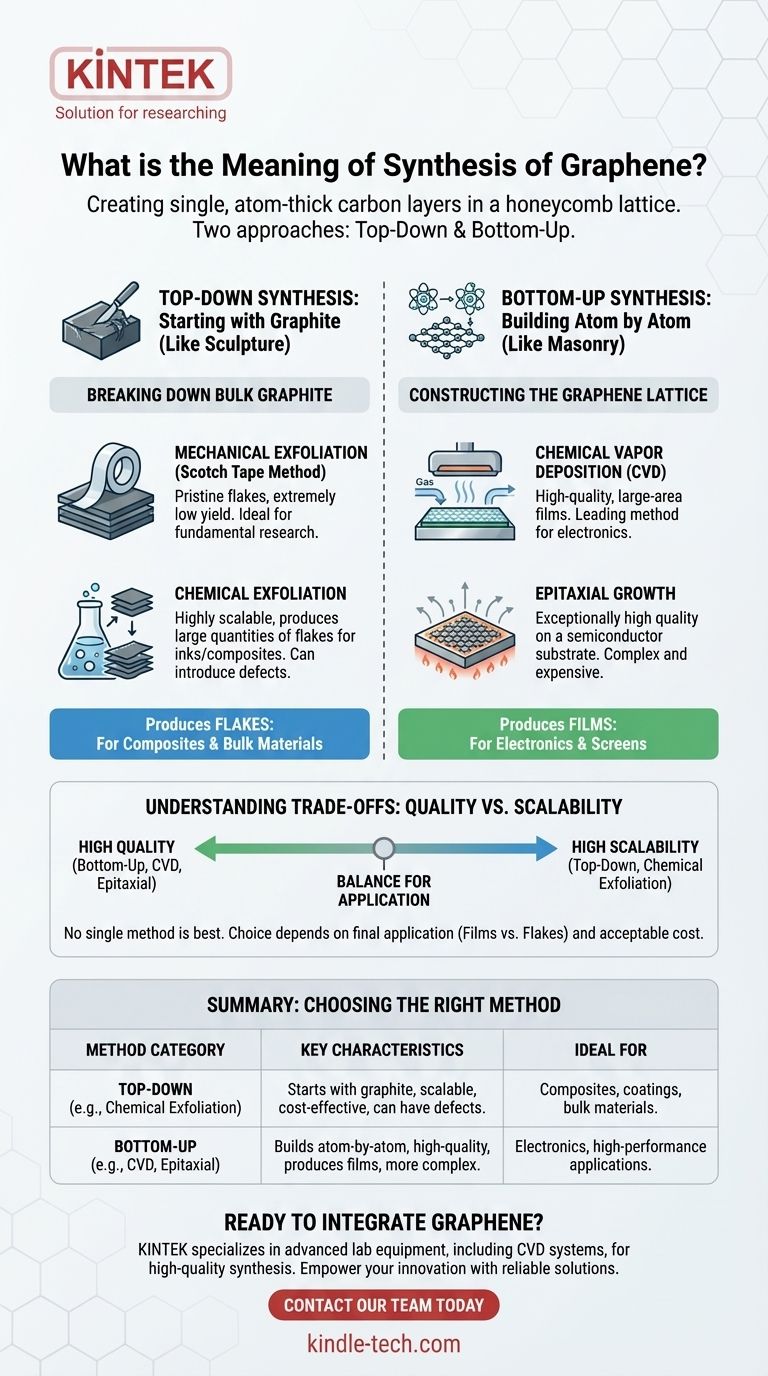

In essence, the synthesis of graphene is the process of creating or isolating single, atom-thick layers of carbon arranged in a two-dimensional honeycomb lattice. All methods for achieving this fall into one of two fundamental categories: either breaking down bulk graphite into single layers (top-down) or building the graphene sheet up from individual carbon atoms (bottom-up).

The core challenge in graphene synthesis is not simply making it, but producing it with the right quality, at the right scale, and for the right cost. The choice between a "top-down" or "bottom-up" approach fundamentally dictates the properties of the final material and its suitability for any given application.

The Two Philosophies of Graphene Synthesis

Nearly every method to create graphene can be understood through two opposing strategies. One approach is like sculpture—starting with a large block and carving away until you have your desired form. The other is like masonry—building a structure brick by brick.

Top-Down Synthesis: Starting with Graphite

Top-down methods begin with graphite, which is essentially a stack of countless graphene layers, and find ways to separate them. This is conceptually like separating the individual pages of a very thick book.

