Laboratory equipment maintenance is the structured process of keeping scientific instruments in accurate and effective working order. It involves a combination of routine actions like cleaning and inspection, performance verification through calibration, and repair when a malfunction occurs.

Think of maintenance not as a background task, but as a critical control for your experiments. It is the essential activity that safeguards the integrity of your data, the safety of your lab personnel, and the longevity of your most valuable assets.

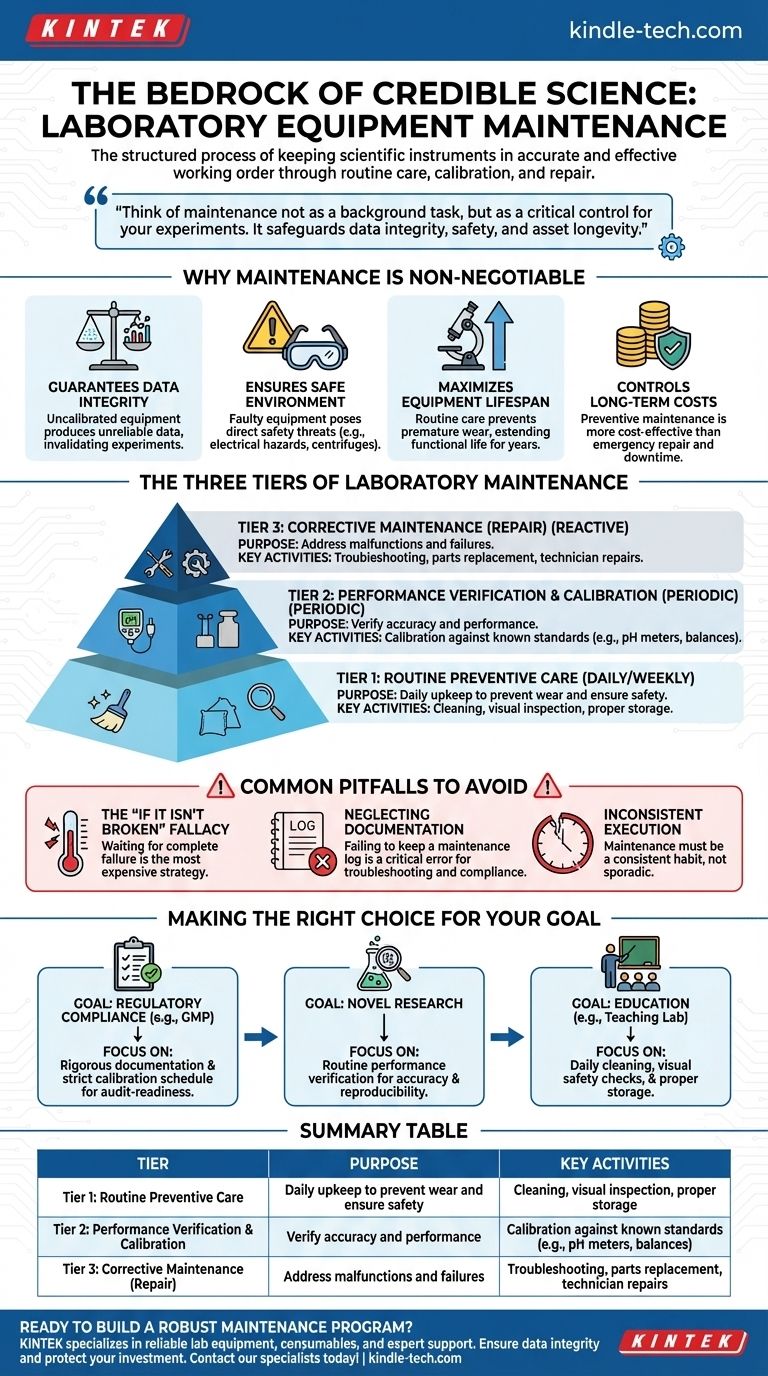

Why Maintenance Is Non-Negotiable

Effective maintenance is a core pillar of a functional laboratory, directly impacting scientific outcomes and operational stability. Neglecting it introduces unacceptable risks.

It Guarantees Data Integrity

Uncalibrated or poorly maintained equipment produces unreliable data. A balance that drifts or a pipette that dispenses the wrong volume can invalidate an entire experiment, wasting time and resources.

It Ensures a Safe Working Environment

Faulty equipment can be a significant hazard. Frayed electrical cords, failing pressure seals, or malfunctioning centrifuges pose direct threats to the safety of everyone in the lab.

It Maximizes Equipment Lifespan

Scientific instruments are a major capital investment. Routine care, like the simple act of covering a microscope to protect its lenses from dust, prevents premature wear and extends the functional life of the equipment for years.

It Controls Long-Term Costs

Preventive maintenance is always more cost-effective than emergency repair. The small, consistent investment in upkeep prevents catastrophic failures that lead to expensive downtime and service calls.

The Three Tiers of Laboratory Maintenance

A robust maintenance program is built on a tiered approach, moving from simple daily tasks to more complex, scheduled interventions.

Tier 1: Routine Preventive Care

This is the foundation of all maintenance and involves tasks performed on a daily or weekly basis by lab users.

These actions include wiping down surfaces, covering sensitive devices like analytical balances, performing visual inspections for damage, and ensuring the work area is clean.

Tier 2: Performance Verification & Calibration

This tier involves periodically testing equipment to ensure it is performing within specified tolerances.

For measuring instruments like pH meters, scales, and spectrophotometers, this means regular calibration against a known standard to guarantee accuracy.

Tier 3: Corrective Maintenance (Repair)

This is reactive maintenance performed when a piece of equipment malfunctions or fails.

It involves troubleshooting the problem, identifying the cause, and performing the necessary repairs, which may require a specialized service technician.

Common Pitfalls to Avoid

Simply knowing what maintenance is isn't enough. Success requires avoiding common but costly mistakes in execution.

The "If It Isn't Broken" Fallacy

Waiting for a complete failure is the most expensive maintenance strategy. Minor issues, if ignored, often cascade into major problems that require significant downtime and cost to resolve.

Neglecting Documentation

Failing to keep a maintenance log is a critical error. A logbook for each piece of major equipment provides a history for troubleshooting, demonstrates regulatory compliance, and holds users accountable.

Inconsistent Execution

Maintenance must be a consistent habit, not a sporadic effort. A formal schedule ensures that critical tasks are not forgotten and that every piece of equipment receives the attention it needs.

Making the Right Choice for Your Goal

Implementing a maintenance program begins with understanding your primary objective.

- If your primary focus is regulatory compliance (e.g., a clinical or GMP lab): Your priority must be rigorous documentation and a strict calibration schedule to ensure audit-readiness.

- If your primary focus is novel research: Emphasize routine performance verification to guarantee the accuracy and reproducibility of your experimental data.

- If your primary focus is education (e.g., a teaching lab): Concentrate on daily cleaning, visual safety checks, and proper storage to protect both students and assets.

Ultimately, a well-maintained laboratory is the bedrock of credible and impactful science.

Summary Table:

| Maintenance Tier | Purpose | Key Activities |

|---|---|---|

| Tier 1: Routine Preventive Care | Daily upkeep to prevent wear and ensure safety | Cleaning, visual inspection, proper storage |

| Tier 2: Performance Verification & Calibration | Verify accuracy and performance | Calibration against known standards (e.g., pH meters, balances) |

| Tier 3: Corrective Maintenance (Repair) | Address malfunctions and failures | Troubleshooting, parts replacement, technician repairs |

Ready to build a robust maintenance program for your lab?

KINTEK specializes in providing reliable lab equipment and consumables, along with expert support to keep your instruments in peak condition. Ensure your data's integrity and protect your investment—contact our specialists today for a consultation tailored to your laboratory's needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

People Also Ask

- What is the temperature limit on a muffle furnace? A Guide to Selecting the Right Model

- What hazard is involved when using a furnace? Protect Your Home from the Silent Killer

- What are the factors affecting the rate of melting process? Master Heat Transfer for Faster Results

- Does melting point ever change? Unlock the Secrets of Pressure and Purity

- What affects the melting point of a substance? Uncover the Key Factors & Forces