By a significant margin, the most common and widely used industrial ceramic is Aluminum Oxide, more commonly known as Alumina (Al₂O₃). Its ubiquity stems from a powerful combination of high performance, broad applicability, and cost-effectiveness that no other advanced ceramic can match for such a wide array of applications.

The core reason for Alumina's dominance is not that it is the best ceramic in any single category, but that it offers the most versatile and economical balance of desirable properties, making it the default, high-performance workhorse for countless industries.

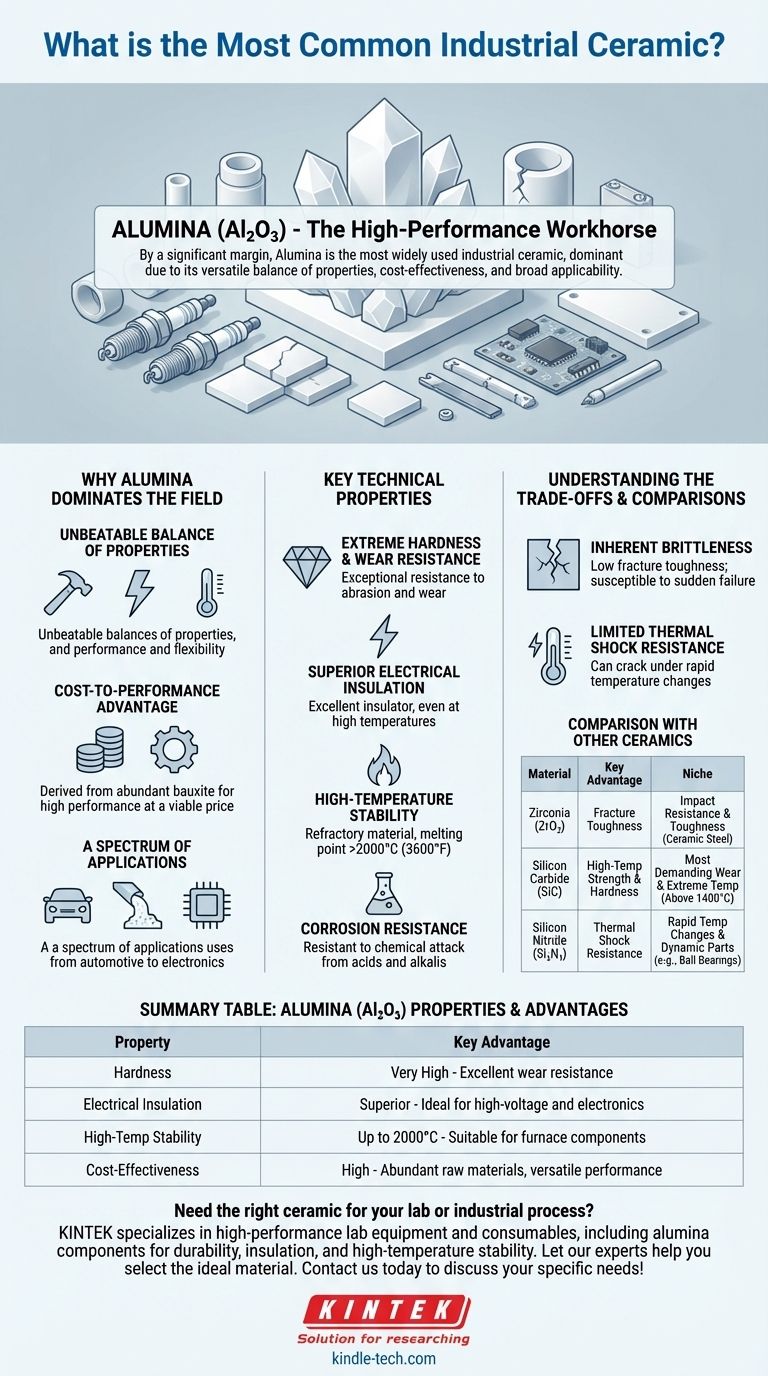

Why Alumina Dominates the Field

To understand the world of technical ceramics, one must first understand why Alumina is its foundation. Its leadership isn't accidental; it's a direct result of its inherent material characteristics and economic viability.

An Unbeatable Balance of Properties

Alumina provides a robust suite of valuable engineering properties in a single material. It is extremely hard, electrically insulating, reasonably strong under compression, and stable at high temperatures.

This versatile combination means it can solve many different engineering problems without the need for more specialized, exotic, and expensive materials.

The Cost-to-Performance Advantage

Alumina is derived from bauxite, an abundant and readily available ore. This makes refined, high-purity Alumina powders significantly less expensive to produce compared to materials like Silicon Nitride or Zirconia.

For engineers and designers, this translates to achieving high-performance characteristics—like extreme wear resistance or electrical insulation—at a commercially viable price point.

A Spectrum of Applications

The result of this balanced profile is a staggering range of uses. Alumina is found in everything from the spark plug insulators in your car to the wear-resistant linings in industrial chutes, from hip replacement joints to the substrate for microelectronics.

Key Technical Properties Explained

The value of any material is in its specific, measurable properties. Alumina's popularity is rooted in a few key characteristics that engineers consistently rely upon.

Extreme Hardness and Wear Resistance

With a hardness that is surpassed only by a few materials like diamond and silicon carbide, Alumina is exceptionally resistant to abrasion and wear.

This makes it ideal for components that experience friction or erosion, such as pump seals, grinding media, and thread guides in textile manufacturing.

Superior Electrical Insulation

Alumina is an excellent electrical insulator, maintaining its high resistivity even at elevated temperatures. This is a critical property that many metals and polymers lack.

It is the standard material for high-voltage insulators and is used extensively as a substrate for electronic circuits where electrical isolation is paramount.

High-Temperature Stability

As a refractory material, Alumina has a very high melting point (over 2000°C or 3600°F) and maintains good mechanical strength at high temperatures.

This allows it to be used for furnace components, thermocouple protection tubes, and other parts that must operate reliably in extreme heat.

Corrosion Resistance

Alumina exhibits excellent resistance to chemical attack from a wide range of acids and alkalis, particularly at room temperature. This allows it to be used in demanding chemical processing environments where metals would quickly corrode.

Understanding the Trade-offs

No material is perfect. Acknowledging Alumina's limitations is crucial for proper material selection and engineering design.

Inherent Brittleness

Like most ceramics, Alumina has low fracture toughness. This means it is brittle and can fail suddenly and catastrophically when subjected to sharp impacts or high tensile loads.

Designs must carefully manage stress concentrations and avoid impact loading to prevent component failure.

Limited Thermal Shock Resistance

While stable at high temperatures, Alumina can crack if subjected to rapid temperature changes. Its moderate thermal expansion coefficient and thermal conductivity make it more susceptible to thermal shock than materials like Silicon Nitride or Silicon Carbide.

Applications involving fast thermal cycling require careful analysis or the selection of an alternative ceramic.

How Alumina Compares to Other Ceramics

Understanding Alumina's position is clearer when compared to other major industrial ceramics, each of which fills a specific high-performance niche.

vs. Zirconia (Toughness)

Zirconia (ZrO₂) is known as "ceramic steel" for its exceptional fracture toughness, which is far superior to Alumina's. It is used when the primary requirement is resistance to cracking and fracture.

vs. Silicon Carbide (High-Temp Strength & Hardness)

Silicon Carbide (SiC) is even harder than Alumina and maintains its strength at extremely high temperatures (above 1400°C). It is chosen for the most demanding wear and high-temperature structural applications.

vs. Silicon Nitride (Thermal Shock)

Silicon Nitride (Si₃N₄) has outstanding thermal shock resistance, allowing it to survive rapid and severe temperature fluctuations that would shatter Alumina. It also possesses high toughness, making it suitable for dynamic parts like ceramic ball bearings.

Making the Right Choice for Your Application

Selecting the correct ceramic depends entirely on the primary demands of your project.

- If your primary focus is general-purpose wear resistance and electrical insulation at a low cost: Alumina is almost always the correct starting point and definitive choice.

- If your primary focus is maximum fracture toughness and impact resistance: Zirconia is the superior material, despite its higher cost.

- If your primary focus is extreme temperature stability and maximum hardness: Silicon Carbide is the material of choice for the most severe environments.

- If your primary focus is surviving rapid and extreme temperature changes: Silicon Nitride offers the best performance against thermal shock.

Ultimately, Alumina's status as the most common industrial ceramic is earned by its ability to provide exceptional performance for the widest range of problems at the most accessible cost.

Summary Table:

| Property | Alumina (Al₂O₃) | Key Advantage |

|---|---|---|

| Hardness | Very High | Excellent wear resistance |

| Electrical Insulation | Superior | Ideal for high-voltage and electronics |

| High-Temp Stability | Up to 2000°C | Suitable for furnace components |

| Cost-Effectiveness | High | Abundant raw materials, versatile performance |

Need the right ceramic for your lab or industrial process? KINTEK specializes in high-performance lab equipment and consumables, including alumina components tailored for durability, insulation, and high-temperature stability. Let our experts help you select the ideal material to enhance your efficiency and results. Contact us today to discuss your specific needs!

Visual Guide

Related Products

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

People Also Ask

- How hot can a metal surface get in the sun? The Surprising Science Behind Extreme Heat

- What are the properties and handling precautions for alumina powder as a polishing material? Achieve a Flawless Finish with Precision

- What is the maximum operating temperature of alumina? The Critical Role of Purity and Form

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What is the process of alumina tube manufacturing? From Powder to High-Performance Ceramic