The pressed pellet technique is a fundamental sample preparation method used in X-ray Fluorescence (XRF) analysis. It involves grinding a sample into a fine powder, mixing it with a binding agent, and compressing the mixture under high pressure to form a solid, flat disc suitable for analysis.

The core purpose of the pressed pellet method is to transform a physically inconsistent sample into a perfectly flat, dense, and homogenous surface. This standardization is critical because it ensures the XRF instrument measures the true chemical composition of the material, not misleading artifacts from its physical form.

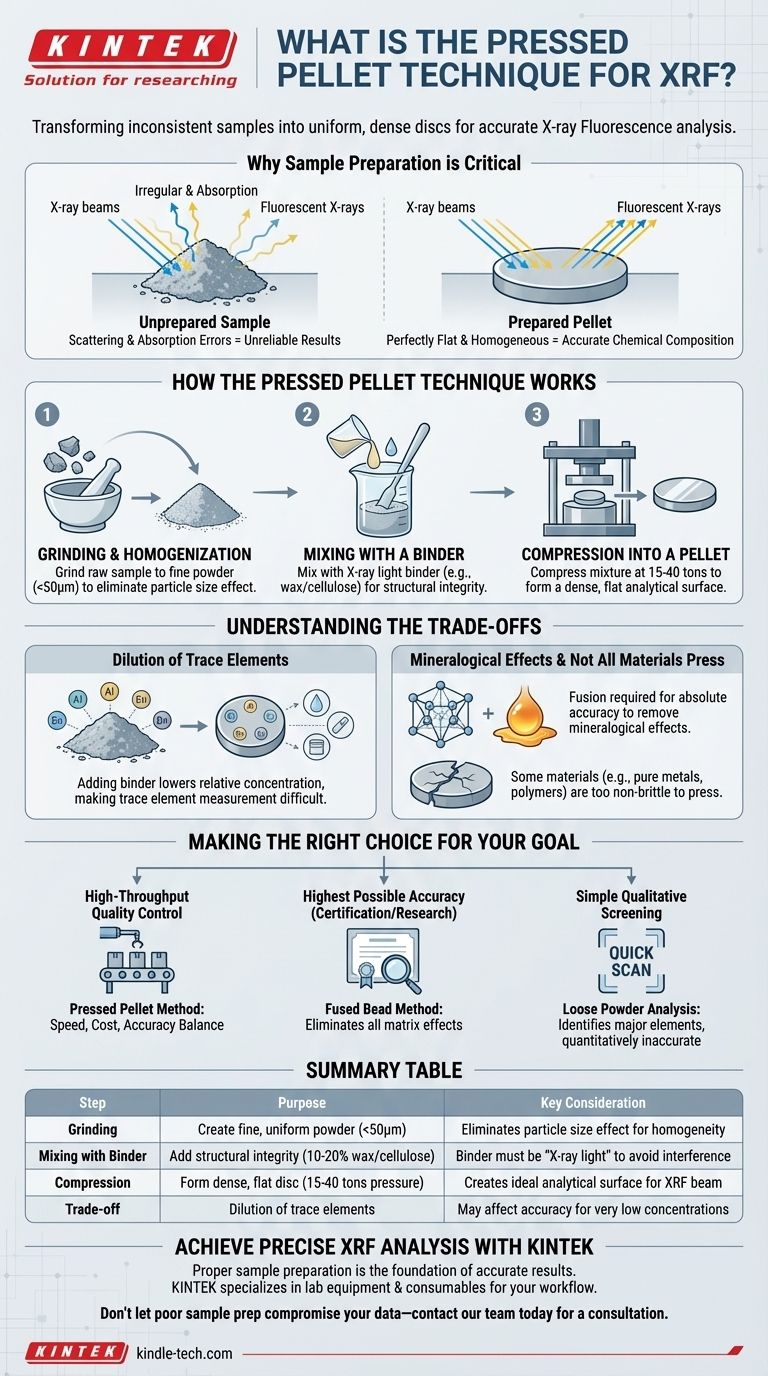

Why Sample Preparation is Critical for XRF

The Physics of XRF Demands a Perfect Surface

An XRF analyzer works by bombarding a sample with high-energy X-rays. This causes the elements within the sample to emit their own characteristic "fluorescent" X-rays, which are then measured by a detector.

The intensity of these fluorescent X-rays is directly proportional to the concentration of each element. However, this relationship only holds true if the sample surface is perfectly flat, smooth, and homogenous.

The Problem with Unprepared Samples

Analyzing a loose powder or an irregular solid object directly leads to significant errors. Issues like inconsistent particle size, surface voids, and roughness can scatter the primary X-rays and absorb the fluorescent X-rays unevenly.

This means the detector receives an inaccurate signal, leading to unreliable results. The analyzer ends up measuring the sample's poor physical state rather than its true elemental makeup.

How the Pressed Pellet Technique Works

Step 1: Grinding and Homogenization

The first and most critical step is to grind the raw sample into a very fine, uniform powder, typically smaller than 50 microns.

This process eliminates the particle size effect, where larger particles can disproportionately block the X-ray signals from smaller ones. Proper grinding ensures the sample is chemically homogenous.

Step 2: Mixing with a Binder

The fine powder is then thoroughly mixed with a binding agent. Binders are typically organic waxes or cellulosic materials that are "light" to the X-ray beam, meaning they contain no elements of analytical interest.

The binder acts as a lubricant during compression, helping particles flow and pack together tightly. It also provides structural integrity to the finished pellet.

Step 3: Compression into a Pellet

The powder-binder mixture is poured into a steel die set. The die is then placed in a hydraulic press and compressed at pressures between 15 and 40 tons.

This extreme pressure forces the particles into a dense, solid disc with a highly uniform and flat analytical surface, creating the ideal sample for the XRF instrument.

Understanding the Trade-offs

Dilution and Trace Elements

The primary trade-off is dilution. Adding a binder (typically 10-20% by weight) lowers the relative concentration of every element in the sample.

This can make it more difficult to accurately measure elements that are already present at very low, or trace, concentrations.

Mineralogical and Matrix Effects

While the pressed pellet method solves physical problems, it does not eliminate mineralogical effects. In this phenomenon, the way an element is chemically bound within a crystal structure can influence the X-rays it emits.

For the absolute highest accuracy, especially with complex geological materials, an alternative technique called fusion is required. Fusion involves dissolving the sample in a molten flux to create a glass disc, which completely removes all particle size and mineralogical effects.

Not All Materials Can Be Pressed

Some materials, like pure metals or certain polymers, are not brittle and cannot be effectively ground and pressed into a stable pellet. These materials require different preparation methods, such as being cut and lathed to create a flat surface.

Making the Right Choice for Your Goal

The pressed pellet technique is a powerful tool, but its suitability depends entirely on your analytical objective.

- If your primary focus is high-throughput quality control: The pressed pellet method is often the ideal choice, providing an excellent balance of speed, cost, and accuracy for routine analysis.

- If your primary focus is the highest possible accuracy for certification or research: You should consider the fused bead method, as it is the only way to completely eliminate mineralogical and particle size effects.

- If your primary focus is simple, qualitative screening: Analyzing unprepared loose powders might be sufficient to identify major elements, but you must accept that the results will not be quantitatively accurate.

Ultimately, mastering your sample preparation is the key to unlocking consistent, reliable, and accurate results from your XRF instrument.

Summary Table:

| Step | Purpose | Key Consideration |

|---|---|---|

| Grinding | Create fine, uniform powder (<50μm) | Eliminates particle size effect for homogeneity |

| Mixing with Binder | Add structural integrity (10-20% wax/cellulose) | Binder must be "X-ray light" to avoid interference |

| Compression | Form dense, flat disc (15-40 tons pressure) | Creates ideal analytical surface for XRF beam |

| Trade-off | Dilution of trace elements | May affect accuracy for very low concentrations |

Achieve precise and reliable XRF analysis with KINTEK.

Proper sample preparation is the foundation of accurate results. Whether your goal is high-throughput quality control or rigorous research, choosing the right technique is critical. KINTEK specializes in the lab equipment and consumables you need to master your workflow, from hydraulic presses and grinding mills to high-purity binders and die sets.

Our experts can help you select the ideal solution for your specific materials and accuracy requirements. Don't let poor sample prep compromise your data—contact our team today for a consultation and ensure your XRF analysis is a success.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What are the two classifications of press machines? Single Punch vs. Rotary Presses Explained

- What are the different pill presses? Choose the Right Machine for Your Lab or Production Scale

- What are the advantages of press working operation? Unlock High-Speed, Low-Cost Mass Production

- What are the different parts of a single punch tablet machine? The Core Components Explained

- What is the pressed pellet technique? A Guide to Creating Uniform Solid Samples from Powder