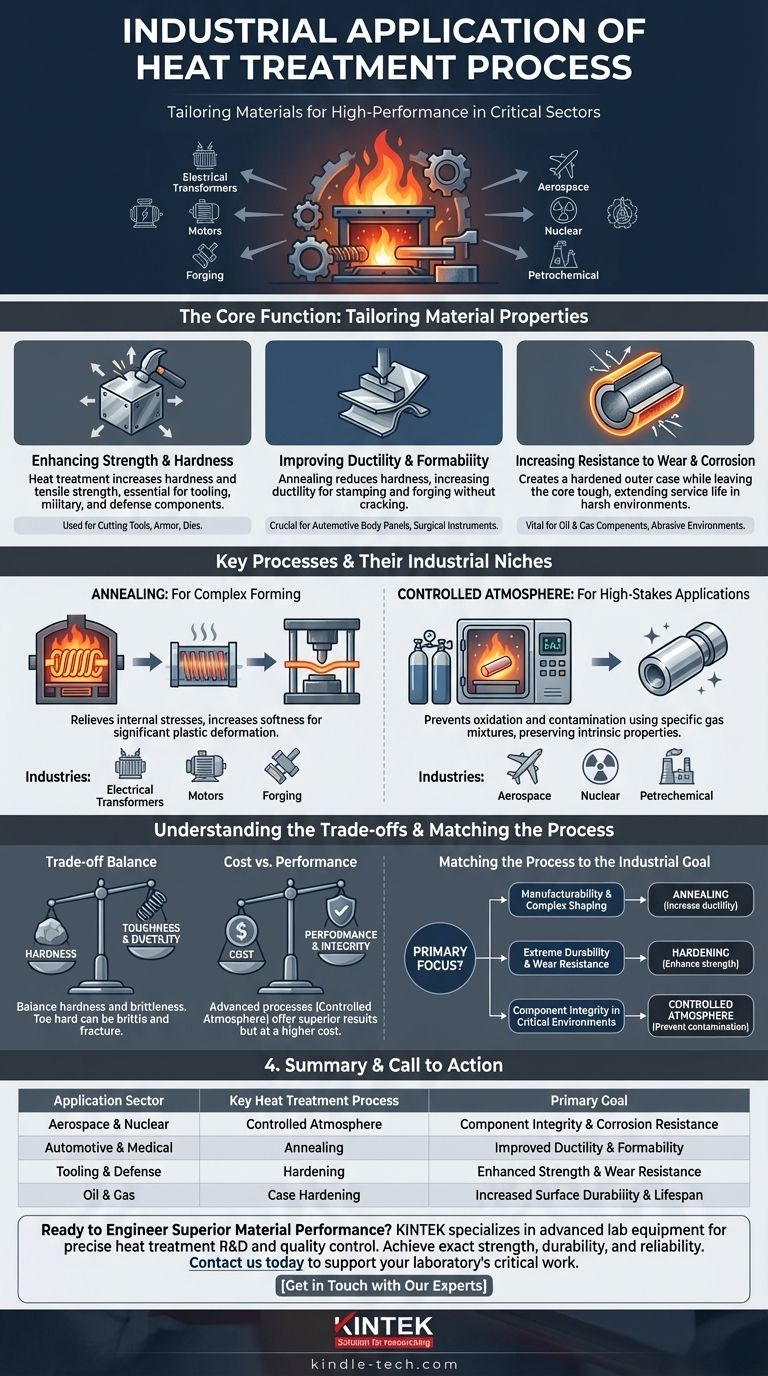

At its core, heat treatment is a foundational manufacturing process used to precisely engineer the properties of materials, especially metals. Its applications are vast, spanning critical sectors like aerospace, automotive, energy, military, healthcare, and electronics to ensure components have the exact strength, durability, and reliability required for their function.

Heat treatment is not a single action but a range of controlled heating and cooling techniques. Its industrial value lies in its ability to transform a standard material into a high-performance component tailored for a specific, demanding environment.

The Core Function: Tailoring Material Properties

The fundamental goal of any heat treatment process is to alter a material's physical and sometimes chemical properties. This allows engineers to start with a common alloy and customize it for a highly specific task.

Enhancing Strength and Hardness

For many applications, raw metal is too soft. Heat treatment can dramatically increase its hardness and tensile strength.

This is essential for the tooling industry, where cutting tools and dies must be harder than the material they work on. It is also critical for military and defense components that must withstand extreme forces.

Improving Ductility and Formability

Conversely, some manufacturing processes require the metal to be soft and easily shaped. Annealing is a key heat treatment process that reduces hardness and increases ductility.

This is crucial in industries like automotive and medical, where metal sheets must be stamped or forged into complex shapes—such as car body panels or surgical instruments—without cracking.

Increasing Resistance to Wear and Corrosion

In harsh environments, component failure often begins at the surface. Specific heat treatments can create a hardened outer case while leaving the inner core ductile and tough.

This is vital for industries like oil and gas, where components are exposed to abrasive materials and corrosive chemicals. It significantly extends the service life of critical parts.

Key Processes and Their Industrial Niches

Different industries rely on specific types of heat treatment to solve their unique challenges. The choice of process is dictated by the material alloy and the component's final application.

Annealing: For Complex Forming

Annealing is the process of choice when a metal part must undergo significant plastic deformation.

Industries that manufacture electrical transformers and motors rely on annealing to shape ferrous castings and other components. Likewise, the forging industry uses it to prepare metals for shaping under immense pressure.

Controlled Atmosphere Treatment: For High-Stakes Applications

For the most demanding applications, preventing any contamination during heat treatment is non-negotiable. Controlled atmosphere processes take place in a sealed chamber with a specific gas mixture.

This prevents oxidation and other reactions, preserving the alloy's intrinsic properties. It is a requirement in aerospace, nuclear, and petrochemical sectors, where components must perform flawlessly under extreme temperatures, pressures, and corrosive conditions.

Understanding the Trade-offs

Heat treatment is a science of balancing properties. Improving one characteristic often comes at the expense of another, which is a critical consideration for any application.

The Balance Between Hardness and Brittleness

A fundamental trade-off exists between hardness and toughness. As a metal becomes harder, it often becomes more brittle and susceptible to fracturing under sharp impact.

Engineers must select a heat treatment process that achieves the necessary hardness for wear resistance without making the component too brittle for its operational environment.

Cost vs. Performance

Advanced processes like controlled atmosphere treatment provide superior results but come at a significantly higher cost due to the specialized equipment and materials required.

For non-critical components, a simpler, less expensive heat treatment in open air may be sufficient. The choice is always an economic and engineering balancing act.

Risk of Distortion or Cracking

The rapid heating and cooling cycles inherent to heat treatment can introduce internal stresses. If not managed properly, this can cause a part to distort, warp, or even crack, rendering it useless.

This risk underscores the need for deep material science expertise and precise process control, which is why heat treatment is a highly specialized industrial field.

Matching the Process to the Industrial Goal

The selection of a heat treatment process is driven entirely by the performance requirements of the final component.

- If your primary focus is manufacturability and complex shaping: Annealing is the correct choice to increase ductility and prevent cracking during forming operations.

- If your primary focus is extreme durability and wear resistance: Hardening processes are essential for creating tools, gears, and bearings that can withstand intense friction and stress.

- If your primary focus is component integrity in critical, high-stress environments: Controlled atmosphere treatments are necessary to ensure alloys in aerospace or nuclear parts retain their designed properties without contamination.

Ultimately, heat treatment is the invisible but essential step that elevates standard materials to meet the extraordinary demands of modern industry.

Summary Table:

| Application Sector | Key Heat Treatment Process | Primary Goal |

|---|---|---|

| Aerospace & Nuclear | Controlled Atmosphere | Component Integrity & Corrosion Resistance |

| Automotive & Medical | Annealing | Improved Ductility & Formability |

| Tooling & Defense | Hardening | Enhanced Strength & Wear Resistance |

| Oil & Gas | Case Hardening | Increased Surface Durability & Lifespan |

Ready to Engineer Superior Material Performance?

Your components face demanding environments that require precise material properties. KINTEK specializes in providing the advanced lab equipment and consumables necessary for precise heat treatment R&D and quality control. Whether you are developing materials for aerospace, automotive, or medical devices, our solutions help you achieve the exact strength, durability, and reliability your applications demand.

Contact us today to discuss how we can support your laboratory's critical work in material science and ensure your heat treatment processes deliver optimal results.

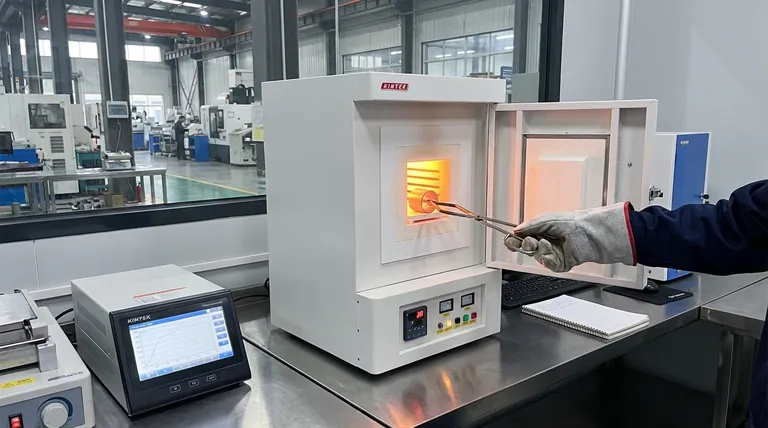

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the maximum temperature of a muffle furnace? Find the Right Heat for Your Application

- What is the most common form of heat treatment? Mastering Annealing, Hardening, and Tempering

- What is the melting temperature of ceramics? Understanding High-Temperature Material Performance

- What is the capacity of a muffle furnace? Find the Right Size for Your Lab Needs

- How does heat affect material strength? Understanding Thermal Degradation and Creep Failure