Mechanical Exfoliation (The "Scotch Tape" Method)

This is the original, Nobel Prize-winning technique. It involves using adhesive tape to peel layers from a piece of graphite repeatedly until a single layer is isolated.

While it can produce pristine, nearly perfect graphene flakes ideal for fundamental research, the process has extremely low yield and is not scalable for industrial or commercial use.

Chemical Exfoliation

This approach uses chemical processes to overcome the forces holding the graphite layers together. A common method involves oxidizing the graphite to form graphite oxide, which separates more easily in water, and then using a chemical reducer to convert the separated layers back into graphene.

This method is highly scalable and can produce large quantities of graphene flakes suspended in a liquid, making it suitable for inks, coatings, and composites. However, the chemical process often introduces defects into the graphene's structure, which can impact its electrical properties.

Bottom-Up Synthesis: Building Graphene Atom by Atom

Bottom-up methods construct the graphene lattice from the ground up, typically by providing a source of carbon atoms onto a substrate where they can self-assemble. This is like laying individual tiles to create a perfect, seamless floor.

Chemical Vapor Deposition (CVD)

CVD is the leading method for producing large-area, high-quality graphene films. In this process, a carbon-containing gas (like methane) is passed over a metallic catalyst substrate, such as copper foil, inside a high-temperature furnace.

The heat breaks down the gas, and carbon atoms deposit onto the metal surface, arranging themselves into a continuous graphene sheet. This film can then be transferred to other substrates like silicon wafers for use in electronics.

Epitaxial Growth

This method involves heating a substrate like a silicon carbide (SiC) wafer to extremely high temperatures. The heat causes silicon atoms to evaporate from the surface, leaving behind carbon atoms that rearrange themselves into a graphene layer directly on the wafer.

This process produces exceptionally high-quality graphene that is already on a semiconductor-compatible substrate, but it is a more complex and expensive method than CVD.

Understanding the Trade-offs: Quality vs. Scalability

No single synthesis method is "best" in all situations. The choice always involves a trade-off between the quality of the graphene, the quantity that can be produced, and the overall cost.

The Form Factor: Films vs. Flakes

A critical distinction is the form of the final product. Bottom-up methods like CVD create continuous films, which are essential for applications like transparent conductive screens and electronic circuits.

Top-down methods typically produce discrete flakes or platelets, which are then mixed into other materials (like polymers or concrete) to create composites with enhanced properties.

The Quality and Cost Spectrum

Bottom-up methods (CVD, epitaxial growth) generally yield higher-quality, defect-free graphene but are more complex and expensive. They are the preferred choice when pristine electronic properties are critical.

Top-down methods (chemical exfoliation) are far more cost-effective for producing graphene in bulk, but the resulting material has more structural defects. This is acceptable and often desired for mechanical reinforcement or conductivity in composites.

Making the Right Choice for Your Goal

Selecting a synthesis method depends entirely on your end-use application and performance requirements.

- If your primary focus is high-performance electronics: Your best path is a bottom-up method like CVD to create large, defect-free films.

- If your primary focus is bulk materials and composites: Top-down chemical exfoliation is the most cost-effective way to produce large quantities of graphene flakes.

- If your primary focus is fundamental research: Mechanical exfoliation remains a valuable tool for obtaining small, pristine samples for precise laboratory measurements.

Understanding these synthesis pathways empowers you to select the precise form of graphene that meets your specific technical and economic requirements.

Summary Table:

| Method Category | Key Methods | Key Characteristics | Ideal For |

|---|---|---|---|

| Top-Down | Mechanical Exfoliation, Chemical Exfoliation | Starts with graphite, produces flakes, scalable, cost-effective, can have defects. | Composites, coatings, bulk materials. |

| Bottom-Up | Chemical Vapor Deposition (CVD), Epitaxial Growth | Builds atom-by-atom, produces films, high-quality, more complex/expensive. | Electronics, high-performance applications. |

Ready to integrate graphene into your research or product development? The right synthesis method is critical to your success. At KINTEK, we specialize in providing the advanced lab equipment, including CVD systems, essential for high-quality graphene synthesis. Our experts can help you select the perfect solution for your specific application, whether you're focused on electronics, composites, or fundamental research. Contact our team today to discuss your project requirements and discover how KINTEK can empower your innovation with reliable laboratory solutions.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit