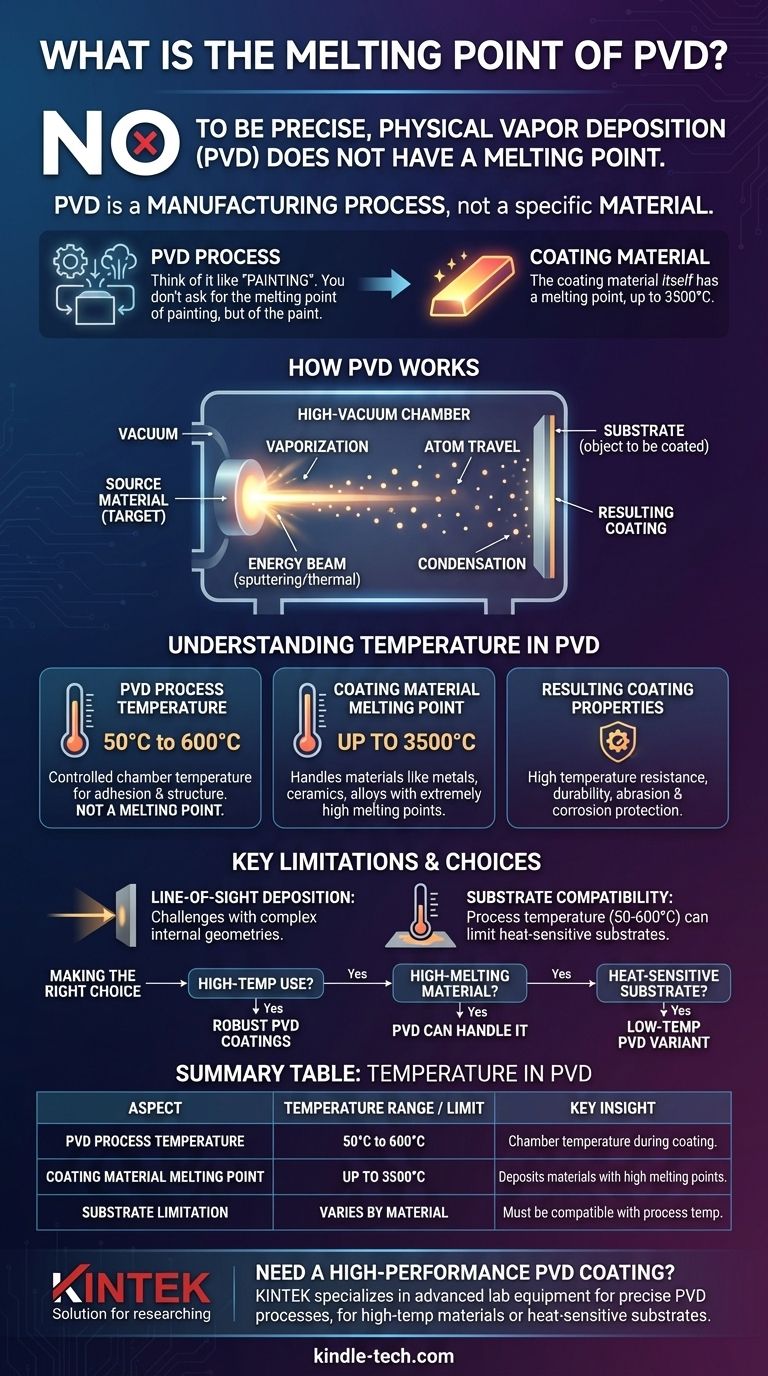

To be precise, Physical Vapor Deposition (PVD) does not have a melting point. This is because PVD is a manufacturing process, not a specific material. The PVD process is a vacuum deposition technique used to apply thin-film coatings of various materials, and it is the coating material itself that has a melting point, which can be as high as 3500°C.

The core misunderstanding is asking for the melting point of a process. The relevant questions are about the temperature limits of the PVD process chamber and the thermal properties of the resulting PVD coating.

What PVD Is (And Why It Has No Melting Point)

A Process, Not a Substance

Physical Vapor Deposition is a general term for a family of coating techniques. Think of it like "painting" or "welding"—you wouldn't ask for the melting point of painting, but you would ask about the properties of the paint.

PVD methods include sputtering, thermal evaporation, and electron beam deposition. All of them operate under the same principle.

How PVD Works

In a high-vacuum chamber, a solid source material (the "target") is vaporized. These vaporized atoms then travel through the vacuum and condense onto a substrate, forming a very thin, highly durable coating.

Understanding Temperature in the PVD Context

The Process Temperature

The PVD process itself takes place within a chamber at a controlled temperature, typically ranging from 50°C to 600°C.

This temperature is chosen to optimize the coating's adhesion and structure; it is not a melting point.

The Coating Material's Melting Point

PVD is exceptionally versatile and can be used to deposit films of almost any inorganic material, including metals, ceramics, and alloys.

The process is capable of handling materials with extremely high melting points, up to 3500°C. The source material is vaporized, not necessarily fully melted, to create the coating.

The Resulting Coating's Properties

The final PVD coating is known for its exceptional durability and resistance to high temperatures.

These coatings also provide excellent resistance to abrasion, impact, and corrosion, making them suitable for demanding industrial applications.

Key Limitations to Consider

Line-of-Sight Deposition

The PVD process is "line-of-sight," meaning the vaporized material travels in a straight line from the source to the substrate.

This can make it challenging to coat complex internal geometries or surfaces that are not directly exposed to the material source.

Substrate Compatibility

While PVD works on a wide range of substrates, the process temperature (50-600°C) can be a limiting factor.

Substrates with low melting points or poor thermal stability may not be suitable for certain PVD processes.

Making the Right Choice for Your Application

- If your primary focus is creating a coating for high-temperature use: PVD is an excellent choice, as it can deposit robust ceramic or metallic films designed to withstand extreme heat.

- If your primary focus is depositing a specific high-melting-point material: The PVD process is fully capable of handling targets like tungsten or titanium nitride, which have very high melting points.

- If you are working with a heat-sensitive substrate: You must select a low-temperature PVD variant to ensure the substrate is not damaged during the coating process.

Ultimately, evaluating temperature in PVD requires you to distinguish between the process conditions and the final properties of the coating material.

Summary Table:

| Aspect | Temperature Range / Limit | Key Insight |

|---|---|---|

| PVD Process Temperature | 50°C to 600°C | The controlled temperature inside the chamber during coating. |

| Coating Material Melting Point | Up to 3500°C | PVD can deposit materials with extremely high melting points. |

| Substrate Limitation | Varies by material | The process temperature must be compatible with the substrate's thermal stability. |

Need a high-performance PVD coating for your application?

KINTEK specializes in advanced lab equipment and consumables for precise PVD processes. Whether you're working with high-temperature materials or heat-sensitive substrates, our expertise ensures optimal coating results.

Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and achieve superior coating performance.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition