The power of an induction furnace is best understood as a combination of three distinct capabilities: its capacity for intense heat, its precision in process control, and its operational efficiency. It uses a highly reliable power supply to generate temperatures exceeding 1650°C for melting, while its underlying electromagnetic principles ensure a uniform temperature and material composition, minimizing waste and maximizing product quality.

The true "power" of an induction furnace is not just its electrical consumption, but its ability to convert that electricity into unparalleled control. It offers precise command over heating, melting, and mixing, which directly translates to higher quality products, less material waste, and lower overall production costs.

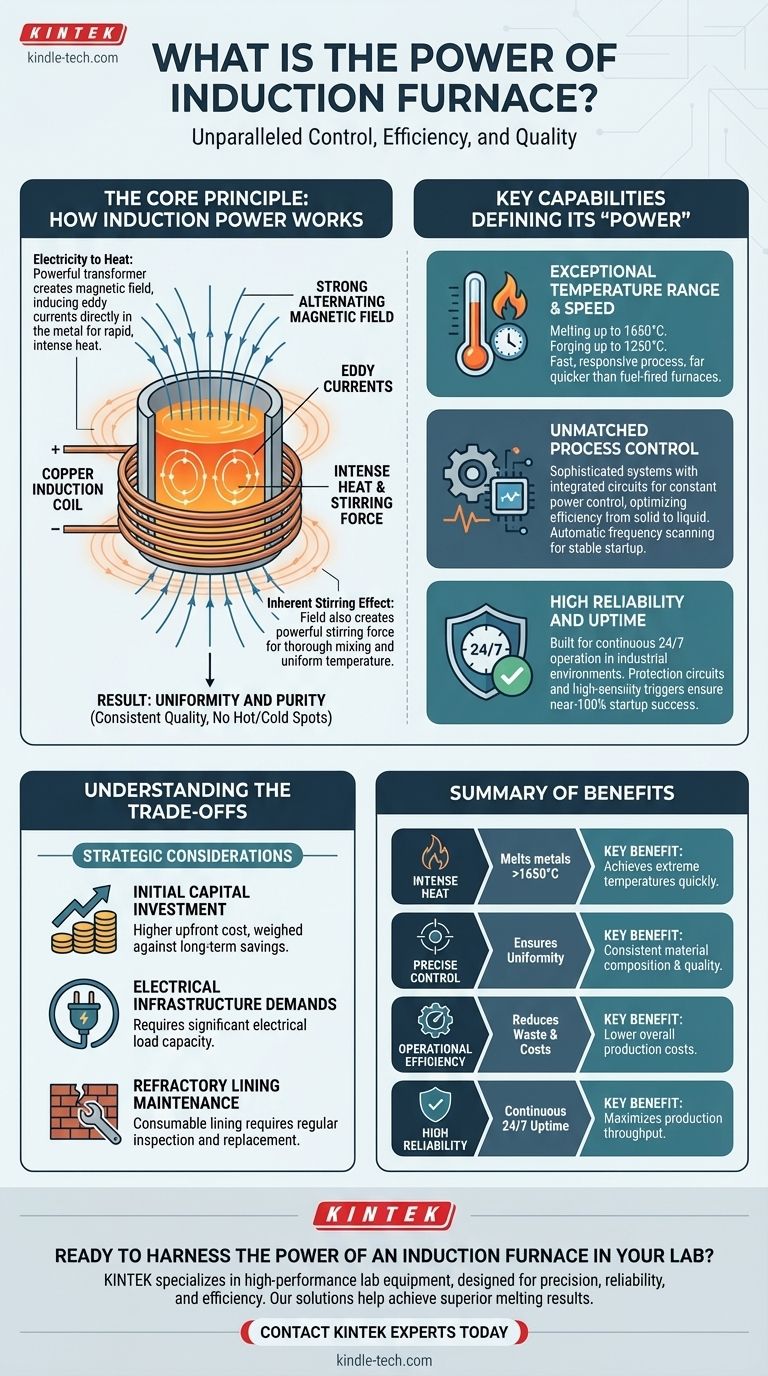

The Core Principle: How Induction Power Works

To understand the furnace's capabilities, you must first understand its method. It does not burn fuel; it uses electromagnetic principles to generate heat directly within the target material.

