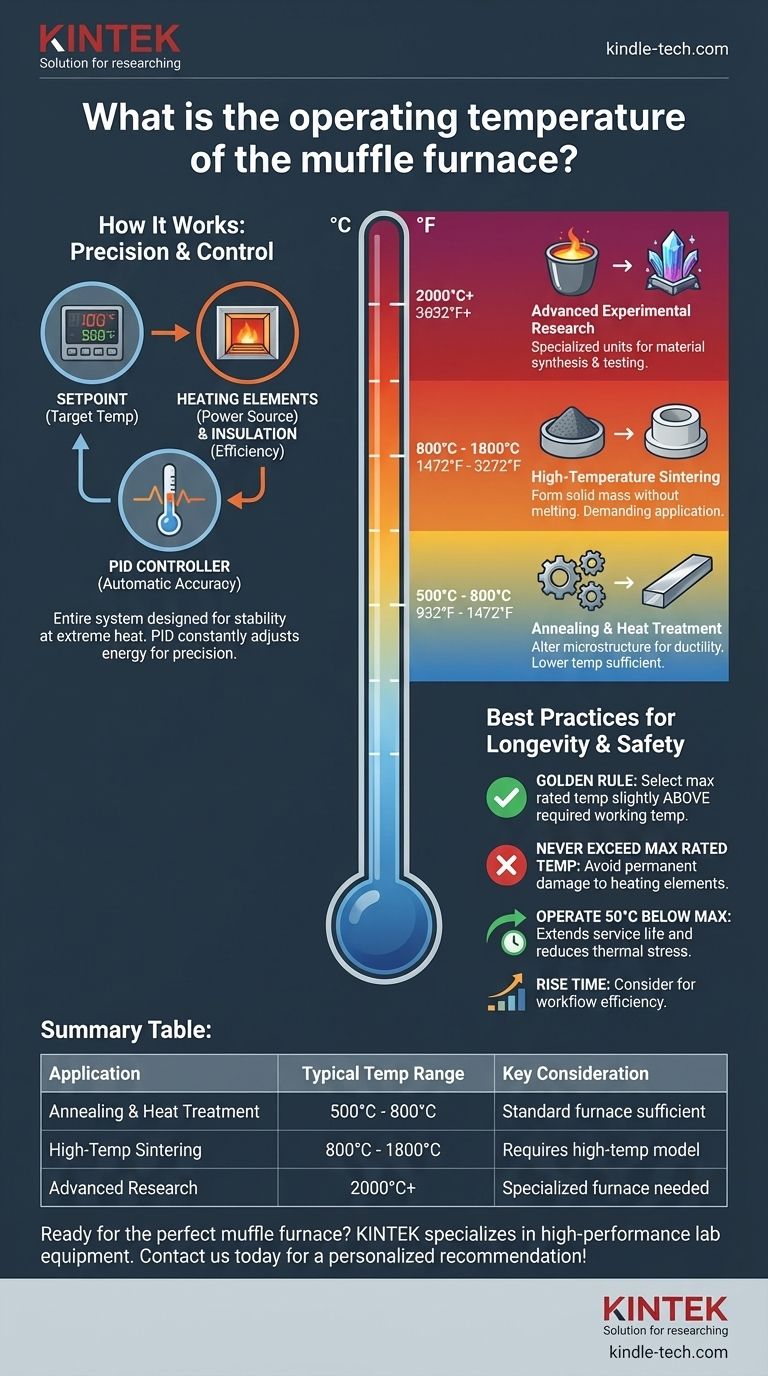

In short, a muffle furnace operates at very high temperatures, typically ranging from 800°C to 1800°C (1472°F to 3272°F). However, the precise operating temperature is not a single value but is determined entirely by the specific application, with some specialized models capable of exceeding 2000°C (3632°F).

The key isn't the furnace's maximum possible heat, but selecting a unit whose maximum rated temperature is slightly above your required working temperature. This ensures operational flexibility and significantly extends the life of the heating elements.

How Operating Temperature is Determined and Controlled

Understanding the furnace's capabilities begins with knowing how temperature is defined, achieved, and maintained. The entire system is designed for precision and stability at extreme heat.

The Role of the Temperature Setpoint

The temperature setpoint is the specific target temperature you program into the furnace controller. This value is dictated by the requirements of your process, whether it's for sintering a ceramic or annealing a metal alloy.

Achieving High Temperatures

The maximum temperature a furnace can reach is dictated by its heating elements. These components, often shielded by refractory materials to prevent heat loss, are the source of the furnace's power.

The chamber itself is lined with high-grade insulation, like refractory bricks, which is essential for both reaching the setpoint efficiently and maintaining that temperature with stability.

Ensuring Accuracy with Automatic Control

Modern muffle furnaces use sophisticated automatic controllers, often a PID (Proportional-Integral-Derivative) system. This controller constantly compares the actual temperature inside the chamber, measured by a thermocouple, to your setpoint.

It then precisely adjusts the energy supplied to the heating elements to correct for any deviation, ensuring the internal temperature remains stable and accurate throughout the process.

Matching Temperature to Your Application

The required operating temperature varies widely depending on the material and the desired outcome. Furnaces are typically chosen based on the process they will be used for.

Annealing and Heat Treatment

For processes like annealing, which alters a material's microstructure to make it more ductile, lower temperatures are often sufficient. This work typically falls within the 500°C to 800°C range.

High-Temperature Sintering

Sintering is the process of compacting and forming a solid mass of material by heat without melting it to the point of liquefaction. This demanding application requires a much higher temperature range, typically 800°C to 1800°C.

Advanced Experimental Research

For high-temperature material science and experimental research, specialized furnaces are available. These units can push the boundaries, reaching temperatures in excess of 2000°C for advanced material synthesis and testing.

Understanding the Trade-offs and Best Practices

Operating a muffle furnace correctly is critical for both safety and equipment longevity. The relationship between operating temperature and maximum temperature is the most important factor to manage.

Never Exceed the Rated Temperature

The single most important rule is to never operate the furnace above its maximum rated temperature. Doing so can permanently damage or destroy the electric heating elements, leading to costly and complex repairs.

Operate Below Maximum for Longevity

For consistent performance and to prolong the furnace's service life, it is a universal best practice to operate at least 50°C below the maximum rated temperature. This buffer reduces thermal stress on the heating elements and other critical components.

Consider the Rise Time

Rise time is the time it takes for the furnace to reach its maximum operating temperature from a cold start. This is a key performance specification to consider, as a slow rise time can impact lab or production workflow.

Making the Right Choice for Your Goal

Selecting the correct muffle furnace means matching its specifications to your intended process. Focus on your required working temperature, not the highest number you can find.

- If your primary focus is standard heat treatment or annealing: You will be best served by a furnace with a maximum rating comfortably above the 500°C to 800°C range.

- If your primary focus is material sintering or high-temperature testing: Look for models that can reliably operate up to 1800°C, ensuring you have a buffer for longevity.

- If your primary focus is cutting-edge material science: You will need a specialized, high-temperature furnace capable of exceeding 2000°C, built specifically for research applications.

By understanding your true operational needs, you can select a furnace that will perform reliably and efficiently for years to come.

Summary Table:

| Application | Typical Temperature Range | Key Consideration |

|---|---|---|

| Annealing & Heat Treatment | 500°C - 800°C | Standard furnace sufficient |

| High-Temp Sintering | 800°C - 1800°C | Requires high-temp model |

| Advanced Research | 2000°C+ | Specialized furnace needed |

Ready to find the perfect muffle furnace for your lab's temperature needs? KINTEK specializes in high-performance lab equipment, offering a range of muffle furnaces designed for precise temperature control and durability. Whether you're conducting heat treatment, sintering, or advanced research, our experts will help you select a unit that operates reliably within your required range. Contact us today to discuss your application and get a personalized recommendation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How do you calibrate a muffle furnace? Achieve Precise Temperature Control for Your Lab

- What is a muffle furnace in the environment? Achieve Clean, Contaminant-Free Heating

- What is a muffle furnace used for ash determination? Achieve Precise Inorganic Analysis

- Will brazing stick to cast iron? A Low-Heat Joining Solution for Crack-Free Repairs

- What temperature does steel liquify? Understanding the Melting Range for Your Applications