At its core, Chemical Vapor Deposition (CVD) is a method for creating a solid, high-performance thin film on a surface. The process involves introducing precursor gases into a reaction chamber, where they undergo a chemical reaction triggered by high heat or plasma. This reaction causes a new material to deposit, atom by atom, onto a target substrate, effectively "growing" a new layer.

The crucial insight is that CVD is not a single action but a highly controlled engineering process. It uses a gaseous vapor as a raw material to construct a solid material directly onto a surface, offering precise control over the final film's thickness, composition, and properties.

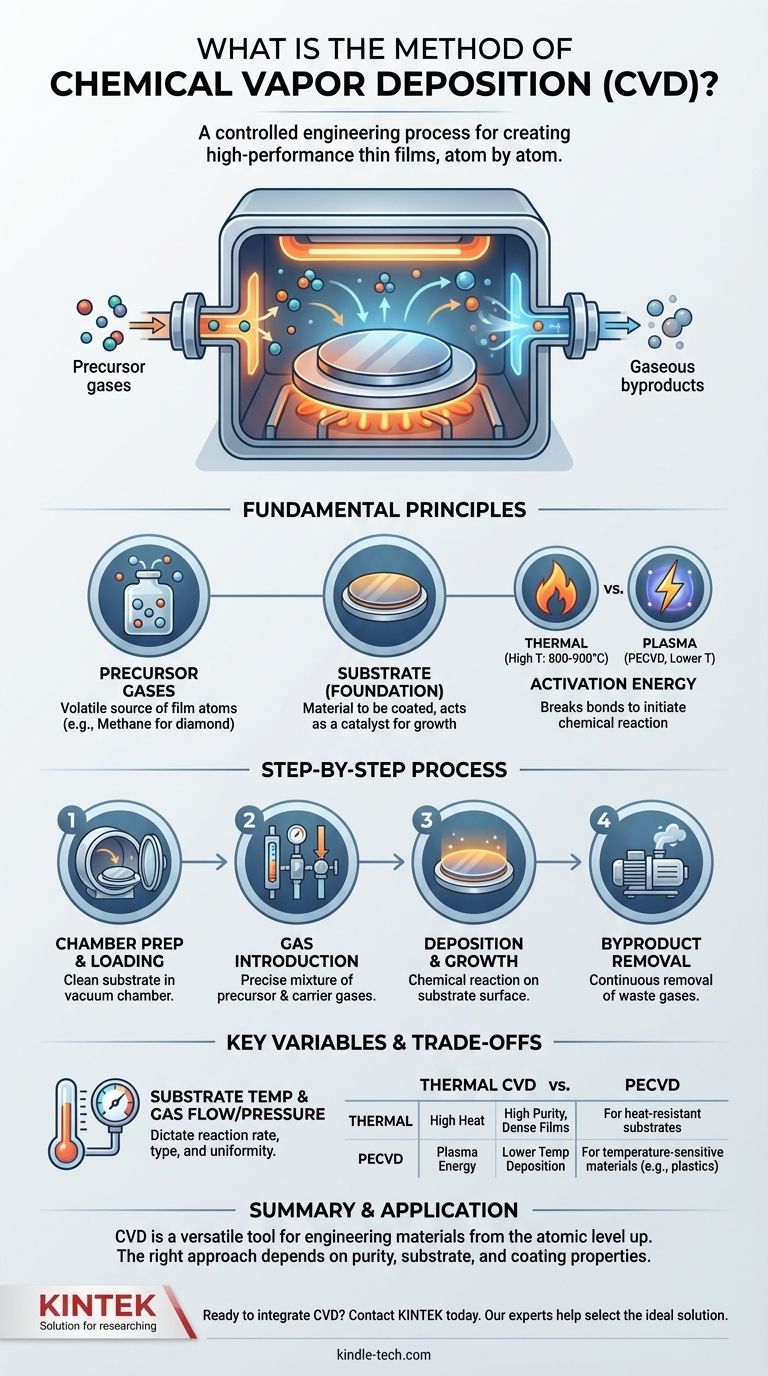

The Fundamental Principles of CVD

To truly understand the CVD method, we must look at its core components: the precursors, the substrate, and the activation energy that drives the entire process.

The Role of Precursor Gases

The process begins with one or more volatile precursor gases. These are specially chosen gases that contain the specific atoms needed for the final film.

For example, to create a diamond film, a carbon-rich gas like methane is used. These gases are often mixed with inert carrier gases that help transport them uniformly into the chamber.

The Substrate: The Foundation for Growth

The substrate is the material being coated. It is placed inside the reaction chamber and serves as the physical foundation for the new film.

Crucially, the substrate's surface often acts as a catalyst, providing the ideal location for the chemical reactions to occur and ensuring the deposited film adheres strongly.

The Crucial Step: Activating the Reaction

Gases will not spontaneously form a solid film. They require a significant input of energy to break their molecular bonds and initiate the chemical reaction.

This energy is typically supplied in one of two ways:

- Thermal Energy: The substrate is heated to very high temperatures (often 800-900°C). When the precursor gases touch the hot surface, they decompose and react.

- Plasma Energy: An energy field (like microwaves or radio frequency) is used to ionize the gases into a plasma. This plasma contains highly reactive particles that can form a film at much lower temperatures.

A Step-by-Step Breakdown of the Process

While there are many variations, the CVD method follows a consistent sequence of events to achieve a uniform and adherent coating.

Step 1: Chamber Preparation and Loading

The process takes place in a sealed, controlled vacuum chamber. The substrate (such as a silicon wafer or diamond seed) is carefully cleaned and placed inside.

Step 2: Introduction of Reactant Gases

A precise mixture of precursor and carrier gases is introduced into the chamber at a specific flow rate and pressure.

Step 3: Deposition on the Substrate

This is the heart of the process. As the energized gases interact with the substrate surface, they undergo a chemical reaction. The solid product of this reaction deposits onto the substrate, building up the thin film layer by layer.

Step 4: Removal of Byproducts

The chemical reaction also creates gaseous byproducts that are not part of the film. These waste gases are continuously pumped out of the chamber to prevent contamination and ensure a pure, high-quality deposition.

Understanding the Trade-offs and Key Variables

The final quality of a CVD coating is not accidental; it is the direct result of carefully controlling several critical variables. Mastering these trade-offs is key to successful deposition.

The Impact of Substrate Temperature

Temperature is arguably the most critical variable. It directly dictates the rate and type of chemical reaction that occurs on the substrate's surface. Too low, and the reaction won't start; too high, and you may damage the substrate or form undesirable materials.

The Role of Gas Flow and Pressure

The flow rate and pressure inside the chamber control the concentration of precursor molecules available for the reaction. These must be finely tuned to ensure the film grows uniformly across the entire substrate surface without defects.

Thermal CVD vs. Plasma-Enhanced CVD (PECVD)

The choice of how to energize the gases represents a fundamental trade-off.

Thermal CVD uses high heat. This often produces extremely pure, dense, and high-quality crystalline films. However, it can only be used on substrates that can withstand extreme temperatures without melting or warping.

Plasma-Enhanced CVD (PECVD) uses a plasma to drive the reaction. This allows deposition to occur at much lower temperatures, making it suitable for coating temperature-sensitive materials like plastics. However, the film structure may differ from that produced by high-temperature methods.

How to Apply This to Your Goal

The right CVD approach depends entirely on the material you are creating and the substrate you are coating.

- If your primary focus is the highest purity and crystalline quality: Thermal CVD is often the superior choice, provided your substrate can tolerate the required heat.

- If your primary focus is coating temperature-sensitive materials: Plasma-Enhanced CVD (PECVD) is the necessary approach to avoid damaging the underlying component.

- If your primary focus is a thick, durable, and strongly bonded coating: The CVD family of processes is an excellent choice for creating robust films for demanding applications.

Ultimately, Chemical Vapor Deposition is a versatile and precise tool for engineering materials from the atomic level up.

Summary Table:

| CVD Process Step | Key Component | Purpose |

|---|---|---|

| 1. Chamber Preparation | Vacuum Chamber | Creates a controlled, contaminant-free environment. |

| 2. Gas Introduction | Precursor Gases | Supplies the chemical building blocks for the thin film. |

| 3. Reaction Activation | Heat or Plasma | Provides energy to break molecular bonds and start the reaction. |

| 4. Film Deposition | Substrate Surface | The solid material forms atom-by-layer on the target surface. |

| 5. Byproduct Removal | Exhaust System | Vacuums away gaseous waste to ensure a pure, high-quality coating. |

Ready to Integrate CVD Technology into Your Lab?

Choosing the right deposition method is critical for your research and production quality. KINTEK specializes in providing high-performance lab equipment, including CVD systems, to meet the precise needs of laboratories and research facilities.

Our experts can help you select the ideal solution—whether you require high-temperature thermal CVD for superior purity or low-temperature PECVD for sensitive substrates—ensuring you achieve the exact film properties your project demands.

Contact KINTEK today to discuss your specific application and discover how our lab equipment can advance your work.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs