At its core, a muffle furnace is a specialized oven designed for high-temperature applications where the material being heated must be completely isolated from contaminants. It achieves this by heating the sample within a separate, insulated chamber, ensuring that fuel, combustion gases, and other residues never make direct contact with the workpiece. This makes it essential for processes requiring a pure, controlled atmosphere.

The fundamental purpose of a muffle furnace is not just to heat materials to extreme temperatures, but to do so in an entirely clean and uncontaminated environment. This separation between the heat source and the material is its defining characteristic.

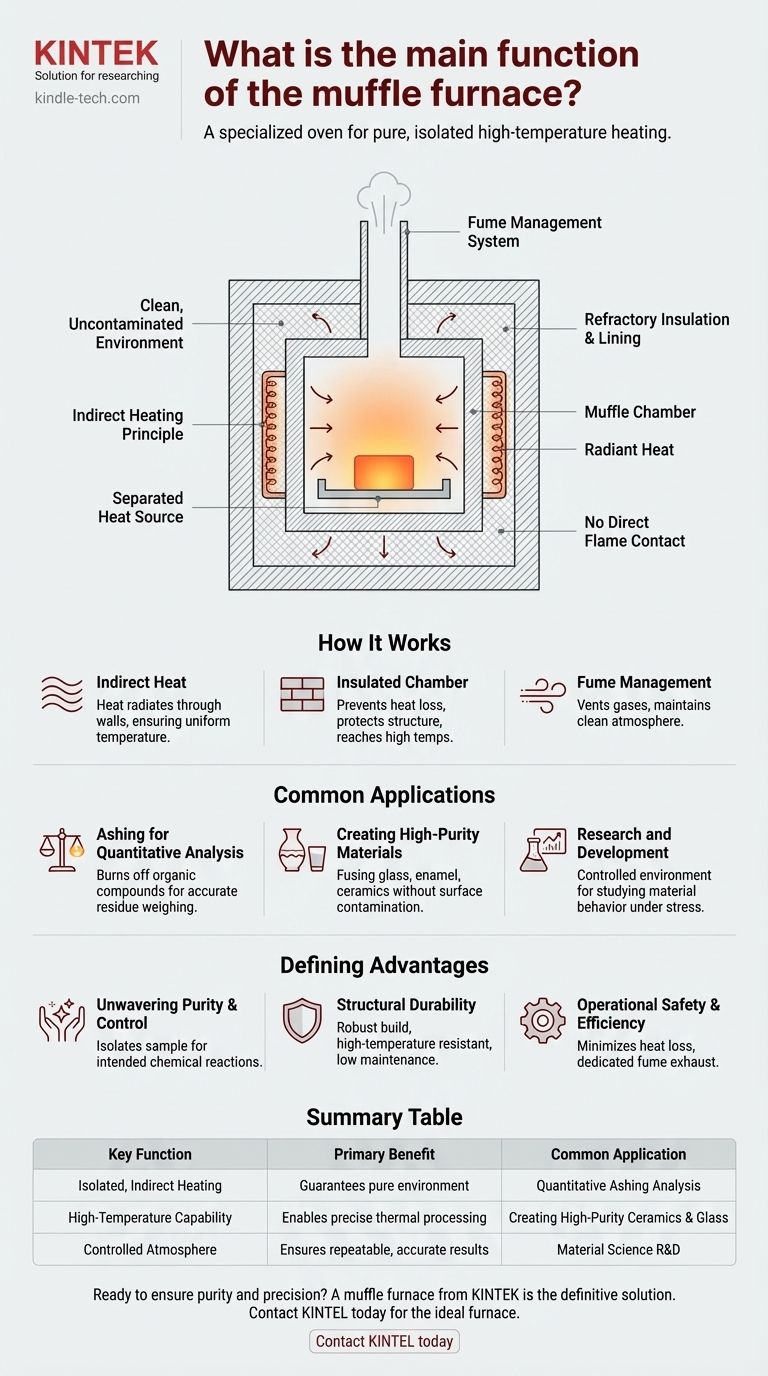

How a Muffle Furnace Provides a Clean Heating Environment

A muffle furnace's unique function comes from its specific design, which separates the heat source from the item being heated. This principle of indirect heating is what makes it an indispensable tool in many scientific and industrial fields.

The Principle of Indirect Heat

The name "muffle" refers to the inner chamber that encloses the workpiece. The heating elements or flame are located on the outside of this chamber.

Heat radiates through the walls of the muffle to raise the temperature inside, ensuring a uniform and stable thermal environment without any direct exposure to the heating source itself.