From Electricity to Heat

An induction furnace operates like a powerful transformer. The furnace's primary coil, powered by a specialized supply, creates a strong, alternating magnetic field. The metal placed inside the furnace (the charge) acts as a secondary coil. This magnetic field induces powerful electrical currents, known as eddy currents, directly within the metal. The metal's natural resistance to these currents generates rapid and intense heat.

The Inherent Stirring Effect

The same alternating magnetic field that induces heat also creates a powerful stirring force within the molten metal. This constant, gentle circulation ensures that alloying elements mix thoroughly and that the temperature remains remarkably uniform throughout the entire bath.

The Result: Uniformity and Purity

This combination of direct heating and electromagnetic stirring means the furnace produces molten metal of a highly consistent quality. There are no hot spots or cold spots, leading to a small temperature difference between the core and the surface of the melt and predictable, repeatable results.

Key Capabilities Defining Its "Power"

The furnace's design translates into several key operational strengths that define its power in a manufacturing context.

Exceptional Temperature Range & Speed

An induction furnace can achieve forging temperatures up to 1250°C and melting temperatures up to 1650°C. Because heat is generated directly within the material, the process is extremely fast and responsive, far more so than traditional fuel-fired furnaces.

Unmatched Process Control

Modern induction furnaces are managed by sophisticated control systems. These systems use integrated circuits to automatically adjust voltage and current based on the state of the furnace charge. This constant power control ensures optimal efficiency throughout the melt cycle, from solid to liquid. Functions like automatic frequency scanning ensure a smooth and stable startup every time.

High Reliability and Uptime

Designed for industrial environments, these systems are built for continuous, 24-hour operation. They incorporate comprehensive protection circuits for over-voltage, over-current, and other potential faults. Features like a high-sensitivity trigger circuit contribute to a near-100% startup success rate, maximizing uptime and production throughput.

Understanding the Trade-offs

While powerful, induction technology is not without its specific considerations. Objectivity requires acknowledging them.

Initial Capital Investment

Induction furnace systems, with their specialized power supplies and control units, typically require a higher upfront capital investment compared to simpler, traditional furnace types. This cost must be weighed against the long-term savings in material and energy.

Electrical Infrastructure Demands

These are high-power electrical devices. Your facility must have an electrical infrastructure capable of supporting the significant load. While modern designs include "soft start" features to minimize impact on the grid, the fundamental power requirement remains substantial.

Refractory Lining Maintenance

The furnace shell is lined with a refractory material that degrades over time due to extreme heat and contact with molten metal. This lining is a consumable component that requires regular inspection, maintenance, and eventual replacement, representing a key ongoing operational cost.

Making the Right Choice for Your Goal

The decision to use an induction furnace should be aligned with your primary production objectives.

- If your primary focus is product quality and consistency: The uniform heating and electromagnetic stirring effect make induction the superior choice for creating homogenous alloys.

- If your primary focus is high-volume, continuous production: The system's speed, reliability, and suitability for 24/7 operation provide a significant advantage in throughput.

- If your primary focus is reducing operating costs: The efficiency and reduction in wasted material can lead to significant long-term savings, justifying the initial investment.

Ultimately, the power of an induction furnace lies in its ability to serve as a strategic asset that gives you precise control over your entire heating or melting process.

Summary Table:

| Key Capability | Key Benefit |

|---|---|

| Intense Heat | Melts metals at temperatures exceeding 1650°C. |

| Precise Control | Ensures uniform temperature and material composition. |

| Operational Efficiency | Reduces material waste and lowers production costs. |

| High Reliability | Built for continuous 24/7 operation with high uptime. |

Ready to harness the power of an induction furnace in your lab?

KINTEK specializes in high-performance lab equipment, including induction furnaces designed for precision, reliability, and efficiency. Our solutions help laboratories achieve superior melting results, reduce waste, and enhance productivity.

Contact our experts today to find the perfect induction furnace for your specific needs and discover how KINTEK can power your success.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity