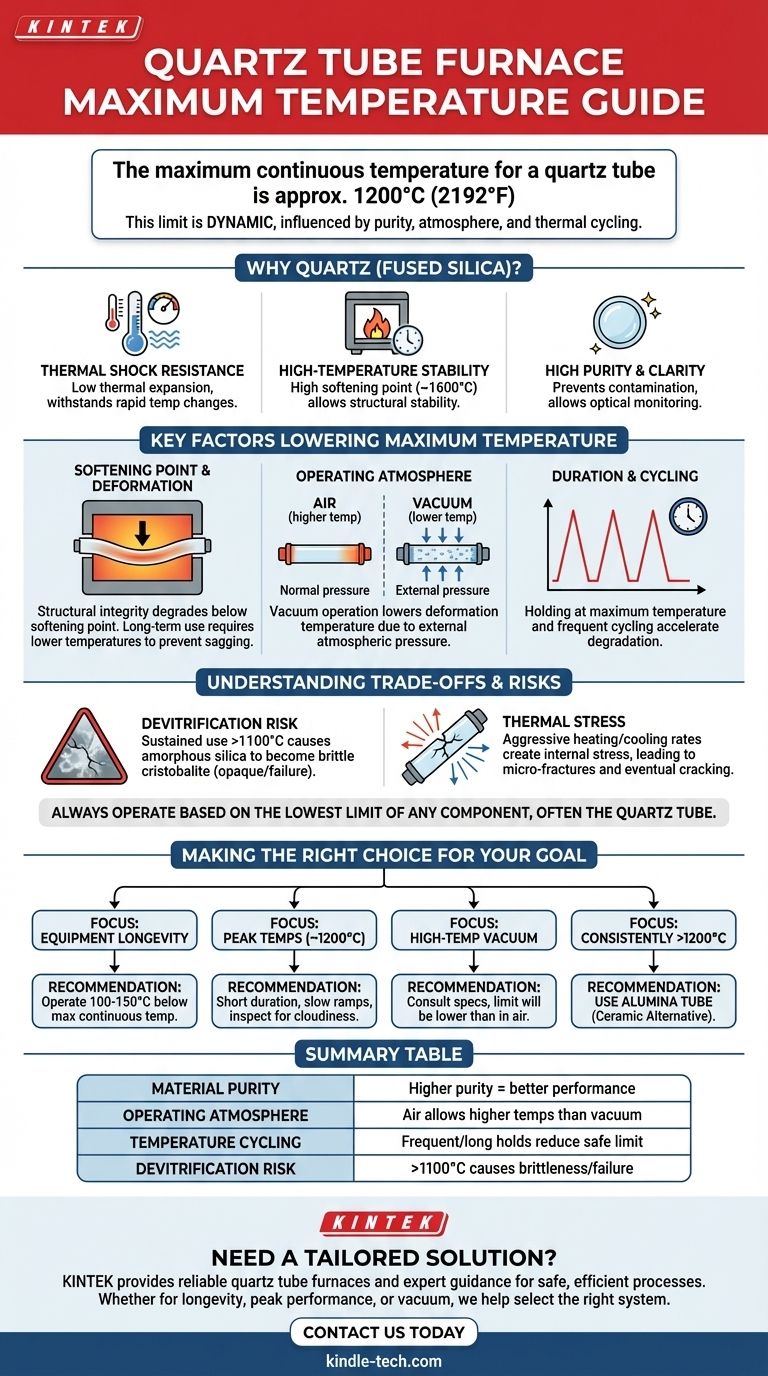

The maximum temperature for a quartz tube furnace is dictated by the physical limits of quartz itself, which is typically rated for continuous use up to approximately 1200°C (2192°F). However, this figure is not an absolute guarantee. The true operational ceiling is significantly influenced by factors such as the purity of the quartz, the atmospheric conditions (air vs. vacuum), and the rate of temperature change.

The number printed in a manual is only a starting point. The true maximum temperature of your quartz tube is a dynamic limit, determined by a trade-off between your processing goals, the operational environment, and the acceptable lifespan of the tube.

Why Quartz is a Standard for High-Temperature Work

Understanding why quartz is used reveals its operational limits. The material valued in laboratory and industrial settings isn't crystalline quartz but rather high-purity fused silica, which is commonly referred to as "quartz glass."

Exceptional Thermal Shock Resistance

Fused silica has an extremely low coefficient of thermal expansion. This means it expands and contracts very little when heated or cooled, allowing it to withstand rapid temperature changes that would shatter ordinary glass.

High-Temperature Stability

It possesses a very high softening point (around 1600°C), which allows it to remain rigid and structurally stable at the temperatures required for many chemical and physical processes.

High Purity and Optical Clarity

Fused silica can be produced with exceptionally high purity, which is critical for preventing contamination in sensitive processes like semiconductor manufacturing. Its transparency also allows for visual monitoring and certain light-based reactions.

Key Factors That Lower the Maximum Temperature

The theoretical limits of a material rarely match its practical, day-to-day performance. Several factors work together to reduce the safe operating temperature of a quartz tube.

The Softening Point

While quartz softens around 1600°C, its structural integrity begins to degrade at much lower temperatures. Long-term use requires staying well below this point to prevent the tube from sagging or deforming under its own weight.

The Operating Atmosphere

The environment inside the tube is critical. A furnace operating in air can typically sustain higher temperatures than one under vacuum. Under vacuum, the tube is subjected to significant external atmospheric pressure (14.7 psi at sea level), which can lower its deformation temperature.

Duration and Cycling

The rated temperature of a furnace system is often a peak figure, not a continuous operating point. Holding a quartz tube at its maximum temperature for extended periods accelerates degradation and drastically shortens its lifespan.

Understanding the Trade-offs and Risks

Operating a quartz tube furnace is a balancing act. Pushing for higher temperatures introduces clear risks that must be managed.

The Risk of Devitrification

This is the primary failure mode for quartz tubes. At sustained temperatures above 1100°C, the amorphous glass structure of fused silica can slowly revert to its crystalline state (cristobalite). This process, devitrification, makes the quartz opaque and extremely brittle, leading to catastrophic failure.

Thermal Stress from Rapid Change

Even with excellent thermal shock resistance, aggressive heating or cooling rates create internal stress. This stress can lower the effective maximum temperature and introduce micro-fractures that grow over time, eventually causing the tube to crack.

The Furnace vs. The Tube

It is crucial to remember that a furnace heating element may be rated for a much higher temperature (e.g., 1500°C or more) than the quartz process tube can handle. You must always operate based on the lowest temperature limit of any component in your system, which is very often the quartz tube itself.

Making the Right Choice for Your Goal

To ensure safety and achieve repeatable results, match your operating parameters to your specific objective.

- If your primary focus is equipment longevity: Operate your quartz tube at least 100-150°C below its stated maximum continuous-use temperature.

- If your primary focus is reaching peak temperatures near 1200°C: Use this temperature only for short durations, implement slow heating and cooling ramps, and inspect the tube for cloudiness (devitrification) after each cycle.

- If your primary focus is high-temperature vacuum processing: Consult the manufacturer's specifications for vacuum use, as the effective temperature limit will likely be lower than in an air atmosphere.

- If your process requires temperatures consistently above 1200°C: Quartz is the wrong material. You must use a ceramic alternative, such as an alumina tube.

Respecting the material science of quartz is fundamental to safe and successful high-temperature work.

Summary Table:

| Factor | Impact on Maximum Temperature |

|---|---|

| Material Purity | Higher purity fused silica offers better high-temperature performance. |

| Operating Atmosphere | Air allows higher temps than vacuum due to pressure differences. |

| Temperature Cycling | Frequent heating/cooling or long holds reduce the safe operating limit. |

| Devitrification Risk | Sustained use above ~1100°C causes brittleness and failure. |

Need a high-temperature furnace solution tailored for your specific application?

KINTEK specializes in lab equipment and consumables, providing reliable quartz tube furnaces and expert guidance to ensure your processes are both safe and efficient. Whether your priority is longevity, peak temperature performance, or vacuum processing, we can help you select the right system.

Contact us today to discuss your requirements and let our experts provide a solution that maximizes your lab's productivity. Get in touch via our contact form!

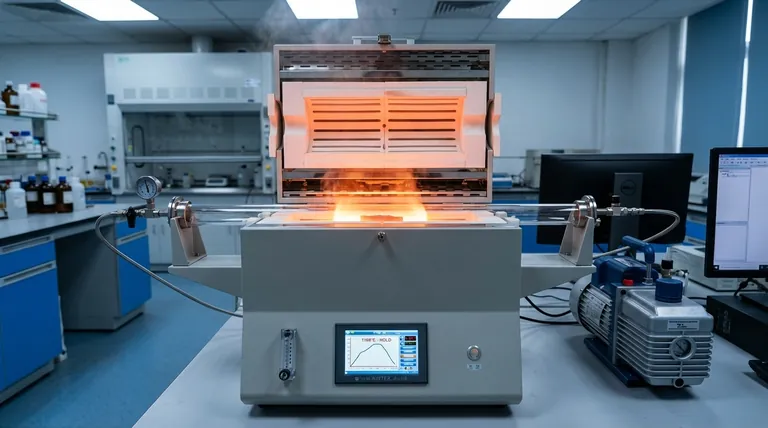

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vertical Laboratory Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance