At its core, hydraulic press maintenance is a systematic process of inspection and fluid management. It primarily involves regularly checking for oil leaks, monitoring the hydraulic fluid level and condition, inspecting seals and hoses for wear, and ensuring the structural integrity of the frame and components.

The central goal of maintaining a hydraulic press is not just to keep it running, but to ensure operator safety and prevent catastrophic failures. A few minutes of regular inspection can prevent hours of downtime and costly repairs.

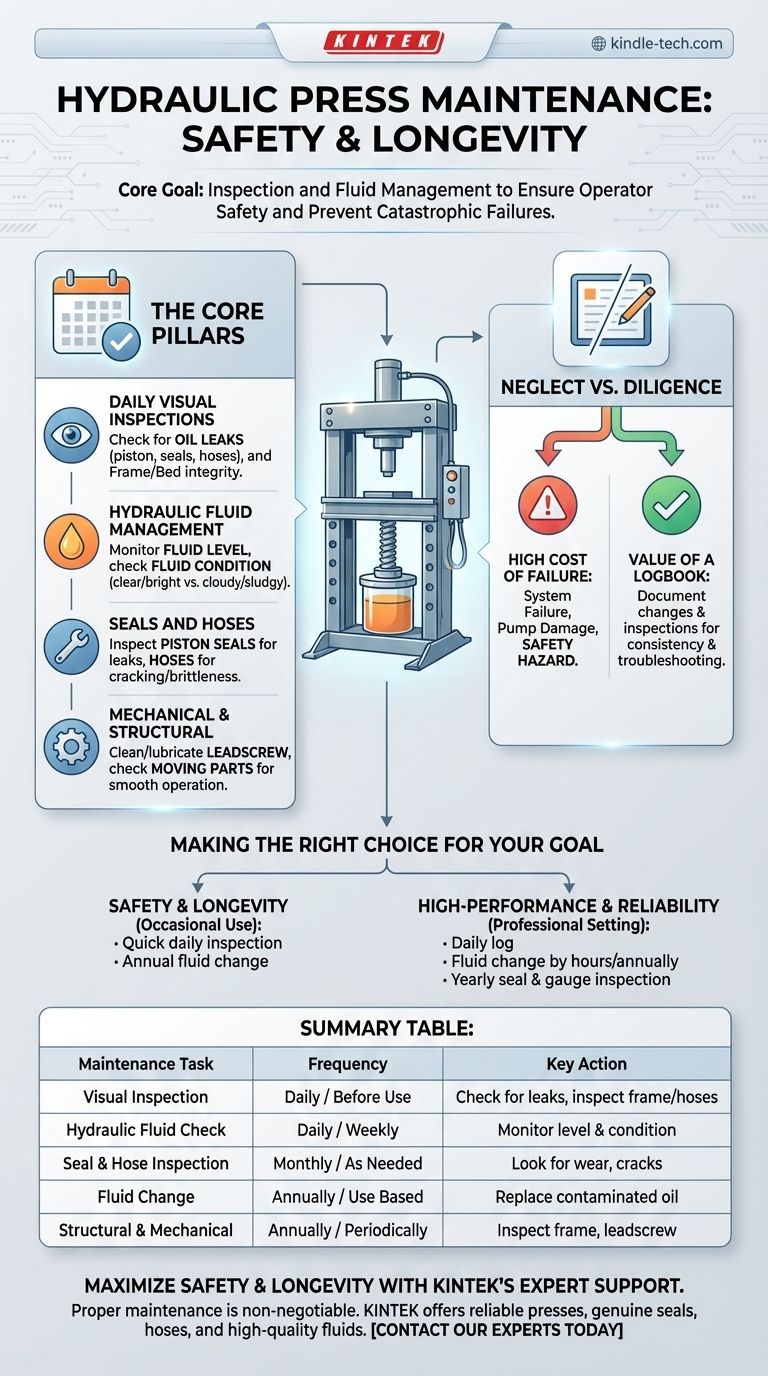

The Core Pillars of Hydraulic Press Maintenance

A reliable maintenance routine is built on a few key principles. These can be broken down into daily checks and less frequent, but equally critical, scheduled tasks.

Daily Visual Inspections

Before each use, a quick visual inspection is the most effective way to catch problems early.

Check for any signs of hydraulic oil leaks, particularly around the piston, seals, and hose connections. A small drip is a clear indicator of a failing seal or loose fitting that needs immediate attention.

Also, visually inspect the frame and bed for any signs of stress, cracks, or damage. Ensure all bolts and fasteners appear secure.

Hydraulic Fluid Management

The hydraulic fluid is the lifeblood of the press. It transfers force, lubricates components, and dissipates heat.

Always check the fluid level in the reservoir to ensure it is within the recommended operating range. Low fluid can cause the pump to draw in air, leading to poor performance and component damage.

Observe the fluid's condition. Clean hydraulic oil is typically clear and bright. If the oil appears cloudy, milky (indicating water contamination), or dark and sludgy, it's a sign that it needs to be changed.

Seals and Hoses

The seals and hoses are responsible for containing the immense pressure the system generates.

The piston seals are critical for maintaining pressure. Any leak from the main cylinder points to a worn or damaged seal that requires replacement.

Inspect all hoses for cracking, brittleness, or abrasions. A failing hose can rupture under pressure, creating a significant safety hazard.

Mechanical and Structural Integrity

Beyond the hydraulic system, the mechanical components require attention.

If your press has a leadscrew for positioning, ensure it is clean and properly lubricated to prevent binding and excessive wear.

Check that all moving parts, including the pump handle mechanism, operate smoothly without unusual noises or resistance.

Understanding the Trade-offs: Neglect vs. Diligence

It can be tempting to skip maintenance on a tool that seems to be working correctly, but this approach carries significant risks.

The High Cost of Failure

Neglecting a small oil leak from a worn seal can lead to a complete system failure. Running the press with low or contaminated oil can permanently damage the pump, a far more expensive repair than replacing fluid and seals.

Most importantly, a sudden failure of a hose or structural component under load is a serious safety hazard to the operator and anyone nearby.

The Value of a Logbook

The most effective way to ensure consistency is to keep a simple maintenance logbook.

Documenting the date of fluid changes, seal replacements, and any observations from inspections provides a clear history. This record is invaluable for troubleshooting future issues and establishing a predictable maintenance schedule.

Making the Right Choice for Your Goal

Your maintenance schedule should align with your primary use case for the press.

- If your primary focus is safety and longevity for occasional use: Perform a quick visual inspection for leaks before every use and commit to changing the hydraulic fluid annually.

- If your primary focus is high-performance and reliability in a professional setting: Implement a daily inspection log, change the fluid based on hours of use (or at least annually), and schedule a yearly inspection of all seals and gauges.

Consistent maintenance transforms your hydraulic press from a simple tool into a reliable and safe long-term asset.

Summary Table:

| Maintenance Task | Frequency | Key Action |

|---|---|---|

| Visual Inspection for Leaks & Damage | Daily / Before Use | Check for oil leaks, inspect frame and hoses |

| Hydraulic Fluid Check | Daily / Weekly | Monitor fluid level and condition for contamination |

| Seal & Hose Inspection | Monthly / As Needed | Look for wear, cracks, or brittleness |

| Fluid Change | Annually or Based on Use | Replace contaminated or degraded hydraulic oil |

| Structural & Mechanical Check | Annually / Periodically | Inspect frame, leadscrew, and moving parts |

Maximize the safety and longevity of your hydraulic press with KINTEK's expert support. Proper maintenance is non-negotiable for lab efficiency and operator protection. KINTEK specializes in lab equipment and consumables, offering reliable hydraulic presses, genuine replacement seals, hoses, and high-quality hydraulic fluids tailored to your laboratory's demands. Don't let neglect lead to costly downtime or safety risks—contact our experts today to ensure your press operates at peak performance!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- What are the disadvantages associated with the KBr technique? Avoid Common Errors in IR Spectroscopy

- Is compression molding a fast process? A Guide to Faster Time-to-Market for Low-Volume Production

- How much PSI does a hydraulic actuator usually operate at? A Guide to Industrial & High-Pressure Ranges

- How does pressure control of a laboratory hydraulic press affect W-Ti alloys? Optimize Grain Structure & Density

- What is a workshop press? Your Ultimate Guide to Controlled Force for Bending, Pressing, and Straightening

- How do you make a pellet sample? A 4-Step Guide to Perfect Pressed Pellets for Accurate Analysis

- What is the minimum sample required for XRD analysis? Optimize Your Material Analysis

- What is the role of a laboratory hydraulic press in LLZO pellet preparation? Enhance Ionic Conductivity via Cold Pressing