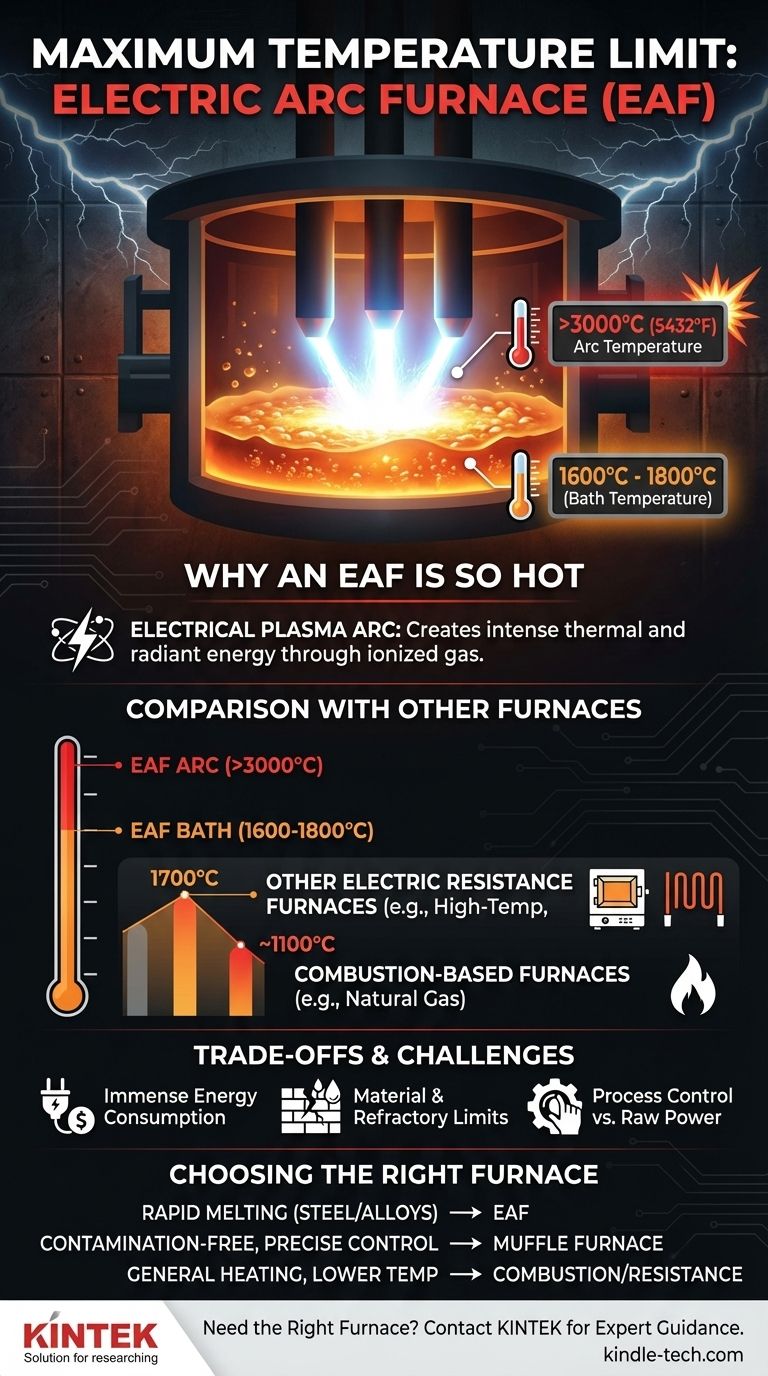

At its core, the temperature in the arc area of an Electric Arc Furnace (EAF) can exceed 3000°C (5432°F). This extreme temperature is highly localized to the electric arc itself, which is the source of the furnace's immense melting power.

The critical distinction to understand is that the Electric Arc Furnace's extreme temperature capability comes from its heating method—creating an electrical plasma arc—which is fundamentally different from and significantly hotter than the chemical combustion used in most other industrial furnaces.

Why an Electric Arc Creates Extreme Heat

The unique capability of the EAF stems directly from the physics of its operation. It does not burn fuel; it uses electrical energy to create conditions hot enough to melt steel and other alloys rapidly.

The Principle of the Electric Arc

An EAF works by passing an enormous electrical current through large graphite electrodes. When the electrodes are brought close to the metal scrap inside the furnace, the high voltage causes electricity to jump the gap.

This discharge of electricity ionizes the gas in the gap, creating a sustained arc of plasma. This plasma is the source of the intense thermal and radiant energy, with localized temperatures soaring above 3000°C.

Arc vs. Bath Temperature

It is crucial to differentiate between the temperature of the arc and the temperature of the molten metal, known as the bath.

While the arc itself is incredibly hot, the overall furnace operation targets a much lower, controlled temperature for the molten bath, typically around 1600°C to 1800°C for steelmaking. The furnace's job is to transfer the arc's energy to the metal as efficiently as possible.

How EAFs Compare to Other Furnace Technologies

The temperature of an EAF puts it in a class of its own. Comparing it to other common furnaces highlights the significant difference in heating technology.

Combustion-Based Furnaces

Furnaces that burn fuel, such as natural gas furnaces, are limited by the chemical energy released during combustion. These typically reach maximum temperatures around 1093°C (2000°F). This is effective for many processes but insufficient for efficiently melting large quantities of steel.

Other Electric Resistance Furnaces

Many electric furnaces do not use an arc. Instead, they use electric resistance heating, where electricity flows through a heating element.

Furnaces like high-temperature furnaces (1700°C), bottom-loading furnaces (1600°C), and many muffle furnaces (1100°C to 1700°C) use this method. They offer excellent temperature control but cannot generate the raw, concentrated power of an electric arc.

The Muffle Furnace Distinction

A muffle furnace is defined by its design: a chamber (the "muffle") isolates the material being heated from the heat source to prevent contamination.

Their maximum temperature varies widely based on the heat source. A muffle furnace heated by a gas burner might reach 1200°C, while an electrically heated one can reach up to 1700°C.

Understanding the Trade-offs

The extreme temperature of an EAF is not without its challenges and limitations. The engineering required to contain and control this energy is significant.

Immense Energy Consumption

Generating a stable, high-temperature arc requires a massive amount of electricity. Energy consumption is one of the highest operational costs for any facility running an EAF.

Material and Refractory Limits

No furnace lining can withstand a direct, sustained blast of 3000°C heat. The furnace's refractory lining is protected by a layer of slag and sophisticated, water-cooled panels that prevent the steel shell from melting. The design is focused on directing the arc's energy into the metal, not the furnace walls.

Process Control vs. Raw Power

The goal is not simply to achieve the highest possible temperature, but to control the application of that energy. Skilled operators must manage the arc to ensure an efficient and safe melting process, balancing power input with the condition of the metal and the furnace lining.

Matching the Furnace to the Task

Choosing the right furnace technology is entirely dependent on the material and the process goal.

- If your primary focus is rapidly melting scrap steel or high-melting-point alloys: The Electric Arc Furnace is the unmatched choice for its sheer power and speed.

- If your primary focus is heat treatment, sintering, or lab analysis without contamination: A Muffle Furnace provides the necessary isolation and precise temperature control.

- If your primary focus is general heating or lower-temperature processing: A simpler combustion or electric resistance furnace offers a more cost-effective and controllable solution.

Ultimately, the right technology is the one that delivers the required heat under the right conditions for your specific application.

Summary Table:

| Furnace Type | Maximum Temperature (Typical) | Primary Heating Method | Key Application |

|---|---|---|---|

| Electric Arc Furnace (EAF) | > 3000°C (Arc); 1600-1800°C (Bath) | Electric Arc (Plasma) | Rapid melting of steel/scrap |

| Muffle Furnace (Electric) | Up to 1700°C | Electric Resistance | Contamination-free heat treatment, lab analysis |

| Combustion Furnace (e.g., Gas) | ~1100°C | Fuel Combustion | General lower-temperature processing |

Need the Right Furnace for Your Lab or Production Process?

Choosing between extreme heat, precise control, and contamination-free environments is critical. KINTEK specializes in lab equipment and consumables, serving all your laboratory needs.

We provide expert guidance to help you select the perfect furnace technology—whether you require the raw power of an arc furnace or the precision of a muffle furnace—ensuring optimal performance for your specific materials and goals.

Contact us today to discuss your application and let our specialists match you with the ideal solution.

Get in touch with our experts now!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process