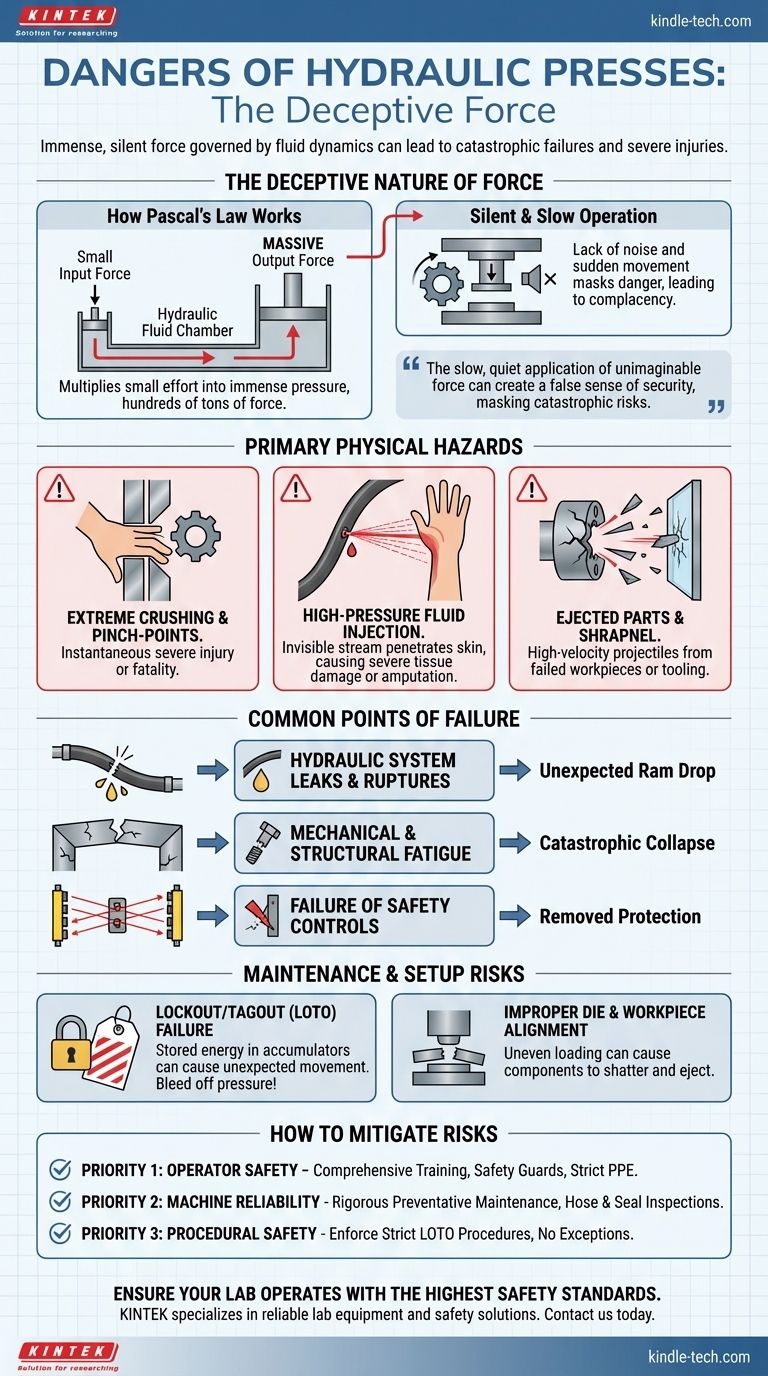

Hydraulic presses are dangerous because they generate and contain immense, silent, and often deceptive force. This power, governed by the principles of fluid dynamics, can lead to catastrophic failures and severe injuries, including crushing, high-pressure fluid injection, and injuries from ejected parts if not operated with extreme caution and respect.

The true danger of a hydraulic press lies not just in its obvious power, but in its nature. The slow, quiet application of unimaginable force can create a false sense of security, masking catastrophic risks from component failure, fluid injection, and human error.

The Deceptive Nature of Hydraulic Force

The core danger of a hydraulic press stems from how it generates force. It isn't fast or loud like a mechanical stamp press, which makes its power less intuitive and more insidious.

How Pascal's Law Creates Extreme Pressure

A hydraulic press uses Pascal's Law to multiply force. A small force applied to a small piston creates pressure in a sealed hydraulic fluid, and that pressure then acts on a much larger piston, generating an exponentially larger output force.

This multiplication factor is massive, allowing a small motor to generate hundreds or even thousands of tons of force.

The Dangers of Slow and Silent Operation

Unlike other heavy machinery, a hydraulic press ram often moves slowly and quietly. This lack of sudden movement or noise can lull an operator into a state of complacency, making it easy to misjudge the danger until it's too late.

Primary Physical Hazards

The application of this immense force creates several distinct and severe physical hazards that every operator and supervisor must understand.

Extreme Crushing and Pinch-Point Injuries

This is the most direct and obvious danger. The force exerted by the press is sufficient to crush any part of the human body instantly. Pinch points are created between the moving ram, the workpiece, and the stationary bed, leaving no margin for error.

High-Pressure Fluid Injection

A pinhole leak in a hydraulic hose can eject a nearly invisible stream of fluid at thousands of PSI. If this stream strikes an operator's skin, it can penetrate it and cause a high-pressure fluid injection injury.

This is a severe medical emergency that can lead to tissue death, gangrene, and amputation if not treated immediately by a specialist who understands the nature of the injury.

Ejected Parts and Shrapnel

When a workpiece or the tooling (dies) is improperly aligned or fails under load, the press can turn it into a high-velocity projectile. The sudden release of stored energy can send shrapnel across a workshop with lethal force.

Understanding the Trade-offs: Common Points of Failure

A press is a complex system, and its safety relies on the integrity of every component. Understanding these failure points is key to mitigating risk.

Hydraulic System Leaks and Ruptures

Hydraulic hoses and seals are under constant, extreme pressure. Over time, they can wear out, fatigue, and rupture catastrophically. A sudden failure releases high-pressure fluid and can cause the press ram to drop unexpectedly.

Mechanical and Structural Fatigue

The frame, bolts, and other structural components of the press endure immense cyclical loads. This can lead to metal fatigue and eventual structural failure, causing a complete collapse of the machine under load.

Failure of Safety Controls

Modern presses are equipped with safety features like light curtains, two-hand controls, and physical guarding. However, these systems can be bypassed by operators seeking shortcuts, or they can fail due to electrical or mechanical faults, removing the essential layers of protection.

The Overlooked Danger: Maintenance and Setup

Many of the most severe incidents occur not during normal operation, but when the machine is being prepared for a job or serviced.

The Critical Role of Lockout/Tagout (LOTO)

A press that is turned off can still contain enormous stored energy in its hydraulic accumulators. Failure to follow proper Lockout/Tagout (LOTO) procedures—which involves isolating the machine from its power source and bleeding off all stored pressure—can lead to unexpected movement during maintenance.

Risks from Improper Die and Workpiece Alignment

Incorrectly setting up the dies or failing to secure the workpiece can create uneven loading. This can cause the workpiece or tooling to shatter and be ejected from the press, a primary cause of projectile injuries.

How to Mitigate Hydraulic Press Risks

Understanding the "why" behind the dangers is the first step. Applying that knowledge through deliberate action is what ensures a safe working environment.

- If your primary focus is operator safety: Prioritize comprehensive training on specific machine hazards, mandate the use of all safety guards, and enforce strict personal protective equipment (PPE) protocols.

- If your primary focus is machine reliability: Implement a rigorous preventative maintenance schedule that specifically targets hydraulic hoses, seals, and structural weld points for inspection.

- If your primary focus is procedural safety: Enforce strict Lockout/Tagout (LOTO) procedures for all maintenance and setup activities, with absolutely no exceptions.

Ultimately, safety depends on a deep and unwavering respect for the immense stored energy the machine commands.

Summary Table:

| Hazard Type | Key Risk | Potential Consequence |

|---|---|---|

| Crushing | Immense force from ram movement | Severe or fatal injury |

| Fluid Injection | High-pressure hydraulic fluid leaks | Tissue damage, amputation |

| Ejection | Failed parts or tooling under load | Projectile injuries |

| System Failure | Hose rupture or structural fatigue | Catastrophic machine failure |

Ensure your lab operates with the highest safety standards. KINTEK specializes in reliable lab equipment and consumables, providing robust hydraulic presses and safety solutions tailored to laboratory needs. Don't compromise on safety—contact us today to learn how our products can protect your team and enhance your operational security.

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is a sintering process? A Guide to Fusing Powders into High-Performance Parts

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- How is the pressure and temperature process used to make a synthetic diamond? Replicate Earth's Diamond Formation in a Lab