The Role of the Insulated Chamber

The entire furnace is lined with high-quality refractory bricks or insulation. This lining serves two critical purposes.

First, it prevents heat from escaping, allowing the furnace to reach and maintain very high temperatures efficiently. Second, it protects the furnace's structure and ensures a long service life.

Managing Fumes and Byproducts

Many processes, like burning off organic compounds, release gases from the material being tested.

A muffle furnace is equipped with an exhaust system specifically designed to vent these gases from the inner chamber. This maintains a clean internal atmosphere and ensures user safety, often eliminating the need for a separate fume hood.

Common Applications Driven by its Core Function

The ability to provide pure, high-temperature heat makes the muffle furnace essential for applications where material integrity is paramount.

Ashing for Quantitative Analysis

The primary use in a laboratory setting is ashing. This process involves burning a sample to completely remove all organic compounds.

By doing so, researchers can accurately determine the exact amount of inorganic, non-combustible material (ash) present in the original sample, a critical step in many forms of chemical analysis.

Creating High-Purity Materials

Industries rely on muffle furnaces for creating products where surface contamination would ruin the final result.

This includes fusing glass, creating delicate enamel coatings, fabricating advanced ceramics, and heat-treating metal parts without causing surface oxidation or discoloration.

Research and Development

A muffle furnace provides a highly controlled and repeatable environment. This allows scientists to study how different materials behave under extreme thermal stress without the results being skewed by impurities from the heating process itself.

The Defining Advantages of a Muffle Furnace

The design of a muffle furnace directly leads to several key operational benefits that make it a reliable tool for demanding applications.

Unwavering Purity and Control

The single most important advantage is the guarantee of a clean heating process. By isolating the sample, you ensure that the only chemical reactions occurring are the ones you intend.

Structural Durability and Longevity

These furnaces are typically built with a simple, robust structure. The use of high-temperature resistant, anti-corrosive materials and a step-type assembling structure prevents the hearth from collapsing and ensures a long, low-maintenance service life.

Operational Safety and Efficiency

The integral design of the door and door frame minimizes heat loss, improving energy efficiency. The dedicated exhaust system for fumes produced by the specimen enhances the safety of the operating environment.

Making the Right Choice for Your Goal

Understanding the core function of a muffle furnace—clean, isolated heat—clarifies when it is the right tool for the job.

- If your primary focus is quantitative analysis: A muffle furnace is essential for ashing, where you must burn off organic material to precisely weigh the inorganic residue without contamination.

- If your primary focus is material creation or treatment: Use a muffle furnace when the surface integrity and purity of your final product (like ceramics, glass, or enamel) are critical.

- If your primary focus is high-temperature research: This furnace provides the highly controlled and repeatable environment needed to study material properties without interference from combustion byproducts.

Ultimately, selecting a muffle furnace is a decision to prioritize a pure heating environment above all other factors.

Summary Table:

| Key Function | Primary Benefit | Common Application |

|---|---|---|

| Isolated, Indirect Heating | Guarantees a pure, uncontaminated environment | Quantitative Ashing Analysis |

| High-Temperature Capability | Enables precise thermal processing | Creating High-Purity Ceramics & Glass |

| Controlled Atmosphere | Ensures repeatable, accurate results | Material Science Research & Development |

Ready to ensure purity and precision in your high-temperature processes?

A muffle furnace from KINTEK is the definitive solution for laboratories that cannot compromise on material integrity. Whether your focus is quantitative ashing, creating high-purity materials, or critical R&D, our furnaces deliver the clean, isolated heating environment you require.

We specialize in supplying robust, reliable lab equipment tailored to your specific needs. Let our experts help you select the perfect furnace to enhance your lab's capabilities and safeguard your results.

Contact KINTEL today to discuss your application and find the ideal muffle furnace for your laboratory.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the role of a high-temperature box resistance furnace and protection bags in INCONEL 740H solution treatment?

- How does a high-temperature furnace maintain accuracy in biomass liquefaction? Explore Precise Thermal Stability

- What is the cooling rate of a muffle furnace? Understanding Its Slow, Passive Nature

- Can any metal be heat-treated? Unlock the Potential of Your Alloys

- Why is a high-temperature muffle furnace or tube furnace with precise temperature control necessary? | KINTEK

- How does a high-temperature box resistance furnace facilitate rare earth niobate synthesis? Key Steps to Success

- What is a muffle furnace used for burning? Mastering Controlled Thermal Processes

- Why is post-treatment in a muffle furnace necessary for Fenton catalyst synthesis? Optimize Your Nanoparticle Activity