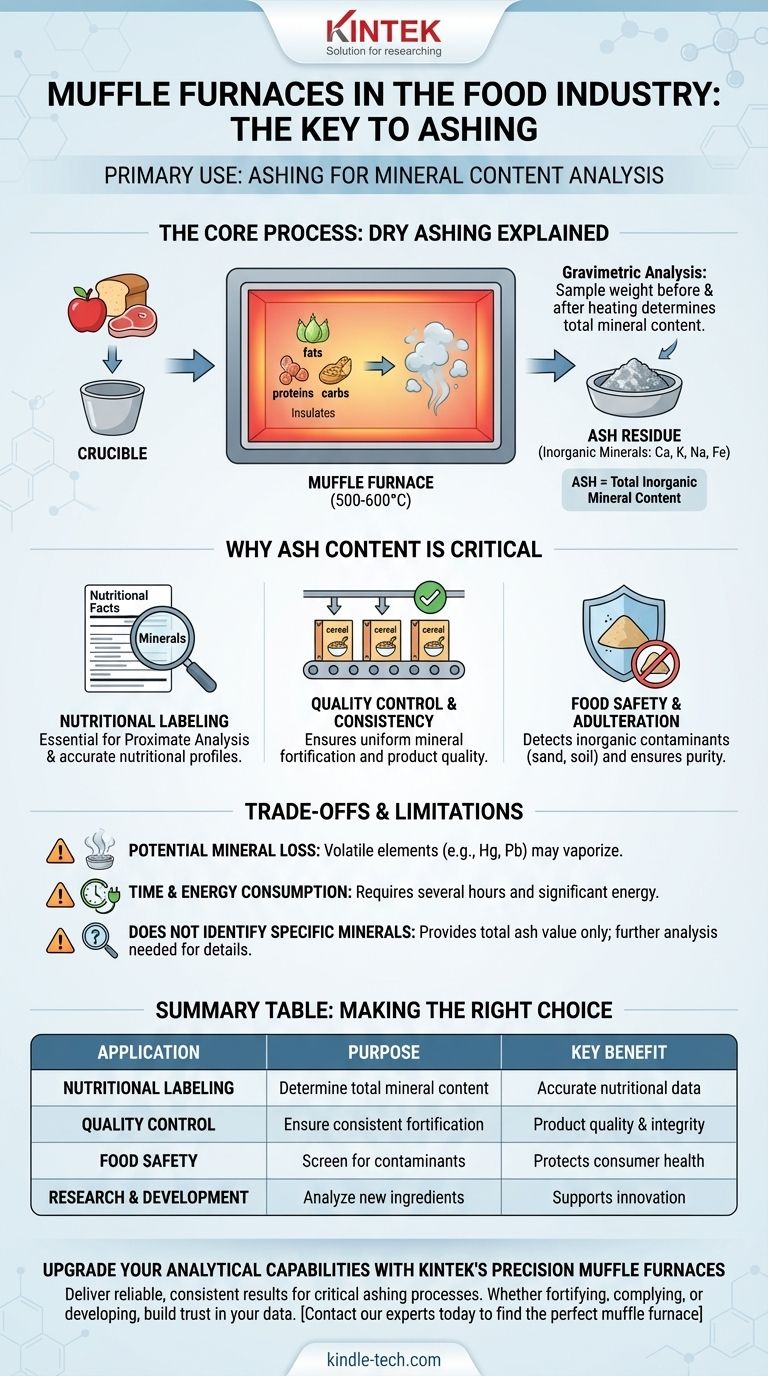

In the food industry, the primary use of a muffle furnace is for ashing. This is a critical laboratory process where a food sample is heated to extremely high temperatures (typically 500-600°C) to completely burn away all organic matter—such as fats, proteins, carbohydrates, and vitamins. What remains is a small amount of non-combustible residue, known as ash, which represents the total mineral content of the food.

The core challenge in food analysis is accurately separating and measuring its components. A muffle furnace solves this by providing the controlled, high-temperature environment needed to completely incinerate organic material, leaving behind only the inorganic mineral ash for precise measurement.

The Core Process: Dry Ashing Explained

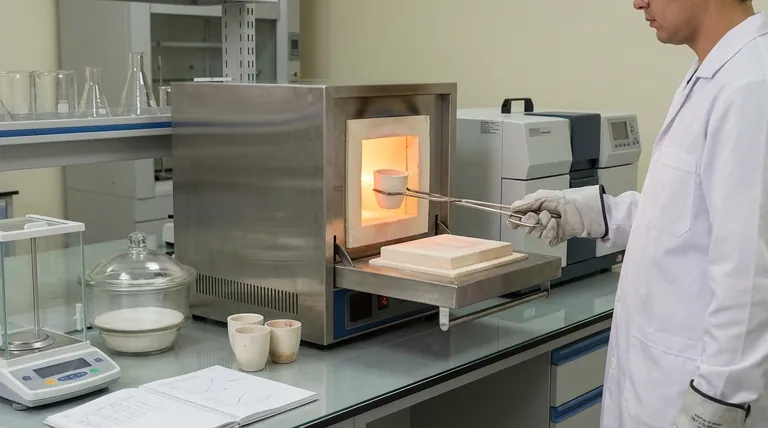

A muffle furnace is essentially a high-temperature oven with an insulated chamber that separates the sample from the direct heat source. This allows for uniform heating in a controlled atmosphere, which is essential for the analytical procedure known as dry ashing.

What is Food Ash?

Ash is the inorganic residue left after the water and organic matter have been completely removed by heating. This residue consists of the various minerals present in the food, such as calcium, potassium, sodium, and iron.

The total ash content is a fundamental measure of the overall mineral content in a food product.

How the Process Works

A pre-weighed food sample is placed in a heat-resistant crucible and put inside the muffle furnace. The furnace is then heated to a specific temperature and held there for several hours.

The high heat and presence of oxygen cause all organic compounds to oxidize and turn into gases (like carbon dioxide and water vapor), which dissipate. The only thing left in the crucible is the non-volatile mineral ash.

The Principle of Gravimetric Analysis

Ashing is a form of gravimetric analysis, which means analysis by weight. By carefully weighing the crucible with the sample before and after the ashing process, a technician can accurately determine the percentage of ash in the original food sample.

This simple but powerful technique provides a crucial data point about the food's composition.

Why Ash Content is Critical in Food Analysis

Measuring ash content is not just an academic exercise; it is a vital part of food production, quality control, and regulation. It serves as an important indicator of both nutritional value and quality.

Nutritional Labeling

The total mineral content is a key component of a food's nutritional profile. Ash analysis is one of the foundational steps in proximate analysis, the system used to determine the macronutrient and mineral composition for nutrition facts labels.

Quality Control and Consistency

Food manufacturers use ash measurements to ensure their products are consistent. For example, it can verify that mineral-fortified products like flour or breakfast cereals contain the correct amount of added minerals.

It also serves as a general index of quality. In products like flour, a higher ash content can indicate that more of the bran and germ were included, which affects the final product's texture and baking properties.

Food Safety and Adulteration

An unusually high ash content can be a red flag. It may indicate the presence of inorganic contaminants, such as sand, soil, or dirt, that were not properly washed away during processing. This makes it a useful screening tool for food purity.

Understanding the Trade-offs and Limitations

While powerful, the dry ashing method using a muffle furnace is not without its considerations. Understanding these limitations is key to interpreting the results correctly.

Potential for Mineral Loss

The extremely high temperatures can cause some volatile minerals to be partially or completely lost during the process. Elements like mercury, lead, chlorine, and zinc can vaporize, leading to an underestimation of their presence in the final analysis.

Time and Energy Consumption

The ashing process is not quick. It can take several hours to complete, from the initial heating ramp-up to the final cooling-down period. This process also consumes a significant amount of electrical energy due to the high temperatures involved.

Does Not Identify Specific Minerals

The total ash value tells you the amount of minerals but not the type. It provides a single number for the total inorganic content. Further analytical techniques, like spectroscopy, are needed to identify and quantify the individual minerals within the ash.

Making the Right Choice for Your Goal

The data from a muffle furnace is used to inform key decisions in different areas of the food industry.

- If your primary focus is nutritional labeling: Use the muffle furnace to determine the total ash content, a required value for calculating the complete nutritional profile of a food product.

- If your primary focus is quality assurance: Regularly test production samples to ensure mineral fortification levels are consistent and that products are free from inorganic contaminants like sand or soil.

- If your primary focus is research and development: Employ ashing as a foundational step to understand how new ingredients or processing methods affect the final mineral composition of a food product.

Ultimately, the muffle furnace is an indispensable tool that transforms a complex food sample into a simple, quantifiable measure of its essential mineral foundation.

Summary Table:

| Application | Purpose | Key Benefit |

|---|---|---|

| Nutritional Labeling | Determine total mineral content for nutrition facts. | Provides data for accurate nutritional profiles. |

| Quality Control | Ensure consistent mineral fortification and detect contaminants. | Maintains product quality and purity. |

| Food Safety | Screen for inorganic adulterants like sand or soil. | Protects consumer health and product integrity. |

| Research & Development | Analyze mineral composition of new ingredients or processes. | Supports innovation and product development. |

Upgrade your food laboratory's analytical capabilities with KINTEK's precision muffle furnaces.

Accurate ash analysis is fundamental to food quality, safety, and compliance. KINTEK specializes in high-performance lab equipment designed to deliver the reliable, consistent results your laboratory demands. Our muffle furnaces provide the precise temperature control and uniform heating necessary for critical processes like dry ashing.

Whether you are fortifying products, ensuring compliance, or developing new foods, our solutions help you build trust in your data and your brand.

Contact our experts today to find the perfect muffle furnace for your specific food testing needs and enhance your quality control protocols.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the theory of calcination? Master Precise Thermal Decomposition for Your Materials

- What is muffle furnace working principle and application? Achieve Contamination-Free High-Temperature Processing

- What is the main purpose of a furnace? A Guide to Heating, Comfort, and Material Transformation

- What is the importance of muffle furnace in laboratory? Achieve Precise, Contaminant-Free Heating

- What type of furnace is a muffle furnace? A Guide to High-Purity, Contamination-Free Heating